Description

Jiangsu Liangyi is professional manufacturer of Incoloy 903,UNS N19903,Alloy 903,Incoloy ALloy 903 open die forging parts and seamless rolled steel forged rings from china

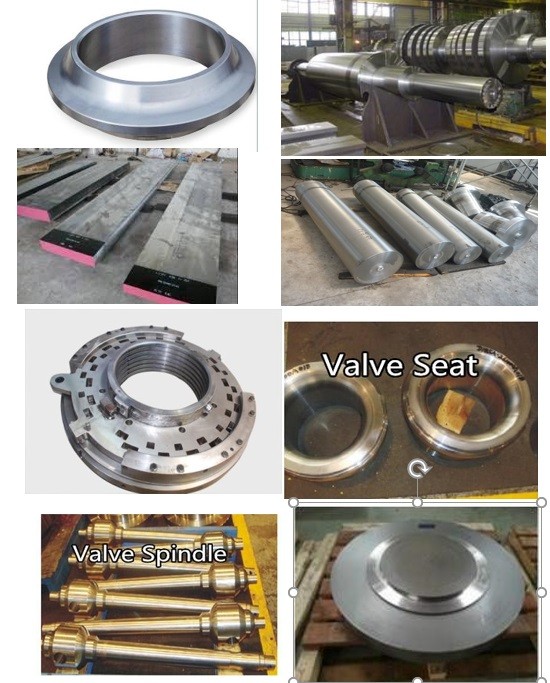

Following is the shape of Incoloy 903,UNS N19903,Alloy 903,Incoloy ALloy 903 forging steel material that we could do is:Incoloy 903 Forged Steel round bars square bars Flat bars Rectangles Bars Rods,Incoloy ALloy 903 Forged forging steel rings seamless rolled rings,Alloy 903 Forged Forging Steel Hubs housing shell Sleeves Bushes Bushing Cases Hollow Bars,UNS N19903 Forged Forging Steel Discs Disks Blocks plates,Incoloy 903 Forged Forging Steel Pipe Tubes Tubings Piping Shells Casings Case barrels Housings.

Following is forging products of Incoloy 903,UNS N19903,,Alloy 903,Incoloy ALloy 903 material that is used in following industry

Alloy 903 Forged Forging Turbine and Compressor Labyrinth Shaft Seals

Incoloy 903 Forged Forging Valve Balls,valve Bonnets,valve Body Bodies ,valve Stems,valve closures, valve seat rings, valve core, valve discs,for H type two way 2‐way one way back pressure valves, ball valve,check valve,gate valve

Alloy 903 Forged Forging Steel nuclear Power reactor coolant pumps Rotor Impellers

Incoloy ALloy 903 Forged Forgig Steel nuclear reactor coolant pump Casing Shells body bodis blocks,nuclear reactor coolant pumps containment seal chamber Rooms,nuclear reactor coolant pumps containment seal chamber Rooms

Incoloy ALloy 903 Forged Forging turbomachinery turbo centrifugal compressor Impeller,Compressor Shrouded Impellers

Incoloy ALloy 903 Forged Forging Steel PUMP Casing cover.PUMP BARREL,pump impeller,pump shafts, pump housing, pump shells,pump body,pump wear rings,pump case casing.

Alloy 903 Forged Forging Gas steam turbine disks, turbine impeller,turbine blisk,turbine discs,turbine wheel discs

Incoloy ALloy 903 Forging Steel Forging Forged Gas Steam Turbine Doubled-headed Double end Studs Fasteners Bolts bolting

Incoloy ALloy 903 Forging Steel gas steam Turbine Guide Rings,seal rings Labyrinth Rings Packing Seal Diaphragm & Seal Ring Rotor End Rings contours Casing Rings

Incoloy ALloy 903 Forged Forging Steel Gas Steam turbine diaphragm diapharagm nozzles

Incoloy 903 Forged Forging Gas Turbine LPT 1st & 2st 2nd Stg Stage Turbine Case Casings

Incoloy 903 Forged Forging Steel power plant steam turbine control reheat valve disc Disk

UNS N19903 Forged forging Gas Steam Turbine Valve Spindles/Stems/Rods,

Incoloy 903 Forging Steel Gas Steam Turbine MSV/GV/CV/CRV Valve Seats, Valve Cores, Valve Sleeves Spools,,Main Steam Valve Covers Bonnets Sleeves

Incoloy 903 forged forging steel pipes tubes shells piping tubing barrels housing, tube sheets,baffle plates, nozzles, channel flanges for boiler, heat exchanger,pressure vessel,reactors, heaters

Incoloy 903 is an agehardenable nickel-iron-cobalt alloy whose outstanding characteristics are a constant low coefficient of thermal expansion, a constant modulus of elasticity, and high strength.

