Description

Jiangsu Liangyi is professional manufacturer of 1.4550,X6CrNiNb18-10,X6CrNiNb1810,X6CrNiNb18.10 open die forging parts and seamless rolled steel forged rings from china

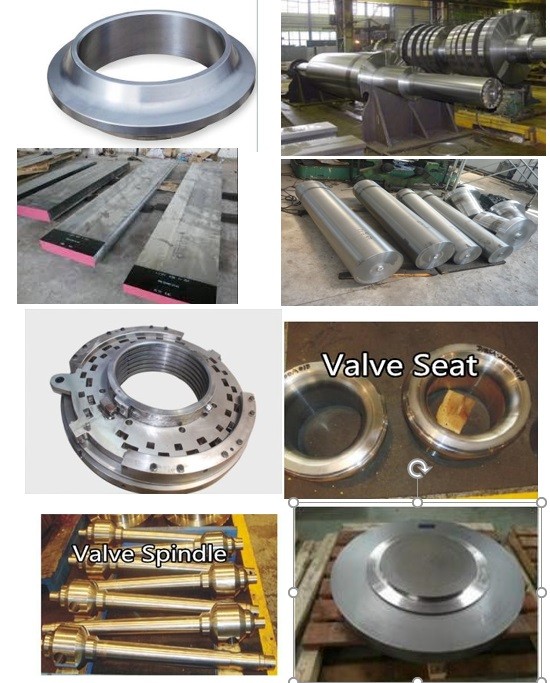

Following is the shape of 1.4550,X6CrNiNb18-10,X6CrNiNb1810,X6CrNiNb18.10 forging steel material that we could do is:X6CrNiNb18-10 Forged Steel round bars square bars Flat bars Rectangles Bars Rods,X6CrNiNb18.10 Forged forging steel rings seamless rolled rings,1.4550 Forged Forging Steel Hubs housing shell Sleeves Bushes Bushing Cases Hollow Bars,1.4550 Forged Forging Steel Discs Disks Blocks plates,X6CrNiNb18-10 Forged Forging Steel Pipe Tubes Tubings Piping Shells Casings Case barrels Housings.

Following is forging products of 1.4550,X6CrNiNb18-10,X6CrNiNb1810,X6CrNiNb18.10 material that is used in following industry

X6CrNiNb18-10 Forged Forging Valve Balls,valve Bonnets,valve Body Bodies ,valve Stems,valve closures, valve seat rings, valve core, valve discs,for H type two way 2‐way one way back pressure valves, ball valve,check valve,gate valve

X6CrNiNb18.10 Forged Forging Steel Butterfly Valve Main Shafts Spindles

1.4550 Forged Forging Swept branches outlets steel fittings swept saddles

X6CrNiNb18-10 Forged Forging downhole drilling tool Mud Motor Splined Drive shafts,Down hole Electric electrical submersible pumps ESP motor Splined Shaft

X6CrNiNb18.10 Forged Forging Steels Christmas Trees wellhead Spool Body Bodies cylinder

1.4550 Forged Forging venturi cone meter Body Bodies Blocks

1.4550 Forged Forging Steel gate valves Body Bodies bespoke flat bars

X6CrNiNb18-10 forged steel Flowseal cryogenic High Performance BV Butterfly Valves HPBV shaft

X6CrNiNb18-10 forging steel Oil measurement valve Spool Ultrasonic flow meter bodies Body

X6CrNiNb18.10 Forged Forging Steel double studded adapter flange

X6CrNiNb18.10 Forged Forging Steel integral Mud Flange Flanged outlet Studded crosses

1.4550 Forged Forging Steel Casing Heads,Tubing Heads,Casing Hangers,Tubing Hangers,Tubing Spools,Casing Spools,Spacer Spools

X6CrNiNb18.10 Forged Forgig Steel nuclear reactor coolant pump Casing Shells body bodis blocks,nuclear reactor coolant pumps containment seal chamber Rooms,nuclear reactor coolant pumps containment seal chamber Rooms

X6CrNiNb18.10 Forged Forging turbomachinery turbo centrifugal compressor Impeller,Compressor Shrouded Impellers

X6CrNiNb18.10 Forged Forging Steel Forged Single Double Bossed boss Blanks FLANGED BOSSES

X6CrNiNb18.10 Forged Forging Steel PUMP Casing cover.PUMP BARREL,pump impeller,pump shafts, pump housing, pump shells,pump body,pump wear rings,pump case casing.

