Description

Jiangsu Liangyi professional manufacturer of Monel K-500,Monel Alloy K500, Monel k500,ALloy K-500,UNS N05500 open die forging parts and seamless rolled steel forged rings from china

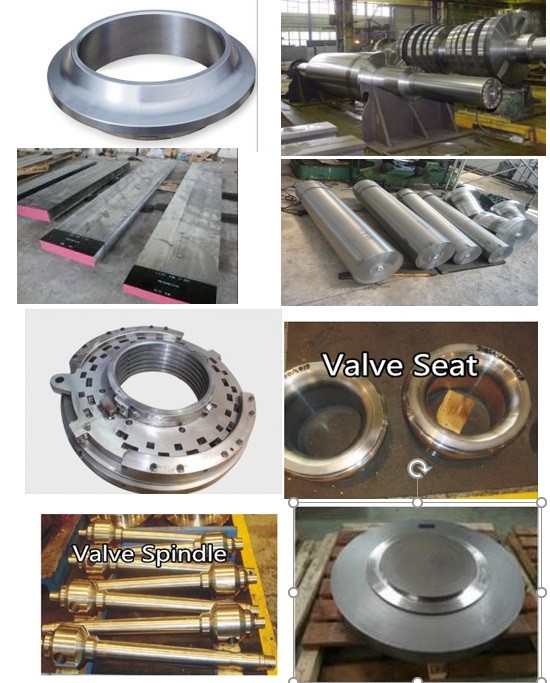

Following is the shape of Monel K-500,Monel Alloy K500, Monel k500,ALloy K-500,UNS N05500 forging steel material that we could do is:Monel K-500 Forged Steel round bars square bars Flat bars Rectangles Bars Rods,Monel Alloy K500 Forged forging steel rings seamless rolled rings,ALloy K-500 Forged Forging Steel Hubs housing shell Sleeves Bushes Bushing Cases Hollow Bars,UNS N05500 Forged Forging Steel Discs Disks Blocks plates,Monel K-500 Forged Forging Steel Pipe Tubes Tubings Piping Shells Casings Case barrels Housings.

Following is forging products of Monel K-500,Monel Alloy K500, Monel k500,ALloy K-500,UNS N05500material that is used in following industry

Monel K-500 forged forging steel pipes tubes shells piping tubing barrels housing, tube sheets,baffle plates, nozzles, channel flanges for boiler, heat exchanger,pressure vessel,reactors, heaters

Monel K500 forged forging oil well drill collars drill collars

Monel K500 forging steel high strength fasteners and bolting bolts

Monel K500 forged forging non-magnetic housings

Monel Alloy K500 Forged Forging Valve Balls,valve Bonnets,valve Body Bodies ,valve Stems,valve closures, valve seat rings,valve trim, valve core, valve discs,for H type two way 2‐way one way back pressure valves, ball valve,check valve,gate valve

ALloy K-500 Forged Forging Steel nuclear Power reactor coolant pumps Rotor Impellers

Monel K-500 forged steel Mechanical Seal Discs

Monel Alloy K500 Forged Forging Steel Butterfly Valve Main Shafts Spindles

UNS N05500 Forged Forging Marine Ship Boat Propeller Shafts

ALloy K-500 Forged Forging Swept branches outlets steel fittings swept saddles

Monel K-500 Forged Forging downhole drilling tool Mud Motor Splined Drive shafts,Down hole Electric electrical submersible pumps ESP motor Splined Shaft

Monel K-500 Forged Forging Gas Air Compressor Rotor

Monel Alloy K500 Forged Forging Steels Christmas Trees wellhead Spool Body Bodies cylinder

ALloy K-500 Forged Forging venturi cone meter Body Bodies Blocks

UNS N05500 Forged Forging Steel gate valves Body Bodies bespoke flat bars

Monel K-500 forging forged steel Couplings

Monel K-500 forged steel Flowseal cryogenic High Performance BV Butterfly Valves HPBV shaft

Monel K-500 forging steel Oil measurement valve Spool Ultrasonic flow meter bodies Body

Monel Alloy K500 Forged Forging Steel double studded adapter flange

Monel Alloy K500 Forged Forging Steel integral Mud Flange Flanged outlet Studded crosses

