Description

Jiangsu Liangyi professional manufacturer of 1.6963,27NiCrMoV16-7,27NiCrMoV16.7, 27NiCrMoV167 open die forging parts and forged steel gas steam turbine turbine rotor shafts from china

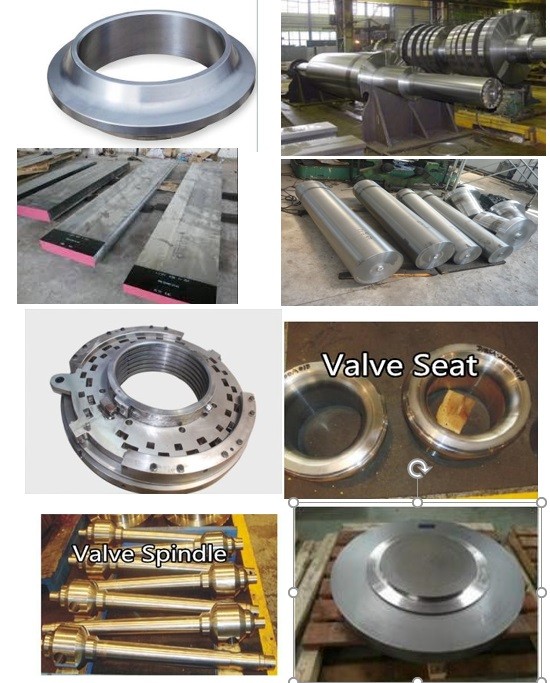

Following is the shape of 1.6963,27NiCrMoV16-7,27NiCrMoV16.7, 27NiCrMoV167 Forging steel material that we could do is:27NiCrMoV16-7 Forged Steel round bars square bars Flat bars Rectangles Bars Rods, 27NiCrMoV16.7 Forged forging steel rings seamless rolled rings, 27NiCrMoV167 Forged Forging Steel Hubs housing shell Sleeves Bushes Bushing Cases Hollow Bars,1.6963 Forged Forging Steel Discs Disks Blocks plates, 27NiCrMoV167 Forged Forging Steel Pipe Tubes Tubings Piping Shells Casings Case barrels Housings. 27NiCrMoV167 Forged Forging Steel Gas Steam Turbine Rotors Shafts,27NiCrMoV16-7 Forged Forging Gas Compressor Turbine Blades turbine Vane steel Flat Rectangles Bars, 27NiCrMoV16.7 Forged Forging Steel gas steam Turbine Guide Rings,seal rings Labyrinth Rings Packing Seal Diaphragm & Seal Ring Rotor End Rings contours Casing Rings,,27NiCrMoV16.7 Forged forging Gas Steam Turbine Valve Spindles/Stems/Rods,27NiCrMoV167 Forging Forged Gas Steam Turbine Doubled-headed Double end Studs Fasteners Bolts

Our 1.6963,27NiCrMoV16-7,27NiCrMoV16.7, 27NiCrMoV167 forged steel parts is normal melting by Basic Electric Furnace (EAF, AOD, VOD) or + Electroslag remelting. (ESR) AS PER CLIENTS NEEDS

Chemical composition for 1.6963,27NiCrMoV16-7 forged steel gas turbine rotor shafts as follows

Carbon (C%) Min: 0,22 Max: 0,32

Manganese (Mn%) ≤ 0,06

Silicon (Si%) ≤ 0,06

Phosphorus (P%) ≤0,004

Sulfur (S%) ≤0,003

Chrome (Cr%) Min: 1,50 Max: 2,00

Nickel (Ni%) Min: 3.8 Max: 4.0

Molybdenum (Mo%) Min: 0,40 Max: 0,60

Vanadium (V%) Min: 0,05 Max: 0,15

The following properties of 27NiCrMoV16-7 forging turbine blade flat bars at room temperature must be demonstrated by the following tests

Tensile strength, Rm: 850- 1000MPa

The yield point, Rp0,2: >700 MPa Properties of samples tested

longitudinally: Elongation, A:> 15%

Reduction > 40%

Charpy test :minimum 80J

27NiCrMoV16-7 forging steel turbine parts at elevated temperatures - the yield strength is as follows

Temperature 200℃ - Rp0,2: >625 MPa

Temperature 250℃ - Rp0,2: >600 MPa

Temperature 300℃ - Rp0,2: >580 MPa

Temperature 350℃ - Rp0,2: >550 MPa

Temperature 400℃ - Rp0,2: >510 MPa

Temperature 450℃ - Rp0,2: >480 MPa

Temperature 500℃ - Rp0,2: >400 MPa

We could produce forged steel 27NiCrMoV16-7 turbine rotor shafts in High,middle,low press steam turbine rotor,generator rotor, 35MW,50WM,60WM,70WM steam turbine rotor;

Our 27NiCrMoV16.7 forged turbine rotor shafts is qualified in certificate of ISO 9001,ISO 14001.ISO 50001,ISO 3834-2, ISO 9712,ISO/IEC 17025,NORSOK M122,NORSOK M123

All our 27NiCrMoV16-7 forged steel turbine parts can be release in 10204-3.2 certificate by following third party DNV-GL BUREAU VERITAS,LLOYD’S REGISTER,ABS, RINA,TÜV

For melting 27NiCrMoV167 forging steel material, we have following melting equipment

60 t Electric Arc Furnace (EAF) / Power 40 MVA

2 Ladle Furnace (LF)

2 Tank Degassing VD - VOD type

Pits for bottom pouring

ESR Plant (max weight 32 t)

In order to make forging and make heat treatment 27NiCrMoV16.7 forging turbine rotor shafts, we have following production equipment

Forging Process:3200/4200/6000 t Open die presses

Manipulators, Lifting Capacity up to 60 t

Heating Forging Furnaces, Max Capacity 150 t

Furnaces for Hydrogen Bake-Out Up to 14 m

Heat Treatment Semi-automatic Heat Treatment System Quality Heat Treatment

Furnaces Max lenght 18 m Quenching tanks up to 16 m

Also we have following machining equipment of rough machined 27NiCrMoV16-7 forged steel turbine rotor shafts

Rough & Finishing Machining, Vertical Lathes,Parallel Lathes,Extra Large Parallel Lathes, NC Boring Machines, Milling, Planning Machine, Column Drill

The quality of Jiangsu products 27NiCrMoV16-7 forging workshop is based on its “state-of-the-art”technology of its laboratories for metallurgy and chemistry. we perform

a range of tests, including mechanical property tests, chemical and environmental analyses, metallographic, macrographic and micrographic tests using optical and electronic microscopes.

, all 1.6963 forging steel turbine rotor shafts materials are tested and certified in accordance with nternational standards and Customer’s specifications, using any combination of the following methods: UT-RT-HT-PT-MT-VT-DT