1.4550 Forged Forging forge Steel transition Cone

1.4550 Forged Forging Steel Pressure Vessel Reactor Nozzles

X6CrNiNb18-10 forged forging steel pipes tubes shells piping tubing barrels housing, tube sheets,baffle plates, nozzles, channel flanges for boiler, heat exchanger,pressure vessel,reactors, heaters

1.4550 is used in the chemical industry equipment manufacturing nitric acid and derivatives, salts and fertilizers. Also used in cryotechnics, in the pharmaceutical industry, in the food industry - in food processing plants, dairies, sugar factories, breweries, in the fuel industry, i.e. in refineries and petrochemical plants.

FOllowing is production standard of 1.4550 forged material

EN 10088-3: 2005 Stainless steels. Technical delivery conditions for semi-finished products, bars, rods, wire, sections and bright products of corrosion resisting steels for general purposes

EN 10028-7: 2007 Flat products made of steels for pressure purposes. Stainless steels

EN 10222-5: 2000 Steel forgings for pressure purposes. Martensitic, austenitic and austenitic-ferritic stainless steels

EN 10216-5: 2014 Seamless steel tubes for pressure purposes. Technical delivery conditions. Stainless steel tubes

EN 10250-4: 2000 Open steel die forgings for general engineering purposes. Stainless steels

EN 10297-2: 2005 Seamless circular steel tubes for mechanical and general engineering purposes. Stainless steel. Technical delivery conditions

EN 10088-1: 2005 Stainless steels. List of stainless steels

EN 10088-5: 2009 Stainless steels. Technical delivery conditions for bars, rods, wire, sections and bright products of corrosion resisting steels for construction purposes

For melting 1.4550,X6CrNiNb18-10 forging steel gas turbine blade steel, we have following melting equipment

60 t Electric Arc Furnace (EAF) / Power 40 MVA

2 Ladle Furnace (LF)

2 Tank Degassing VD - VOD type

Pits for bottom pouring

ESR Plant (max weight 32 t)

FOllowing is chemical compostion of X6CrNiNb18.10 forged steel rings

C max 0.08

Si max 1

Mn max 2

Ni 9 - 12

P max 0.045

S max 0.015

Cr 17 - 19

Nb max 1

Following of X6CrNiNb18-10 forging parts heat treatment mechanical property Delivery condition :

Rm - Tensile strength (MPa) (+A) 500-740

Rm - Tensile strength (MPa) (+AT) 510-740

Rp0.2 0.2% proof strength (MPa) (+AT) 205

Rp0.2 0.2% proof strength (MPa) (+A) 200-240

A - Min. elongation at fracture (%) (+A) 30-40

A - Min. elongation at fracture (%) longitud., (+AT) 35

Brinell hardness (HB): (+A) 230

Brinell hardness (HB): (+AT) 210

Following is inspection standard of 1.4550,X6CrNiNb18-10 forged pipes

ASTM A-370(Latest Edition): Test methods & Definitions for mechanical testing of steel products.

ASTM E8 (Latest Edition): Standard Test Methods for Tension Testing of Metallic Materials 2.8 ISO 6892-1(Latest Edition): Metallic Materials - Tensile Testing Part 1 Method Of Test AtRoom Temperature.

ISO 6506-1(Latest Edition): Metallic Materials - Brinell Hardness Test

ISO 6508-1(Latest Edition): Metallic Materials -- Rockwell Hardness Test

ISO 6507-1(Latest Edition): Metallic Materials -- Vickers Hardness Test

ASTM E10 (Latest Edition): Standard Test Method For Brinell Hardness Of Metallic Materials

ASTM E18 (Latest Edition): Standard Test Method For Rockwell Hardness Of Metallic Materials

ASTM E384 (Latest Edition): Standard Test Method For Knoop & Vickers Hardness Of Metallic Materials

ASTM A-388/388M (Latest Edition): Specification for Ultrasonic Examination of heavy steel Forgings.

ASTM E 415(Latest Edition): Standard Test Method for Analysis of Carbon and Low-Alloy Steel by Spark Atomic Emission Spectrometry

ASTM A751 (Latest Edition): Standard Test Methods And Practices For Chemical Analysis Of Steel Product

ASTM E1086 (Latest Edition): Standard Test Method for Analysis of Austenitic Stainless Steel by Spark Atomic Emission Spectrometry

ASTM E23 (Latest Edition): Standard Test Method For Notched Bar Impact Testing Of Metallic Materials

INSP/MSC/10 (Latest Revision): Procedure for Visual Examination

HTQR/MSC/01 (Latest Revision): Heat Treatment Equipment Qualification Requirement

ASTM E2375 (Latest Revision): Standard Practice for Ultrasonic Testing of Wrought Products

ASTM E127 (Latest Revision): Standard Practice for Fabrication and Control of Flat Bottomed Hole Ultrasonic Standard Reference Blocks

ASTM E428 (Latest Revision): Standard Practice for Fabrication and Control of metal, other than aluminum, reference block used in Ultrasonic Testing

Qualification of manufacturing procedure of 1.4550,X6CrNiNb18-10 forging parts

The Manufacturing Process Plan (MPP) shall be submitted to the approval of clients Material

& Process Engineering dept. clients before qualification procedure begins. It shall detail at least

the following:

• type of ingot (supplier, manufacturing process, dimensions, and tests to beperformed);

• forging process;

• heat treatment process;

• tests on component.

