Description

Jiangsu Liangyi professional manufacturer of Z10CNDA15-07 ,Z9CNDA15-07,Z9CNDA15.07,Z10CNDA15.07,Z10CNDA1507 ,Z9CNDA1507 open die forging parts and seamless rolled steel forged rings from china

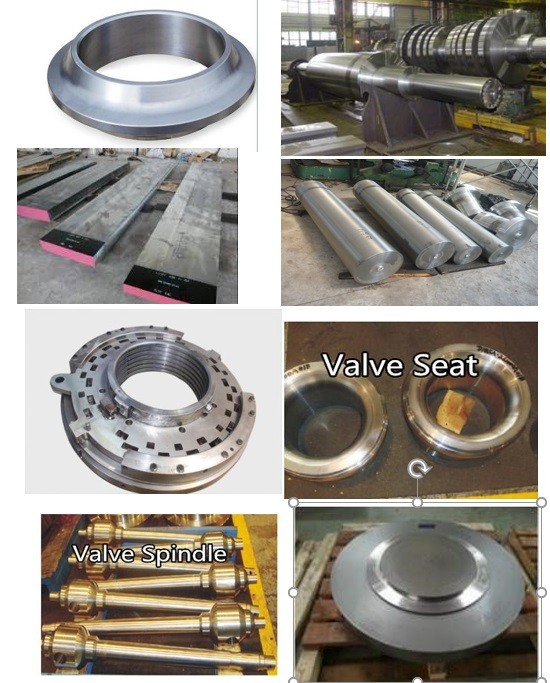

Following is the shape of Z10CNDA15-07 ,Z9CNDA15-07,Z9CNDA15.07,Z10CNDA15.07,Z10CNDA1507 ,Z9CNDA1507 forging steel material that we could do is:Z10CNDA15-07 Forged Steel round bars square bars Flat bars Rectangles Bars Rods,Z9CNDA15-07 Forged forging steel rings seamless rolled rings,Z9CNDA15.07 Forged Forging Steel Hubs housing shell Sleeves Bushes Bushing Cases Hollow Bars,Z10CNDA15.07 Forged Forging Steel Discs Disks Blocks plates,,Z9CNDA15.07 Forged Forging Steel Pipe Tubes Tubings Piping Shells Casings Case barrels Housings.

Following is forging products of Z10CNDA15-07 ,Z9CNDA15-07,Z9CNDA15.07,Z10CNDA1507 ,Z9CNDA1507 material that is used in following industry

Z10CNDA15-07 Forged Forging Gas Compressor Turbine Blades steel Flat Rectangles Bars

Z9CNDA15-07 Forged Forging Gas steam turbine disks, turbine impeller,turbine blisk,turbine discs

Z10CNDA15.07 Forging Steel Forging Forged Gas Steam Turbine Doubled-headed Double end Studs Fasteners Bolts

Z9CNDA1507 Forging Steel gas steam Turbine Guide Rings,seal rings Labyrinth Rings Packing Seal Diaphragm & Seal Ring Rotor End Rings contours Casing Rings

Z9CNDA15.07 forged forging steel pipes tubes shells piping tubing barrels housing, tube sheets, nozzles, channel flanges for boiler, heat exchanger,pressure vessel,reactors, heaters

Z10CNDA15-07 Forged Forging Valve Balls,valve Bonnets,valve Body Bodies ,valve Stems,valve closures, valve seat rings, valve core, valve discs,for H type two way 2‐way one way back pressure valves, ball valve,check valve,gate pump

Z10CNDA15-07 Forged Forging Steel nuclear Power reactor coolant pumps Rotor Impellers

Z9CNDA15.07 Forged Forging Marine Ship Boat Propeller Shafts

Z9CNDA15-07 Forged Forging downhole drilling tool Mud Motor Splined Drive shafts,Down hole Electric electrical submersible pumps ESP motor Splined Shaft

