Description

Jiangsu Liangyi is professional manufacturer of 1.4606,X5NiCrTiMoVB25-15-2 ,X5NiCrTiMoVB25.15.2 ,X5NiCrTiMoVB25152 open die forging parts and seamless rolled steel forged rings from china

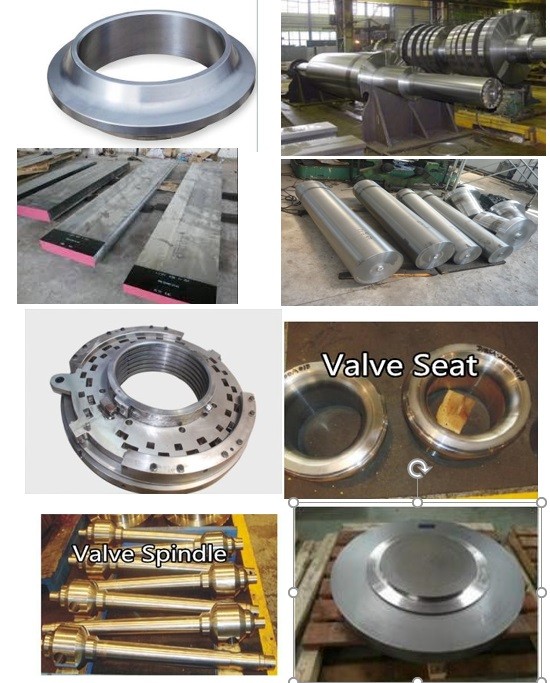

Following is the shape of 1.4606,X5NiCrTiMoVB25-15-2 ,X5NiCrTiMoVB25.15.2 ,X5NiCrTiMoVB25152 forging steel material that we could do is:1.4606 Forged Steel round bars square bars Flat bars Rectangles Bars Rods,1.4606 Forged forging steel rings seamless rolled rings,1.4606 Forged Forging Steel Hubs housing shell Sleeves Bushes Bushing Cases Hollow Bars,X5NiCrTiMoVB25-15-2 Forged Forging Steel Discs Disks Blocks plates,1.4606 Forged Forging Steel Pipe Tubes Tubings Piping Shells Casings Case barrels Housings.

Following is forging products of 1.4606,X5NiCrTiMoVB25-15-2 ,X5NiCrTiMoVB25.15.2 ,X5NiCrTiMoVB25152 material that is used in following industry

1.4606 Forged Forging Turbine and Compressor Labyrinth Shaft Seals

X5NiCrTiMoVB25-15-2 forged forging Railway locomotive Traction Motors Non-magnetic Forging Forged Retaining Rings factory

1.4606 forged forging Electromagnetic Stirring Rolls Rollers for continuous casting machine

1.4606 Forged Forging Valve Balls,valve Bonnets,valve Body Bodies ,valve Stems,valve closures, valve seat rings, valve core, valve discs,for H type two way 2‐way one way back pressure valves, ball valve,check valve,gate valve

1.4606 Forged Forging Steel nuclear Power reactor coolant pumps Rotor Impellers

1.4606 Forged Forging venturi cone meter Body Bodies Blocks

X5NiCrTiMoVB25-15-2 Forged Forging Steel gate valves Body Bodies bespoke flat bars

1.4606 forging steel Oil measurement valve Spool Ultrasonic flow meter bodies Body

1.4606 Forged Forging Steel double studded adapter flange

1.4606 Forged Forgig Steel nuclear reactor coolant pump Casing Shells body bodis blocks,nuclear reactor coolant pumps containment seal chamber Rooms,nuclear reactor coolant pumps containment seal chamber Rooms

1.4606 Forged Forging turbomachinery turbo centrifugal compressor Impeller,Compressor Shrouded Impellers

1.4606 Forged Forging Steel PUMP Casing cover.PUMP BARREL,pump impeller,pump shafts, pump housing, pump shells,pump body,pump wear rings,pump case casing.