UNS N05500 Forged Forging Steel Casing Heads,Tubing Heads,Casing Hangers,Tubing Hangers,Tubing Spools,Casing Spools,Spacer Spools

Monel Alloy K500 Forged Forgig Steel nuclear reactor coolant pump Casing Shells body bodis blocks,nuclear reactor coolant pumps containment seal chamber Rooms,nuclear reactor coolant pumps containment seal chamber Rooms

Monel Alloy K500 Forged Forging turbomachinery turbo centrifugal compressor Impeller,Compressor Shrouded Impellers

Monel Alloy K500 Forged Forging Steel Forged Single Double Bossed boss Blanks FLANGED BOSSES

Monel Alloy K500 Forged Forging Steel PUMP Casing cover.PUMP BARREL,pump impeller,pump shafts, pump housing, pump shells,pump body,pump wear rings,pump case casing.

Alloy K-500 Forged Forging forge Steel transition Cone

UNS N05500 Forged Forging Steel Pressure Vessel Reactor Nozzles

Monel Alloy K500 is is a age-hardenable nickel-copper alloy that combines the corrosion resistance properties of alloy 400 with high strength corrosion fatigue and erosion resistance properties.

Monel K500 is precipitation hardenable through the additions of aluminum and titanium. The chemical composition of alloy K500 retains the excellent corrosion resistant characteristics of alloy 400. When compared with alloy 400, alloy K500 has enhanced strength and hardness after precipitation hardening. monel alloy K500 has approximately three times the yield strength and double the tensile strength of alloy 400.

Melting Practice Of UNS N05500 forged material

This alloy shall be produced by one of the following practices, unless further specified by clients:

Electric furnace under vacuum or protective atmosphere

Induction furnace under vacuum or protective atmosphere

Air induction meting + electroslag re-melting or ladle refining

Any supplementary re-melting is permitted.

Forging Practice Of monel K500 Forged parts

Forging or hot rolling shall be within the temperature range of 2100 to 1700 °F (1150 to 900°C)

and should be followed by a water quench from 1500°F min (800°C).

The chemical composition shall satisfy the following requirements, according to one of the following specifications:

AMS 4676

ASTM B865

QQ-N-286

ISO 9723

JIS 4553

The following limits of monel k500 forged parts include heat analysis tolerances.

| Element | (Symbol) | Percent | ||||||||

| Nickel + Cobalt | Ni | 63 | Min | |||||||

| Copper | Cu | 27 - 33 | Range | |||||||

| Iron | Fe | 2.0 | Max | |||||||

| Titanium | Ti | 0.35 - 0.85 | Range | |||||||

| Aluminum | Al | 2.30 - 3.15 | Range | |||||||

| Manganese | Mn | 1.5 | Max | |||||||

| Carbon | C | 0.18 | Max | |||||||

| Silicon | Si | 0.50 | Max | |||||||

| Zinc | Zn | 0.020 | Max | |||||||

| Phosphorus | P | 0.020 | Max | |||||||

| Sulphur | S | 0.015 | Max | |||||||

| Lead | Pb | 0.006 | Max | |||||||

| Tin | Sn | 0.006 | Max | |||||||

Heat Treatment of Monel Alloy K500 forged rings

Heat treatment times and temperatures indicated in this section are guidelines only. Material may be solution annealed and aged, or hot finished and aged. A number of different proprietary heat treatment schedules have been used successfully and are acceptable if the mechanical property requirements are met. In all cases, the heat treatment schedule shall be documented and available for audit.

All equipment used in heat-treating shall be maintained in good operating condition. All time temperature recorders shall be calibrated to standards traceable to National Standards, where they exist, or other acceptable standards.

Solution annealing is required for cold-worked material and is recommended for hot worked material. Solution annealing temperature should be 1800°F to 1900°F (980°C to 1040°C), for a minimum of 20 minutes/inch (1 minute/mm) of thickness, followed by water quenching.

