Description

Jiangsu Liangyi is professional manufacturer of Inconel 945,UNS N09945,,Alloy 945,Incoloy 945, Incoloy Alloy 945 open die forging parts and seamless rolled steel forged rings from china

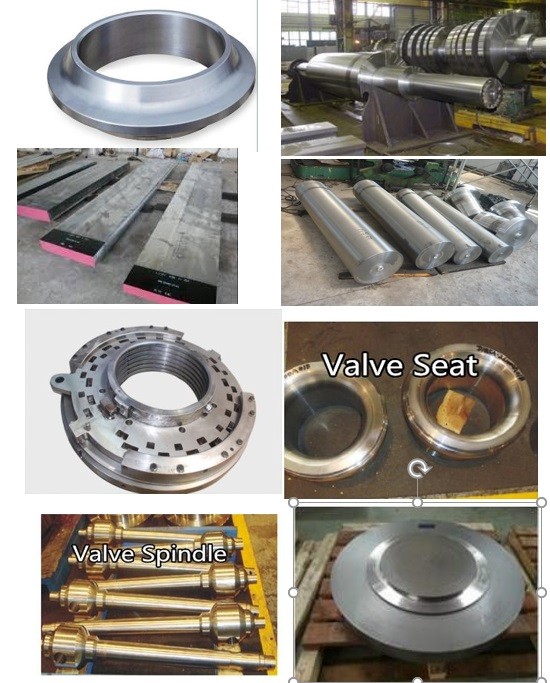

Following is the shape of Inconel 945,Incoloy 945, Alloy 945,UNS N09945 forging steel material that we could do is:Inconel 945 Forged Steel round bars square bars Flat bars Rectangles Bars Rods,Incoloy 945 Forged forging steel rings seamless rolled rings,Alloy 945 Forged Forging Steel Hubs housing shell Sleeves Bushes Bushing Cases Hollow Bars,UNS N09945 Forged Forging Steel Discs Disks Blocks plates,Inconel 945 Forged Forging Steel Pipe Tubes Tubings Piping Shells Casings Case barrels Housings.

Following is forging products of Inconel 945,Incoloy 945, Alloy 945,UNS N09945 material that is used in following industry

Alloy 945 forged forging gas separator protector intake HPS splined shaft

Incoloy 945 forging Forged Drilling Pipes Tubes Drill Rods drill Drilling collar

Incoloy 945 Forged/Forging Blow Out Blowout Preventer RAM Annular dual Bop Body Bodies Block

Alloy 945 Forged Forging drilling tools,risers,connectors,flexible joint ,seals,flanges gasket

Inconel 945 Forged Forging Valve Balls,valve Bonnets,valve Body Bodies ,valve Stems,valve closures, valve seat rings, valve core, valve discs,for H type two way 2‐way one way back pressure valves, ball valve,check valve,gate valve

Incoloy 945 Forged Forging Steel Butterfly Valve Main Shafts Spindles

Alloy 945 Forged Forging Swept branches outlets steel fittings swept saddles

Inconel 945 Forged Forging downhole drilling tool Mud Motor Splined Drive shafts,Down hole Electric electrical submersible pumps ESP motor Splined Shaft

Incoloy 945 Forged Forging Steels Christmas Trees wellhead Spool Body Bodies cylinder

Alloy 945 Forged Forging venturi cone meter Body Bodies Blocks

UNS N09945 Forged Forging Steel gate valves Body Bodies bespoke flat bars

Inconel 945 forged steel Flowseal cryogenic High Performance BV Butterfly Valves HPBV shaft

Inconel 945 forging steel Oil measurement valve Spool Ultrasonic flow meter bodies Body

Incoloy 945 Forged Forging Steel double studded adapter flange

Incoloy 945 Forged Forging Steel integral Mud Flange Flanged outlet Studded crosses

UNS N09945 Forged Forging Steel Casing Heads,Tubing Heads,Casing Hangers,Tubing Hangers,Tubing Spools,Casing Spools,Spacer Spools

Incoloy 945 Forged Forging Steel PUMP Casing cover.PUMP BARREL,pump impeller,pump shafts, pump housing, pump shells,pump body,pump wear rings,pump case casing.