1.4606 Forged Forging forge Steel transition Cone

X5NiCrTiMoVB25-15-2 Forged Forging Steel Pressure Vessel Reactor Nozzles

1.4606 Forged Forging Gas Compressor Turbine Blades steel Flat Rectangles Bars

1.4606 Forged Forging Gas steam turbine disks, turbine impeller,turbine blisk,turbine discs,turbine wheel discs

1.4606 Forging Steel Forging Forged Gas Steam Turbine Doubled-headed Double end Studs Fasteners Bolts bolting

1.4606 Forging Steel gas steam Turbine Guide Rings,Turbine shroud rings,seal rings Labyrinth Rings Packing Seal Diaphragm & Seal Ring Rotor End Rings contours Casing Rings

1.4606 Forged Forging Steel Gas Steam turbine diaphragm diapharagm nozzles

1.4606 Forged Forging Gas Turbine LPT 1st & 2st 2nd Stg Stage Turbine Case Casings

1.4606 Forged Forging Steel power plant steam turbine control reheat valve disc Disk

X5NiCrTiMoVB25-15-2 Forged forging Gas Steam Turbine Valve Spindles/Stems/Rods,

1.4606 Forging Steel Gas Steam Turbine MSV/GV/CV/CRV Valve Seats, Valve Cores, Valve Sleeves Spools,,Main Steam Valve Covers Bonnets Sleeves

1.4606 forged forging steel pipes tubes shells piping tubing barrels housing, tube sheets,baffle plates, nozzles, channel flanges for boiler, heat exchanger,pressure vessel,reactors, heaters

1.4606 is iron-based nickel chrome austenitic stainless alloy. This alloy maintains usefulness over a wide range of temperatures.

1.4606 is good for applications requiring high strength and corrosion resistance up to 1300°F (704°C). This alloy can be age hardened to a high strength level. The alloy is also used for low temperature applications requiring a ductile, non-magnetic, high strength material at range of temperatures.

FOllowing is production standard of 1.4606 forging parts

EN 10088-3: 2005 Stainless steels. Technical delivery conditions for semi-finished products, bars, rods, wire, sections and bright products of corrosion resisting steels for general purposes

EN 10088-1: 2005 Stainless steels. List of stainless steels

All our 1.4606 forged material must give the material a required purity necessary for the application in following melting methods one is triple melted material,VIM+ESR+VAR., the another one is double melted material,VIM+VAR.

Microstructure test of 1.4606 forged round bars

The microstructure must be uniform and free from extensive segregation and other inhomogeneity. Determination of grain size has to be performed according to EN ISO 643. Grain size checking of sheets shall be performed to the top and the bottom of a forged bars table

for each melt, thickness and heat treatment lot. Sheets shall achieve a mean grain size of 2-6. Grain size checking of bars shall be performed for each melt heat treatment lot. Bars shall achieve a grain size of 5 or coarser.

FOllowing is chemical compostion of 1.4606 forged parts

C max 0.08

Si max 1

Mn 1 - 2

Ni 24 - 27

P max 0.025

S max 0.015

Cr 13 - 16

Mo 1 - 1.5

Ti 1.9 - 2.3

Al max 0.35

B 0.001 - 0.01

Following of 1.4606 forging parts heat treatment nechanical property Delivery condition :

Rm - Tensile strength (MPa) (+AT) 700

Rm - Tensile strength (MPa) (+P880) 880-1150

Rp0.2 0.2% proof strength (MPa) (+AT) 250

Rp0.2 0.2% proof strength (MPa) +P880 550

KV - Impact energy (J) longitud., (+P) +20°

40

A - Min. elongation at fracture (%) (+AT) 35

A - Min. elongation at fracture (%) (+P880) 20

Brinell hardness (HB): (+AT) 212

Qualification of manufacturing procedure of 1.4606 forging parts

The Manufacturing Process Plan (MPP) shall be submitted to the approval of clients Material

& Process Engineering dept. clients before qualification procedure begins. It shall detail at least

the following:

• type of ingot (supplier, manufacturing process, dimensions, and tests to beperformed);

• forging process;

• heat treatment process;

• tests on component.

In general, dissection of the first piece within the terms detailed in the part specification is required.

This activity may be omitted, upon decision of clients, if the supplier has already proven to be able to successfully produce components of similar shape, dimensions and manufacturing

process.

Welcome your inquiry of 1.4606,X5NiCrTiMoVB25-15-2 ,X5NiCrTiMoVB25.15.2 ,X5NiCrTiMoVB25152, ) forging forged steel parts