Aging should be by one of the following cycles:

1080 to 1130°F (580 to 610°C), 4 to 16 hours, Furnace cool at approximately 20°F/hour (12°C/hour) to 900°F (480°C), air cool

1180°F +/-25°F (640°C +/-15°C) 2 hours, Furnace cool at approximately 28°F/hour (16°C/hour) to 900°F (480°C), air cool

Testing shall be performed per ASTM A370 or equivalent ISO Specification to meet the specific mechanical properties for the given age hardened condition.

| Property | Requirement | ISO Spec | ASTM | ||||||||||||

| Tensile Strength, ksi (MPa) Minimum … … … … … … … … | 140 (965) | ISO 6892 | A370 | ||||||||||||

| Yield Strength, ksi (MPa) Minimum … … … … … … … … … | 100 (690) | ISO 6892 | A370 | ||||||||||||

| Elongation in 4D, % Minimum … … … … … … … … … … … . | 17 | ISO 6892 | A370 | ||||||||||||

| Reduction of Area, % Minimum … … … … … … … … … … . | 25 | ISO 6892 | A370 | ||||||||||||

| Hardness HRc (BHN) Maximum … … … … … … … … … … . | 35 (315) | ISO 6506-1 | E18 | ||||||||||||

|

Charpy V-notch at -20°F (-29°C) or lower (Transverse direction for diameter >2.75in Longitudinal for diameters 0.6 to 2.75in, Notes 1,2) |

ISO 148 | A370 | |||||||||||||

| ISO 10423 | API 6A | ||||||||||||||

| Average energy, ft/lbs (J) Min, Note3 … … … . … … | 20 (27) | ||||||||||||||

| Single minimum energy, ft/lbs (J), Note3 … … … ... | 15 (20) | ||||||||||||||

|

Magnetic Permeability (max) @ Room Temperature, Note 4 … … … … … … … … … … … … … … … … … … … … … . |

1.01 | A342, Method 3 | |||||||||||||

Note 1: Longitudinal impact testing is acceptable for diameters > 2.75 in if the impact energy is greater

than 1.5 times the values specified for transverse. Impact testing is not required for diameter <0.6 in.

Note 2: Impact testing, or testing temperature, may be waived upon approval by Customer

Note 3: If sub size test specimens have to be used, the absorbed energy requirements shall be reduced as follows. Specimens smaller than 5mm thickness shall not be used.

| Specimen Size | Energy Requirements | ||||||||

|

10 x 10 mm 10 x 7.5 mm 10 x 5 mm |

E 5/6 E 2/3 E |

Note 4: Testing of Magnetic Permeability by Supplier not required

Material Quality of monel K500 FOrged parts

The material shall be homogenous in quality and free of injurious seams, laps or other defects, which are detrimental to the material quality, mechanical properties or machining process.

Welding by the supplying mill is prohibited.

Nondestructive Examination (NDE) Of monel k500 forged bars

"After all hot/cold working and final heat treatment the material shall be ultrasonically tested by a procedure

eqUivaIent to one of the foIIowing sPecifications, or at the sUPPIier,s choice. For 1-1/2” diameter and smaIIer,

ultrasonic testing is not required."

ASTM A388

specification NDE-31

EN 10308-quality Class 3.

Identification and Packing of finished Monel K500 forged bars

Protection shall be provided to prevent mechanical damage during shipment. Grade, heat number, heat treat condition shall be clearly marked on individual tube/forge lengths. Other information shall be provided or marked as required by purchase order.

Deviation from Requirements

All requests for deviation must be submitted to Customer for review and approval by the engineering department, or directly to the engineer in charge of the project.

Material complying with prior revisions of this specification and ordered from the mill within a 6 month period after the release date of this document shall be acceptable for the manufacture of parts referencing this document.

The supplier shall certify compliance with the quality requirements as stipulated on the purchase order in accordance with Customer procedure including a Statement of Compliance. The documentation shall include information as below, certification according to EN 10204, type 3.1B or equivalent.

Copy of the original mill certificate from the producing mill, which shall include the diameter.

Copy of actual chemical composition (heat analysis) of the material which lists all of the elements

specified in paragraph 3.4. Proper identification with heat number and heat treat lot required.

Copy of mechanical properties. Test results must meet the requirements

Statement of acceptance of Ultrasonic test per requirement

Statement of heat treatment path (Solution anneal and aged, or hot-work and aged

Results and methods of hardness testing as per this specification.

Statement of compliance from mill or supplier conforming compliance with this specification (by number) and the Customer Purchase order (by number and line item number).

All documentation generated by this specification shall be retained

Welcome your inquiry of Monel K-500,Monel Alloy K500, Monel k500,ALloy K-500,UNS N05500 forging forged steel parts