In general, dissection of the first piece within the terms detailed in the part specification is required.

This activity may be omitted, upon decision of clients, if the supplier has already proven to be able to successfully produce components of similar shape, dimensions and manufacturing

process.

Welcome your inquiry of 1.4550,X6CrNiNb18-10,X6CrNiNb1810,X6CrNiNb18.10 forging forged steel parts

Following is the shape of 1.4550,X6CrNiNb18-10,X6CrNiNb1810,X6CrNiNb18.10 forging steel material that we could do is:X6CrNiNb18-10 Forged Steel round bars square bars Flat bars Rectangles Bars Rods,X6CrNiNb18.10 Forged forging steel rings seamless rolled rings,1.4550 Forged Forging Steel Hubs housing shell Sleeves Bushes Bushing Cases Hollow Bars,1.4550 Forged Forging Steel Discs Disks Blocks plates,X6CrNiNb18-10 Forged Forging Steel Pipe Tubes Tubings Piping Shells Casings Case barrels Housings.

Following is forging products of 1.4550,X6CrNiNb18-10,X6CrNiNb1810,X6CrNiNb18.10 material that is used in following industry

X6CrNiNb18-10 Forged Forging Valve Balls,valve Bonnets,valve Body Bodies ,valve Stems,valve closures, valve seat rings, valve core, valve discs,for H type two way 2‐way one way back pressure valves, ball valve,check valve,gate valve

X6CrNiNb18.10 Forged Forging Steel Butterfly Valve Main Shafts Spindles

1.4550 Forged Forging Swept branches outlets steel fittings swept saddles

X6CrNiNb18-10 Forged Forging downhole drilling tool Mud Motor Splined Drive shafts,Down hole Electric electrical submersible pumps ESP motor Splined Shaft

X6CrNiNb18.10 Forged Forging Steels Christmas Trees wellhead Spool Body Bodies cylinder

1.4550 Forged Forging venturi cone meter Body Bodies Blocks

1.4550 Forged Forging Steel gate valves Body Bodies bespoke flat bars

X6CrNiNb18-10 forged steel Flowseal cryogenic High Performance BV Butterfly Valves HPBV shaft

X6CrNiNb18-10 forging steel Oil measurement valve Spool Ultrasonic flow meter bodies Body

X6CrNiNb18.10 Forged Forging Steel double studded adapter flange

X6CrNiNb18.10 Forged Forging Steel integral Mud Flange Flanged outlet Studded crosses

1.4550 Forged Forging Steel Casing Heads,Tubing Heads,Casing Hangers,Tubing Hangers,Tubing Spools,Casing Spools,Spacer Spools

X6CrNiNb18.10 Forged Forgig Steel nuclear reactor coolant pump Casing Shells body bodis blocks,nuclear reactor coolant pumps containment seal chamber Rooms,nuclear reactor coolant pumps containment seal chamber Rooms

X6CrNiNb18.10 Forged Forging turbomachinery turbo centrifugal compressor Impeller,Compressor Shrouded Impellers

X6CrNiNb18.10 Forged Forging Steel Forged Single Double Bossed boss Blanks FLANGED BOSSES

X6CrNiNb18.10 Forged Forging Steel PUMP Casing cover.PUMP BARREL,pump impeller,pump shafts, pump housing, pump shells,pump body,pump wear rings,pump case casing.

1.4550 Forged Forging forge Steel transition Cone

1.4550 Forged Forging Steel Pressure Vessel Reactor Nozzles

X6CrNiNb18-10 forged forging steel pipes tubes shells piping tubing barrels housing, tube sheets,baffle plates, nozzles, channel flanges for boiler, heat exchanger,pressure vessel,reactors, heaters

1.4550 is used in the chemical industry equipment manufacturing nitric acid and derivatives, salts and fertilizers. Also used in cryotechnics, in the pharmaceutical industry, in the food industry - in food processing plants, dairies, sugar factories, breweries, in the fuel industry, i.e. in refineries and petrochemical plants.