Incoloy 903’s characteristics make it an excellent candidate for applications such as rocket-engine thrust chambers, steam-turbine bolts, springs, gage blocks, and ordnance hardware.

FOllowing is chemical compostion of Incoloy ALloy 903 forged rings

Nickel ..........................................................................36.0-40.0

Cobalt..........................................................................13.0-17.0

Aluminum ....................................................................0.30-1.15

Titanium.......................................................................1.00-1.85

Niobium.......................................................................2.40-3.50

Iron ...............................................................................Balance

Following is heat treament of alloy 903 forged parts

heat treated at 844°C (1550°F) for 1 hr. It is then quenched in water and aged at 719°C (1325°F) for 8 h followed by cooling. It is again aged at 622°C (1150°F) for 8 h followed by cooling in air.

Following of Incoloy 903 forging parts heat treatment nechanical property Delivery condition :

Tensile strength (precipitation hardened) 1310 MPa 190000 psi

Yield strength (@ strain 0.200 %, precipitation hardened) 1100 MPa 160000 psi

Elastic modulus (@ 0°C/32°F) 146.8 GPa 21290 ksi

Poisson's ratio (@ 250°C/482°F) 0.226 0.226

Elongation at break (precipitation hardened) 14% 14%

The following NDT inspections shall be performed after all heat treatments are performed

Visual inspection of all Incoloy 903 forging round bars

UT of all Incoloy 903 flat bars as per SEP 1923,inspection number D3 or D2 with dual (twin crystal search unit.100% of the volume shall be examined with the stipulated ecording level

Criteria stipulated in SEP 1923 quality class 2 b shall be applied with following modification:EE(single echo)and VE(numerous single echoes)without extension ≥2mm KSR are not permitted Defects above the recording limit shall be marked and it shall be ensured that these Incoloy 903 forging flat bars are not included in the lot delivered.

Following is inspection standard of Alloy 903 forged parts

ASTM A604 Standard test methods for macroetch testing of consumable electrode

remelted steel bars and billets

ASTM E112 Standard test methods for determining average grain size

EN ISO 6892-1:20 Metallic materials -Tensile testing -Part 1:Method of test at ambient temperature

ISO 204:2009 Metallic materials -Uniaxial creep testing in tension -Method of test

EN 10204 Metallic products -Types of inspection documents

EN ISO/IEC 17050:2004 Conformity assessment -Supplier's declaration of conformity -General requirements

All our Incoloy 903 forged material must give the material a required purity necessary for the application in following melting methods

one is triple melted material,VIM+ESR+VAR., the another one is double melted material,VIM+VAR.

All our UNS N19903 forging material shall be thoroughly worked,homogenous and free from blisters, cracks and injurious slag inclusions.

reported.

MARKING of our finished forged Incoloy 903 bars

Each part shall be stamped with:

The purchaser's part number

The purchaser's purchase number

The individual number

The heat number,if traceability to heat number is not possible by the individual number

The marking shall be surrounded by a frame or painted over with white durable paint.

Welcome your inquiry of Incoloy 903,UNS N19903,,Alloy 903,Incoloy ALloy 903) forging forged steel parts

Following is the shape of Incoloy 903,UNS N19903,Alloy 903,Incoloy ALloy 903 forging steel material that we could do is:Incoloy 903 Forged Steel round bars square bars Flat bars Rectangles Bars Rods,Incoloy ALloy 903 Forged forging steel rings seamless rolled rings,Alloy 903 Forged Forging Steel Hubs housing shell Sleeves Bushes Bushing Cases Hollow Bars,UNS N19903 Forged Forging Steel Discs Disks Blocks plates,Incoloy 903 Forged Forging Steel Pipe Tubes Tubings Piping Shells Casings Case barrels Housings.

Following is forging products of Incoloy 903,UNS N19903,,Alloy 903,Incoloy ALloy 903 material that is used in following industry

Alloy 903 Forged Forging Turbine and Compressor Labyrinth Shaft Seals

Incoloy 903 Forged Forging Valve Balls,valve Bonnets,valve Body Bodies ,valve Stems,valve closures, valve seat rings, valve core, valve discs,for H type two way 2‐way one way back pressure valves, ball valve,check valve,gate valve

Alloy 903 Forged Forging Steel nuclear Power reactor coolant pumps Rotor Impellers

Incoloy ALloy 903 Forged Forgig Steel nuclear reactor coolant pump Casing Shells body bodis blocks,nuclear reactor coolant pumps containment seal chamber Rooms,nuclear reactor coolant pumps containment seal chamber Rooms

Incoloy ALloy 903 Forged Forging turbomachinery turbo centrifugal compressor Impeller,Compressor Shrouded Impellers

Incoloy ALloy 903 Forged Forging Steel PUMP Casing cover.PUMP BARREL,pump impeller,pump shafts, pump housing, pump shells,pump body,pump wear rings,pump case casing.