Alloy 945 Forged Forging forge Steel transition Cones

Incoloy 945 forged foring marine ship shafts

Incoloy 945 is is a high-strength, corrosion-resistant alloy designed for demandingapplications in the oil and gas industry. The properties of this age hardenable nickel-iron-chromium alloy areenhanced by its contents of molybdenum, copper, niobium, titanium, and aluminum

Melting way of Incoloy 945 forged bars is as follows:

Alloy shall be multiple melted using consumable electrode practice in the remelt cycle or shall be induction melted under vacuum.If consumable electrode remelting is not performed in vacuum electrodes which have been produced by vacuum induction melting shall be used for remelting

All our Alloy 945 forging material shall be thoroughly worked,homogenous and free from blisters, cracks and injurious slag inclusions.

The minimum total hot forging reduction ratio of all our incoloy 945 round bars shall be 4:1.

FOllowing is chemical compostion of Incoloy 945 forged steel rings

Nickel ......…………………………………..…..45.0-55.0

Chromium ..…………………………………….19.5-23.0

Iron ……………….………………………………Balance

Molybdenum …….………………………………..3.0-4.0

Niobium .…………………………………………..2.5-4.5

Copper …………………………………………….1.5-3.0

Titanium ….………………………………………..0.5-2.5

Aluminum ….…………………………………….0.01-0.7

Manganese ...……………………………………1.0 max.

Silicon …..………………………………………..0.5 max.

Sulfur …..……………………………………….0.03 max.

Phosphorous .………………………………….0.03 max.

Carbon …..…………………………………0.005 to 0.04

FOllowing is heat treatment way of incoloy 945 forged material

Annealing - 1850ºF-1950ºF (1010ºC-1066ºC) for ½ to 4 hours, water quench.

Age Hardening - 1300ºF-1350ºF (704ºC-732ºC / 6-8 hours, furnace cool at 50ºF-100ºF (26ºC-56ºC) /hour to 1125ºF-1175ºF (607ºC-635ºC), hold at temperature for 6-8 hours, air cool

Mechanical properties of incoloy 945 forged hollow bars:

The mechanical testing shall be performed on the qualification on its QTC representing the heat and heat treatment lot in accordance with ASTM A370, ASTM E8 or ISO 6892-1.

Hardness testing shall be in accordance with:

— ISO 6506-1 or ASTM E10, or

— ISO 6508-1 or ASTM E18.

—ISO 6507-1 or ASTM E384 maybe used if ISO 6506-1 or ISO 6508-1 cannot be applied due to size, accessibility, or other limitations.

CVN impact testing shall be in accordance with ASTM E23 or any equivalent specification

U.T.S 150 KSI Min

0.2% Proof Stress 125 KSI Min

Elongation 18 %

NDE REQUIRMENT of all our incoloy 945 forged rings is as folowings

The acceptance criteria and inspection procedures of visual inspection, UT shall be as per API 6A, ASTM A388/388M and other relevant standards.

Ultrasonic Testing (UT) of inconel 945 forged hollow bars :

. Ultrasonic Inspection is required for all forgings after heat treatment for mechanical Properties exclusive of stress relief treatments or re-tempering to reduce hardness.

. UT examination methods shall be in accordance with ASTM A388/388M, ASTM E127 (ASTM E428) or ASTM E2375.

Calibration: The distance amplitude curve (DAC) shall be based on a maximum 1.6 mm (1/16

in.) flat-bottom hole (straight-beam technique) for metal thicknesses through 38.1 mm (1.1/2 in.), on a maximum 3.2 mm (1/8 in.) flat-bottom hole for metal thicknesses from 38.1 mm (1.1/2 in.)

through 152.4 mm (6 in.), and on a maximum 6.4 mm (1/4 in.) flat-bottom hole for metal thicknesses exceeding 152.4 mm (6 in.).

Welcome your inquiry of Inconel 945,Incoloy 945, Alloy 945,UNS N09945) forging forged steel parts