FOllowing is production standard of 1.4550 forged material

EN 10088-3: 2005 Stainless steels. Technical delivery conditions for semi-finished products, bars, rods, wire, sections and bright products of corrosion resisting steels for general purposes

EN 10028-7: 2007 Flat products made of steels for pressure purposes. Stainless steels

EN 10222-5: 2000 Steel forgings for pressure purposes. Martensitic, austenitic and austenitic-ferritic stainless steels

EN 10216-5: 2014 Seamless steel tubes for pressure purposes. Technical delivery conditions. Stainless steel tubes

EN 10250-4: 2000 Open steel die forgings for general engineering purposes. Stainless steels

EN 10297-2: 2005 Seamless circular steel tubes for mechanical and general engineering purposes. Stainless steel. Technical delivery conditions

EN 10088-1: 2005 Stainless steels. List of stainless steels

EN 10088-5: 2009 Stainless steels. Technical delivery conditions for bars, rods, wire, sections and bright products of corrosion resisting steels for construction purposes

For melting 1.4550,X6CrNiNb18-10 forging steel gas turbine blade steel, we have following melting equipment

60 t Electric Arc Furnace (EAF) / Power 40 MVA

2 Ladle Furnace (LF)

2 Tank Degassing VD - VOD type

Pits for bottom pouring

ESR Plant (max weight 32 t)

FOllowing is chemical compostion of X6CrNiNb18.10 forged steel rings

C max 0.08

Si max 1

Mn max 2

Ni 9 - 12

P max 0.045

S max 0.015

Cr 17 - 19

Nb max 1

Following of X6CrNiNb18-10 forging parts heat treatment mechanical property Delivery condition :

Rm - Tensile strength (MPa) (+A) 500-740

Rm - Tensile strength (MPa) (+AT) 510-740

Rp0.2 0.2% proof strength (MPa) (+AT) 205

Rp0.2 0.2% proof strength (MPa) (+A) 200-240

A - Min. elongation at fracture (%) (+A) 30-40

A - Min. elongation at fracture (%) longitud., (+AT) 35

Brinell hardness (HB): (+A) 230

Brinell hardness (HB): (+AT) 210

Following is inspection standard of 1.4550,X6CrNiNb18-10 forged pipes

ASTM A-370(Latest Edition): Test methods & Definitions for mechanical testing of steel products.

ASTM E8 (Latest Edition): Standard Test Methods for Tension Testing of Metallic Materials 2.8 ISO 6892-1(Latest Edition): Metallic Materials - Tensile Testing Part 1 Method Of Test AtRoom Temperature.

ISO 6506-1(Latest Edition): Metallic Materials - Brinell Hardness Test

ISO 6508-1(Latest Edition): Metallic Materials -- Rockwell Hardness Test

ISO 6507-1(Latest Edition): Metallic Materials -- Vickers Hardness Test

ASTM E10 (Latest Edition): Standard Test Method For Brinell Hardness Of Metallic Materials

ASTM E18 (Latest Edition): Standard Test Method For Rockwell Hardness Of Metallic Materials

ASTM E384 (Latest Edition): Standard Test Method For Knoop & Vickers Hardness Of Metallic Materials

ASTM A-388/388M (Latest Edition): Specification for Ultrasonic Examination of heavy steel Forgings.

ASTM E 415(Latest Edition): Standard Test Method for Analysis of Carbon and Low-Alloy Steel by Spark Atomic Emission Spectrometry

ASTM A751 (Latest Edition): Standard Test Methods And Practices For Chemical Analysis Of Steel Product

ASTM E1086 (Latest Edition): Standard Test Method for Analysis of Austenitic Stainless Steel by Spark Atomic Emission Spectrometry

ASTM E23 (Latest Edition): Standard Test Method For Notched Bar Impact Testing Of Metallic Materials

INSP/MSC/10 (Latest Revision): Procedure for Visual Examination

HTQR/MSC/01 (Latest Revision): Heat Treatment Equipment Qualification Requirement

ASTM E2375 (Latest Revision): Standard Practice for Ultrasonic Testing of Wrought Products

ASTM E127 (Latest Revision): Standard Practice for Fabrication and Control of Flat Bottomed Hole Ultrasonic Standard Reference Blocks

ASTM E428 (Latest Revision): Standard Practice for Fabrication and Control of metal, other than aluminum, reference block used in Ultrasonic Testing

Qualification of manufacturing procedure of 1.4550,X6CrNiNb18-10 forging parts

The Manufacturing Process Plan (MPP) shall be submitted to the approval of clients Material

& Process Engineering dept. clients before qualification procedure begins. It shall detail at least

the following:

• type of ingot (supplier, manufacturing process, dimensions, and tests to beperformed);

• forging process;

• heat treatment process;

• tests on component.

In general, dissection of the first piece within the terms detailed in the part specification is required.

This activity may be omitted, upon decision of clients, if the supplier has already proven to be able to successfully produce components of similar shape, dimensions and manufacturing

process.

Welcome your inquiry of 1.4550,X6CrNiNb18-10,X6CrNiNb1810,X6CrNiNb18.10 forging forged steel parts