Alloy 903 Forged Forging Gas steam turbine disks, turbine impeller,turbine blisk,turbine discs,turbine wheel discs

Incoloy ALloy 903 Forging Steel Forging Forged Gas Steam Turbine Doubled-headed Double end Studs Fasteners Bolts bolting

Incoloy ALloy 903 Forging Steel gas steam Turbine Guide Rings,seal rings Labyrinth Rings Packing Seal Diaphragm & Seal Ring Rotor End Rings contours Casing Rings

Incoloy ALloy 903 Forged Forging Steel Gas Steam turbine diaphragm diapharagm nozzles

Incoloy 903 Forged Forging Gas Turbine LPT 1st & 2st 2nd Stg Stage Turbine Case Casings

Incoloy 903 Forged Forging Steel power plant steam turbine control reheat valve disc Disk

UNS N19903 Forged forging Gas Steam Turbine Valve Spindles/Stems/Rods,

Incoloy 903 Forging Steel Gas Steam Turbine MSV/GV/CV/CRV Valve Seats, Valve Cores, Valve Sleeves Spools,,Main Steam Valve Covers Bonnets Sleeves

Incoloy 903 forged forging steel pipes tubes shells piping tubing barrels housing, tube sheets,baffle plates, nozzles, channel flanges for boiler, heat exchanger,pressure vessel,reactors, heaters

Incoloy 903 is an agehardenable nickel-iron-cobalt alloy whose outstanding characteristics are a constant low coefficient of thermal expansion, a constant modulus of elasticity, and high strength.

Incoloy 903’s characteristics make it an excellent candidate for applications such as rocket-engine thrust chambers, steam-turbine bolts, springs, gage blocks, and ordnance hardware.

FOllowing is chemical compostion of Incoloy ALloy 903 forged rings

Nickel ..........................................................................36.0-40.0

Cobalt..........................................................................13.0-17.0

Aluminum ....................................................................0.30-1.15

Titanium.......................................................................1.00-1.85

Niobium.......................................................................2.40-3.50

Iron ...............................................................................Balance

Following is heat treament of alloy 903 forged parts

heat treated at 844°C (1550°F) for 1 hr. It is then quenched in water and aged at 719°C (1325°F) for 8 h followed by cooling. It is again aged at 622°C (1150°F) for 8 h followed by cooling in air.

Following of Incoloy 903 forging parts heat treatment nechanical property Delivery condition :

Tensile strength (precipitation hardened) 1310 MPa 190000 psi

Yield strength (@ strain 0.200 %, precipitation hardened) 1100 MPa 160000 psi

Elastic modulus (@ 0°C/32°F) 146.8 GPa 21290 ksi

Poisson's ratio (@ 250°C/482°F) 0.226 0.226

Elongation at break (precipitation hardened) 14% 14%

The following NDT inspections shall be performed after all heat treatments are performed

Visual inspection of all Incoloy 903 forging round bars

UT of all Incoloy 903 flat bars as per SEP 1923,inspection number D3 or D2 with dual (twin crystal search unit.100% of the volume shall be examined with the stipulated ecording level

Criteria stipulated in SEP 1923 quality class 2 b shall be applied with following modification:EE(single echo)and VE(numerous single echoes)without extension ≥2mm KSR are not permitted Defects above the recording limit shall be marked and it shall be ensured that these Incoloy 903 forging flat bars are not included in the lot delivered.

Following is inspection standard of Alloy 903 forged parts

ASTM A604 Standard test methods for macroetch testing of consumable electrode

remelted steel bars and billets

ASTM E112 Standard test methods for determining average grain size

EN ISO 6892-1:20 Metallic materials -Tensile testing -Part 1:Method of test at ambient temperature

ISO 204:2009 Metallic materials -Uniaxial creep testing in tension -Method of test

EN 10204 Metallic products -Types of inspection documents

EN ISO/IEC 17050:2004 Conformity assessment -Supplier's declaration of conformity -General requirements

All our Incoloy 903 forged material must give the material a required purity necessary for the application in following melting methods

one is triple melted material,VIM+ESR+VAR., the another one is double melted material,VIM+VAR.

All our UNS N19903 forging material shall be thoroughly worked,homogenous and free from blisters, cracks and injurious slag inclusions.

reported.

MARKING of our finished forged Incoloy 903 bars

Each part shall be stamped with:

The purchaser's part number

The purchaser's purchase number

The individual number

The heat number,if traceability to heat number is not possible by the individual number

The marking shall be surrounded by a frame or painted over with white durable paint.

Welcome your inquiry of Incoloy 903,UNS N19903,,Alloy 903,Incoloy ALloy 903) forging forged steel parts