Z10CNDA15.07 Forged Forging Gas Air Compressor Rotor

Z9CNDA15-07 Forged Forgig Steel nuclear reactor coolant pump Casing Shells body bodis blocks,nuclear reactor coolant pumps containment seal chamber Rooms,nuclear reactor coolant pumps containment seal chamber Rooms

Z9CNDA1507 Forged Forging turbomachinery turbo centrifugal compressor Impeller,Compressor Shrouded Impellers

Z9CNDA15-07 Forged Forging Steel PUMP Casing cover.PUMP BARREL,pump impeller,pump shafts, pump housing, pump shells,pump body,pump wear rings

Z10CNDA15-07 ,Z9CNDA15-07 provides high strength and hardness, good corrosion resistance and minimum distortion on heat treatment. It is easily formed in the annealed condition and develops effective balance of properties by simple heat treatment. This alloy is useful for a wide range of applications that include retaining rings, springs, diaphragms, aircraft bulkheads, welded and brazed honeycomb paneling and other aircraft components requiring high strength at elevated temperatures.

FOllowing is chemical compostion of Z10CNDA15-07 ,Z9CNDA15-07 forged steel sleeves

C - 0.10

Si - 0.75

Mn - 1.20

P - 0.040

S - 0.015

Cr 14.00 16.00

Mo 2.00 3.00

Ni 6.50 7.75

Al 0.75 1.50

Following of Z10CNDA15-07 ,Z9CNDA15-07 forging parts mechnical property :

- Yield strength: Min 1000 N/mm2

- 0.2 % Yield strength: MIn 1100 N/mm2

- Elongation (5d): 15 %

For NDT test for all our Z10CNDA15-07 ,Z9CNDA15-07 forging parts, All Our NDT personnel are PCN and SNT-TC-1A qualified and certified in Non-Destructive Testing to level 2 or 3.All Our Level III and Level II industry certified NDT engineering team is trained inconventional and advanced techniques including radiography, ultrasonic, dye penetrant &magnetic particle to evaluate the material properties of a Z10CNDA15-07 ,Z9CNDA15-07 forging material without damage.

All our Z10CNDA15-07 ,Z9CNDA15-07 forging material will have following testing procedure

Visual inspections – Direct and Indirect

Magnetic particle

Dye penetrant – Visible and Fluorescent

Ultra-sonic testing

Radiograph

Metallurgical Testing

Macro & micro

Grain size determination

Charpy Impact testing

V notch Charpy

Hardness testing including micro and

macro Vickers tests

Tensile testing

Microscope imaging

All our Z10CNDA15-07 ,Z9CNDA15-07 forging patys can be release in 10204-3.2 certificate by following third party DNV-GL BUREAU VERITAS,LLOYD’S REGISTER,ABS, RINA,TÜV

Welcome your inquiry of Z10CNDA15-07 ,Z9CNDA15-07 forging forged steel parts

Following is the shape of Z10CNDA15-07 ,Z9CNDA15-07,Z9CNDA15.07,Z10CNDA15.07,Z10CNDA1507 ,Z9CNDA1507 forging steel material that we could do is:Z10CNDA15-07 Forged Steel round bars square bars Flat bars Rectangles Bars Rods,Z9CNDA15-07 Forged forging steel rings seamless rolled rings,Z9CNDA15.07 Forged Forging Steel Hubs housing shell Sleeves Bushes Bushing Cases Hollow Bars,Z10CNDA15.07 Forged Forging Steel Discs Disks Blocks plates,,Z9CNDA15.07 Forged Forging Steel Pipe Tubes Tubings Piping Shells Casings Case barrels Housings.

