Description

Jiangsu Liangyi professional manufacturer of Z6CN13-04,Z 6 CN 13-04,Z6CN13.04,Z6CN1304 open die forging parts and seamless rolled steel forged rings from china

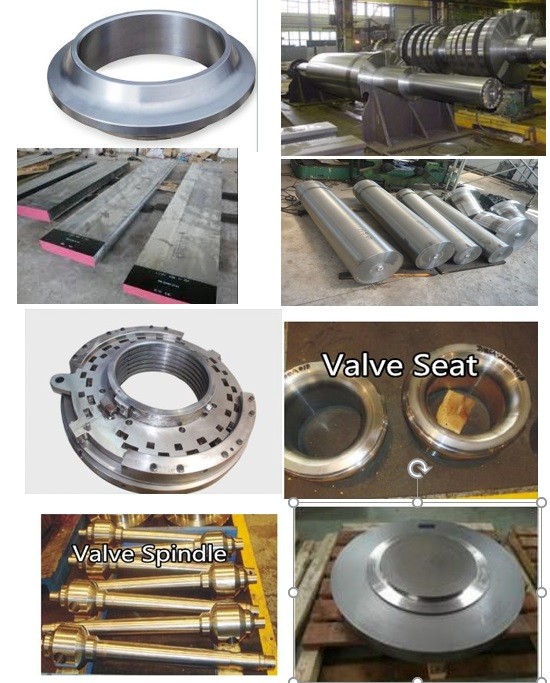

Following is the shape of Z6CN13-04 forging steel material that we could do is:Z6CN13-04 Forged Steel round bars square bars Flat bars Rectangles Bars Rods,Z6CN13-04,Forged forging steel rings seamless rolled rings,Z6CN13-04 Forged Forging Steel Hubs housing shell Sleeves Bushes Bushing Cases Hollow Bars,Z6CN13.04 Forged Forging Steel Discs Disks Blocks plates,Z6CN13-04 Forged Forging Steel Pipe Tubes Tubings Piping Shells Casings Case barrels Housings.

Following is forging products of Z6CN13-04,Z 6 CN 13-04,Z6CN13.04,Z6CN1304 material that is used in following industry

Z6CN13-04 Forged Forging Steel Francis Hydro Power Hydraulic Turbine Generator Wicked Wicket Gate, Guide Vanes

Z6CN1304 forged steel hydropower pelton bucket Forged Forging Flat Steel Bars

Z6CN13.04 Forged Forging Hydropower Francis Pelton Turbine runners,Turbine runners Discs Disks

Z6CN13-04 Forged Forged Pumps suction side sealing jacket seal chambers jacket casings

Z6CN13-04 Forged Forging Swivel Ring Flanges

Z6CN13-04 Forging/Forged Forge Steel Wye Piece/Piggable Wyes

Z6CN1304 Forged Forging Swept branches outlets steel fittings swept saddles

Z 6 CN 13-04 Forged Forging Steel double studded adapter flange

Z 6 CN 13-04 Forged Forging Steel Nuclear Power trunnions

Z6CN13-04 Forged Forging Gas Compressor Turbine Blades steel Flat Rectangles Bars

Z6CN13-04 Forged Forging Gas steam turbine disks, turbine impeller,turbine blisk,turbine discs

Z6CN13-04 Forging Steel Forging Forged Gas Steam Turbine Doubled-headed Double end Studs Fasteners Bolts

Z 6 CN 13-04 Forging Steel gas steam Turbine Guide Rings,seal rings Labyrinth Rings Packing Seal Diaphragm & Seal Ring Rotor End Rings contours Casing Rings

Z6CN13-04 forged forging steel pipes tubes shells piping tubing barrels housing, tube sheets, nozzles, channel flanges for boiler, heat exchanger,pressure vessel,reactors, heaters

Z6CN13-04 Forged Forging Valve Balls,valve Bonnets,valve Body Bodies ,valve Stems,valve closures, valve seat rings, valve core, valve discs,for H type two way 2‐way one way back pressure valves, ball valve,check valve,gate pump

Z6CN13-04 Forged Forging Steel nuclear Power reactor coolant pumps Rotor Impellers

