Description

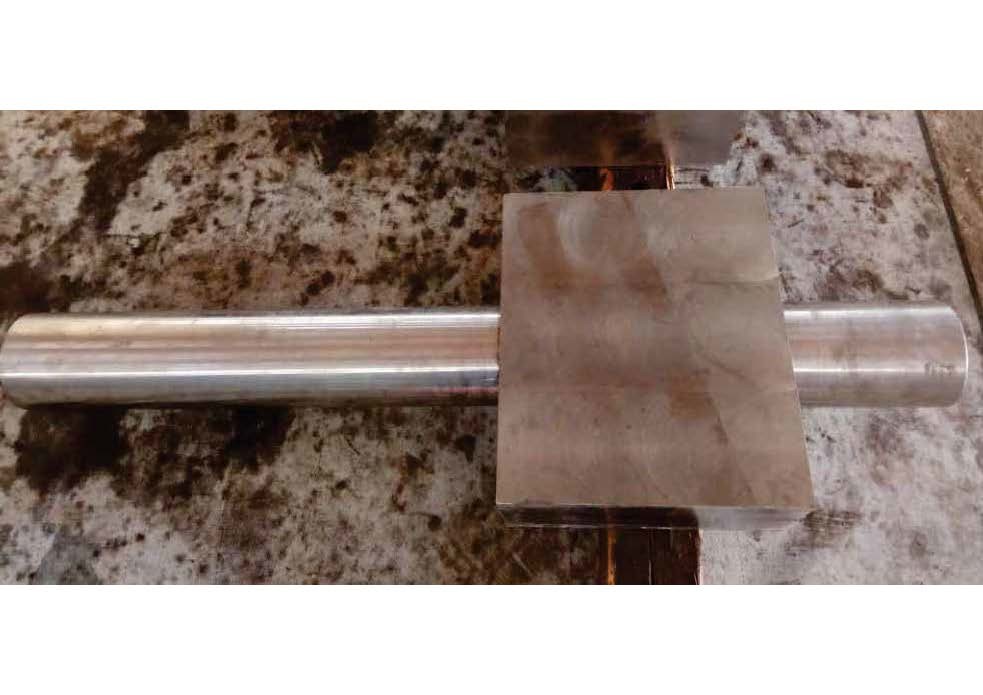

We are professional forged steel francis hydro power turbine hydraulic water turbine generator Wicked wicket gates, forging steel Hydro turbine Guide vane blades from china

The material grade of forging steel hydro turbine wicket gates that we could produce normall used in following grade

