Description

Jiangsu Liangyi professional manufacturer of 1.6946,30CrMoNiV5-11,30CrMoNiV511,30CrMoNiV5.11,30 CrMoNiV 5 11 open die forging parts and forged steel gas steam turbine generator rotor shafts ,,turbo generator,Turbomachines,Turbomachinery,turbogenerator forging steel shafts factory from china

1.6946,30CrMoNiV5-11 is Creep resisting steel, hardened and tempered as per standard of SEW 555 (1984) Steels for larger forgings for components in turbine and generator production, such as turbine bolts, turbine rotor shafts, turbine blades and so on

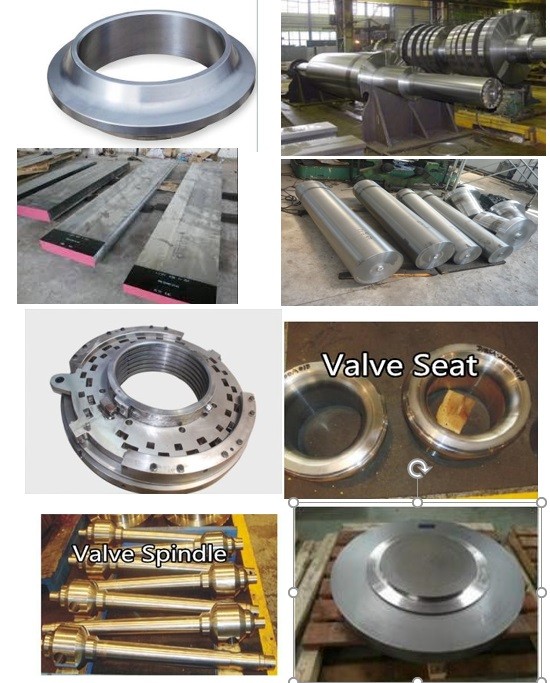

Following is the shape of 1.6946,30CrMoNiV5-11,30CrMoNiV511,30CrMoNiV5.11,30 CrMoNiV 5 11 forging steel material that we could do is:30CrMoNiV5-11 Forged Steel round bars square bars Flat bars Rectangles Bars Rods,30 CrMoNiV 5 11 Forged forging steel rings seamless rolled rings, 30CrMoNiV5.11 Forged Forging Steel Hubs housing shell Sleeves Bushes Bushing Cases Hollow Bars,30CrMoNiV511 Forged Forging Steel Discs Disks Blocks plates, 1.6946 Forged Forging Steel Pipe Tubes Tubings Piping Shells Casings Case barrels Housings.30CrMoNiV5-11 Forged Forging Steel Gas Steam Turbine Rotors Shafts,1.6946 Forged Forging Gas Compressor Turbine Blades turbine Vane steel Flat Rectangles Bars,30CrMoNiV511 Forged Forging Steel gas steam Turbine Guide Rings,seal rings Labyrinth Rings Packing Seal Diaphragm & Seal Ring Rotor End Rings contours Casing Rings,,30CrMoNiV5.11 Forged forging Gas Steam Turbine Valve Spindles/Stems/Rods,30CrMoNiV5-11 Forging Forged Gas Steam Turbine Doubled-headed Double end Studs Fasteners Bolts

Carbon (C%): 0,28 Max: 0,34

Manganese (Mn%) : 0,30 Max: 0,80

Silicon (Si%) :≤ 0,15

Phosphorus (P%):≤ 0,01

Sulfur (S%):≤ 0,007

Chrome (Cr%):Min: 1,10 Max: 1,40

Nickel (Ni%):Min: 0,50 Max: 0,75

Molybdenum (Mo%):Min: 1,00 Max: 1,20

Aluminum (Al%):≤ 0,010

Vanadium (V%): 0,25 Max: 0,35

The mechanical property of 30CrMoNiV5-11 forged steel steam turbine rotor material is as followings

Elongation, transverse test at 20.0 °C minimum 12 %

Reduction of area, transverse at 20.0 °C minimum 40 %

Tensile strength, transverse at 20.0 °C 700 - 850 MPa

Yield strength Rp0.2, transverse at 20.0 °C 550 MPa

Yield strength Rp0.2 at 100.0 °C 525 MPa

Yield strength Rp0.2 at 200.0 °C 500 MPa

Yield strength Rp0.2 at 250.0 °C 480 MPa

Yield strength Rp0.2 at 300.0 °C 465 MPa

Yield strength Rp0.2 at 350.0 °C 445 MPa

Yield strength Rp0.2 at 400.0 °C 425 MPa

Yield strength Rp0.2 at 450.0 °C 400 MPa

Yield strength Rp0.2 at 500.0 °C 365 MPa

All our 30CrMoNiV5.11 forged turbine material will be in following test

Tangential Tensile Strength Test for every pieces of 30CrMoNiV5.11 forged turbine rotor shafts

Tangential Notched bar Impact Test for every pieces of 30CrMoNiV5.11 forged turbine blade steel

Axial Core Tensile Strength Test for every pieces of 30CrMoNiV5.11 forged turbine generator rotor shafts

Axial Core Notched bar Impact Test for every pieces of 30 CrMoNiV 5 11 forged gas steam turbine rotor shafts

Radial Core Tensile Strength Test for every pieces of 1.6946 forged turbine rotor shafts

Radial Core Notched bar Impact Test for every pieces of 30CrMoNiV5.11 forged turbine rotor shafts

UT Examination for every pieces of 30CrMoNiV5.11 forged turbine Gas Steam Turbine Valve Spindles/Stems/Rods

Boroscope Examination and MT Test for every pieces of 30CrMoNiV5.11 forged turbine rotor shafts

Visual and Dimensional for every pieces of 30CrMoNiV5.11 forged turbine rotor shafts

Measurement of Magnetic Induction for every pieces of 30CrMoNiV5.11 forged turbine rotor shafts

Marking for every pieces of 30CrMoNiV511 forged turbine Gas Steam Turbine Doubled-headed Double end Studs Fasteners Bolts

Measurement of Residual Stress for every pieces of 30CrMoNiV5-11 forged turbine rotor shafts

Checking for Completeness of QA-Documents for every pieces of 30CrMoNiV5.11 forged turbine rotor shafts

All our 30CrMoNiV5.11 forging steel gas turbine rotor shafts can be inspected by by TÜV, DNV-GL, ABS, LR,. BV amd release Inspection certificate EN 10204-3.2

Welcome your inquiry of 1.6946,30CrMoNiV5-11,30CrMoNiV511,30CrMoNiV5.11,30 CrMoNiV 5 11 forging forged steel parts