Z6CN13-04 Forged Forging Block Adaptor

Z6CN13-04 Forged Forging venturi cone meter Body Bodies Blocks

Z6CN13-04 Forged Forgig Steel nuclear reactor coolant pump Casing Shells body bodis blocks,nuclear reactor coolant pumps containment seal chamber Rooms,nuclear reactor coolant pumps containment seal chamber Rooms

Z6CN13-04 Forged Forging turbomachinery turbo centrifugal compressor Impeller,

Z6CN13-04 Forged Forging Steel PUMP Casing cover.PUMP BARREL,pump impeller,pump shafts, pump housing, pump shells,pump body,pump wear rings

Z6CN13-04 is corrosion resistant, softmartensitic chrome-nickel steel with molybdenum addtion.Very good strength and toughness properties,The material Z6CN13-04 impresses with its very good mechanical properties. Has good toughness properties in the tempered state. Z6CN13-04 can be used in the temperature range from -60 ° C to 300 ° C. The material Z6CN13-04 also has a medium corrosion resistance and machinability, as well as poor weldability and ist easy to polish. Z6CN13-04 can be welded using arc welding.

Due to its good mechanical properties, 1Z6CN13-04is used in the chemical and petrochemical industries, plant engineering, the pump industry and turbine wheels. Z6CN13-04 is also used in power engineering and in valve construction,, waves, valves, vanes, pump covers and pump housings.

Macrostructure of Z6CN13-04,Z 6 CN 13-04,Z6CN13.04,Z6CN1304forging steel [arts is as follow

Visual examination of transverse full cross-sections from Z6CN13-04 forged bars, billets, and stock for Z6CN13-04 forging, Z6CN13-04 forged rings, orextrusions, etched in hot hydrochloric acid in accordance with ASTM A 604, shall show no pipe or cracks. Porosity,segregation, inclusions, and other imperfections shall be no worse than the macrographs of ASTM A 604

- MACROSTRUCTURE LIMITS of Z6CN13-04 forging materialis as follow

Class Condition Severity

1 Freckles A

2 White Spots A

3 Radial Segregation A

4 Ring Pattern B

FOllowing is chemical compostion of Z6CN13-04,Z 6 CN 13-04,Z6CN13.04,Z6CN1304 forged steel pipes

Carbon (C%) ≤ 0,05

Manganese (Mn%) ≤ 1,50

Silicon (Si%) ≤ 0,70

Phosphorus (P%) ≤ 0,04

Sulfur (S%)≤ 0,015

Chrome (Cr%) Min: 12,0 Max: 14,0

Nickel (Ni%) Min: 3,50 Max: 4,50

Molybdenum (Mo%) Min: 0,30 Max: 0,70

Nitrogen (N%)≥0,020

Following of Z6CN13-04 forging parts mechnical property :

Rm – Tensile strength (MPa) (+A) 1100

Rm – Tensile strength (MPa) (+QT650) 700-800

Rm – Tensile strength (MPa) (+QT780) 780-980

Rm – Tensile strength (MPa) (+QT900) 900-1100

Rp0.2 0.2% proof strength (MPa) (+QT650) 520

Rp0.2 0.2% proof strength (MPa) (+QT780) 620

Rp0.2 0.2% proof strength (MPa) (+QT900) 800

FOllowing is testing standard of our Z6CN13-04 forged steel turbine blade flat bats

ASTM E10-12: Standard Test Method for Brinell hardness of Metallic Materials;

ASTM A370-12: Standard Test Methods and Definitions for Mechanical Testing of Steel Products;

ASTM E23-07a: Standard Test Methods for Notched Bar Impact Testing of Metallic Materials;

AMS 2315G: Determination of Delta Ferrite Content,

ASTM E45-05: Standard Test Methods for Determining the Inclusion Content of Steel,

ASTM E112-10: Standard Test Methods for Determining Average Grain Size,

ASTM E837: Standard Test Method for Determining Residual Stresses by the Hole-Drilling Strain-Gage Method,

Welcome your inquiry of Z6CN13-04,Z 6 CN 13-04,Z6CN13.04,Z6CN1304 forging forged steel parts