1.4313, X3CrNiMo13-4 forged steel hydraulic water turbine generator wicket gates

ASTM A743 CA-6NM CA6NM Hydro turbine Guide vane

GX4CrNi13-4, 1.4317, G-X5CrNi13-4 Forging Hydro turbine wicked gates

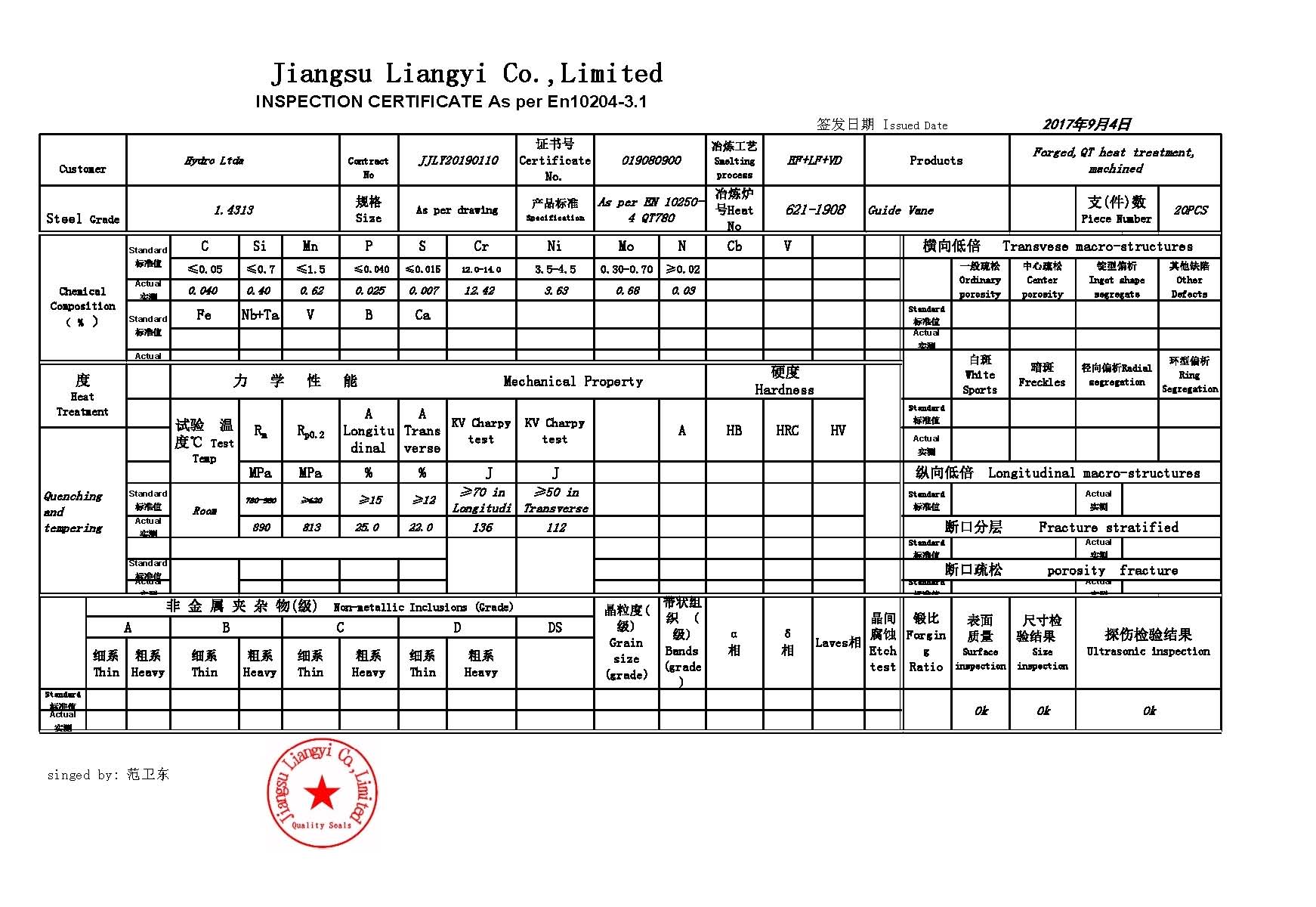

The melting methods of forged steel hydro turbine wicket gates is by EF+LF+VD

We could forged, heat treatment, rough machined forging hydraulic turbine wicketed gates, also we could final machined it as per clients drawing

To assure these all our forged steel hydro turbine wicket gates i , we offer you different testing methods in following

Testing machines

Universal testing machine 400 KN

Pendulum machine 450 Joules

Pendulum machine 750 Joules

Testing scope

Room-temperature tensile test

Creep test

Warm tensile test up to 1000 C°

Notch impact test from -196 C°

Bending test

Compression test

Drop-weight test (Pellini)

Hardness test (Brinell, Rockwell, Vickers)

Metallographic Testing

Microstructure examination / microsection test with grain size determination

Fiber orientation

Melting test

Purity level

Intermetallic phase

Huey-Test

Corrosion tests (G28, G48, IK)

Segregation testing on etched slices

Simulated heat treatment

Up to 1280 C°

Spectrometer for chemical element analysis

Optic emission spectrometer

X-ray fluorescence spectrometer

The following information is mandatory on the certified record of all our Forging Hydro turbine wicked gates

Purchase Order number and MISSION VG Specification number complete with revision letter.

Statement of the melting process used.

Chemical analysis and heat number.

Statement of heat treatment including time/temperature cycle, cooling media, and hardness of the forging and coupon separately.

Statement of actual values of the mechanical properties which wereobtained from the test coupon, as stipulated in paragraph 5.0.

The number of forgings or hot rolled bars submitted from each heat.

Liquid Penetrant or Magnetic Particle reports.

Ultrasonic Testing or Radiography reports.

Documentation in accordance with NACE MR0175/ISO15156 and EN 10204, Type 3.1.

Bellow is one material inspection of Forged steel Hydro turbine wicket gates in material of 1.4313