Following is forging products of Z10CNDA15-07 ,Z9CNDA15-07,Z9CNDA15.07,Z10CNDA1507 ,Z9CNDA1507 material that is used in following industry

Z10CNDA15-07 Forged Forging Gas Compressor Turbine Blades steel Flat Rectangles Bars

Z9CNDA15-07 Forged Forging Gas steam turbine disks, turbine impeller,turbine blisk,turbine discs

Z10CNDA15.07 Forging Steel Forging Forged Gas Steam Turbine Doubled-headed Double end Studs Fasteners Bolts

Z9CNDA1507 Forging Steel gas steam Turbine Guide Rings,seal rings Labyrinth Rings Packing Seal Diaphragm & Seal Ring Rotor End Rings contours Casing Rings

Z9CNDA15.07 forged forging steel pipes tubes shells piping tubing barrels housing, tube sheets, nozzles, channel flanges for boiler, heat exchanger,pressure vessel,reactors, heaters

Z10CNDA15-07 Forged Forging Valve Balls,valve Bonnets,valve Body Bodies ,valve Stems,valve closures, valve seat rings, valve core, valve discs,for H type two way 2‐way one way back pressure valves, ball valve,check valve,gate pump

Z10CNDA15-07 Forged Forging Steel nuclear Power reactor coolant pumps Rotor Impellers

Z9CNDA15.07 Forged Forging Marine Ship Boat Propeller Shafts

Z9CNDA15-07 Forged Forging downhole drilling tool Mud Motor Splined Drive shafts,Down hole Electric electrical submersible pumps ESP motor Splined Shaft

Z10CNDA15.07 Forged Forging Gas Air Compressor Rotor

Z9CNDA15-07 Forged Forgig Steel nuclear reactor coolant pump Casing Shells body bodis blocks,nuclear reactor coolant pumps containment seal chamber Rooms,nuclear reactor coolant pumps containment seal chamber Rooms

Z9CNDA1507 Forged Forging turbomachinery turbo centrifugal compressor Impeller,Compressor Shrouded Impellers

Z9CNDA15-07 Forged Forging Steel PUMP Casing cover.PUMP BARREL,pump impeller,pump shafts, pump housing, pump shells,pump body,pump wear rings

Z10CNDA15-07 ,Z9CNDA15-07 provides high strength and hardness, good corrosion resistance and minimum distortion on heat treatment. It is easily formed in the annealed condition and develops effective balance of properties by simple heat treatment. This alloy is useful for a wide range of applications that include retaining rings, springs, diaphragms, aircraft bulkheads, welded and brazed honeycomb paneling and other aircraft components requiring high strength at elevated temperatures.

FOllowing is chemical compostion of Z10CNDA15-07 ,Z9CNDA15-07 forged steel sleeves

C - 0.10

Si - 0.75

Mn - 1.20

P - 0.040

S - 0.015

Cr 14.00 16.00

Mo 2.00 3.00

Ni 6.50 7.75

Al 0.75 1.50

Following of Z10CNDA15-07 ,Z9CNDA15-07 forging parts mechnical property :

- Yield strength: Min 1000 N/mm2

- 0.2 % Yield strength: MIn 1100 N/mm2

- Elongation (5d): 15 %

For NDT test for all our Z10CNDA15-07 ,Z9CNDA15-07 forging parts, All Our NDT personnel are PCN and SNT-TC-1A qualified and certified in Non-Destructive Testing to level 2 or 3.All Our Level III and Level II industry certified NDT engineering team is trained inconventional and advanced techniques including radiography, ultrasonic, dye penetrant &magnetic particle to evaluate the material properties of a Z10CNDA15-07 ,Z9CNDA15-07 forging material without damage.

All our Z10CNDA15-07 ,Z9CNDA15-07 forging material will have following testing procedure

Visual inspections – Direct and Indirect

Magnetic particle

Dye penetrant – Visible and Fluorescent

Ultra-sonic testing

Radiograph

Metallurgical Testing

Macro & micro

Grain size determination

Charpy Impact testing

V notch Charpy

Hardness testing including micro and

macro Vickers tests

Tensile testing

Microscope imaging

All our Z10CNDA15-07 ,Z9CNDA15-07 forging patys can be release in 10204-3.2 certificate by following third party DNV-GL BUREAU VERITAS,LLOYD’S REGISTER,ABS, RINA,TÜV

Welcome your inquiry of Z10CNDA15-07 ,Z9CNDA15-07 forging forged steel parts