Description

Jiangsu Liangyi is professional manufacturer of AMS 5940 open die forging parts and seamless rolled steel forged rings from china

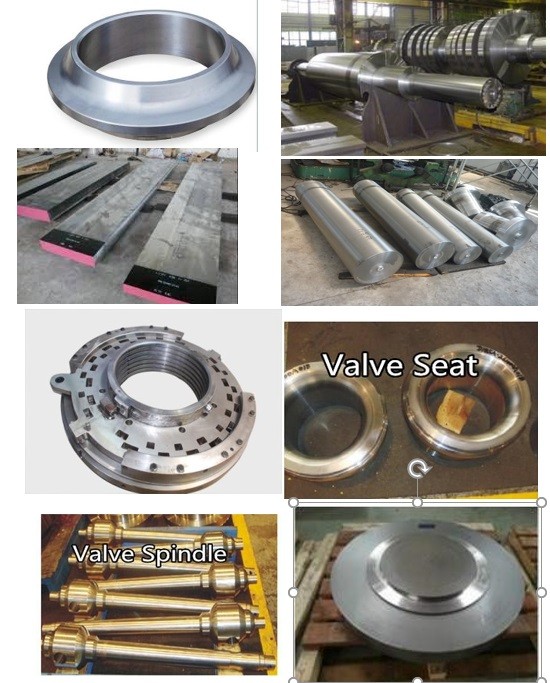

Following is the shape of AMS 5940 forging steel material that we could do is:AMS 5940 Forged Steel round bars square bars Flat bars Rectangles Bars Rods,AMS 5940 Forged forging steel rings seamless rolled rings,AMS 5940 Forged Forging Steel Hubs housing shell Sleeves Bushes Bushing Cases Hollow Bars,AMS 5940 Forged Forging Steel Discs Disks Blocks plates,AMS 5940 Forged Forging Steel Pipe Tubes Tubings Piping Shells Casings Case barrels Housings.

Following is forging products of AMS 5940 material that is used in following industry

AMS 5940 Forged Forging Valve Balls,valve Bonnets,valve Body Bodies ,valve Stems,valve closures, valve seat rings, valve core, valve discs,for H type two way 2‐way one way back pressure valves, ball valve,check valve,gate valve

AMS 5940 Forged Forging turbomachinery turbo centrifugal compressor Impeller,Compressor Shrouded Impellers

AMS 5940 Forged Forging Steel PUMP Casing cover.PUMP BARREL,pump impeller,pump shafts, pump housing, pump shells,pump body,pump wear rings,pump case casing.

AMS 5940 Forged Forging forge Steel transition Cone

AMS 5940 Forged Forging Steel Pressure Vessel Reactor Nozzles

AMS 5940 Forged Forging Gas Compressor Turbine Blades steel Flat Rectangles Bars

AMS 5940 Forged Forging Gas steam turbine disks, turbine impeller,turbine blisk,turbine discs,turbine wheel discs

AMS 5940 Forging Steel Forging Forged Gas Steam Turbine Doubled-headed Double end Studs Fasteners Bolts bolting

AMS 5940 Forging Steel gas steam Turbine Guide Rings,seal rings Labyrinth Rings Packing Seal Diaphragm & Seal Ring Rotor End Rings contours Casing Rings

AMS 5940 Forged Forging Steel Gas Steam turbine diaphragm diapharagm nozzles

AMS 5940 Forged Forging Gas Turbine LPT 1st & 2st 2nd Stg Stage Turbine Case Casings

AMS 5940 Forged Forging Steel power plant steam turbine control reheat valve disc Disk

AMS 5940 Forged forging Gas Steam Turbine Valve Spindles/Stems/Rods,

AMS 5940 Forging Steel Gas Steam Turbine MSV/GV/CV/CRV Valve Seats, Valve Cores, Valve Sleeves Spools,,Main Steam Valve Covers Bonnets Sleeves

AMS 5940 forged forging steel pipes tubes shells piping tubing barrels housing, tube sheets,baffle plates, nozzles, channel flanges for boiler, heat

AMS 5940 is an oxidation-resistant low coefficient of thermal expansion (low CTE) superalloy developed for gas turbine applications.

AMS 5940 is strengthened by a precipitation-hardening heat treatment made possible by additions of niobium and aluminum.

In addition, the aluminum content provides excellent resistance to oxidation at high temperatures.The combination of low expansion, high strength and excellent resistance to oxidation makes the alloy especially useful for gas turbine and steam turbine components.

AMS 5940 forged material shall be multiple melted using consumable electrode practice in the remelt cycle. If consumable electrode remeltingis not performed in vacuum, electrodes which have been produced by vacuum induction melting shall be used for remelting."

Check Analysis of AMS 5940 forged parts Composition variations shall meet the applicable requirements of AMS 2269.

AMS 5940 forged parts Shall conform to the percentages by weight shown in Table 1, determined by wet chemical methods in accordance with ASTM E 354, by spectrochemical methods, or by other analytical methods acceptable to purchaser.

Room temperature of AMS 5940 forged parts mechnical property

1200 °F (649 °C) mechanical property test is as following

Tensile Strength 130 ksi (896 MPa)

Yield Strength at 0.2% Offset 90 ksi (621 MPa)

Elongation in 4D 15%

Reduction of Area 25%

Grain flow of AMS 5904 forgings, except in areas which contain flash-line end grain, shall follow the general contour of the forgings showing no evidence of reentrant grain flow.

Tests for AMS 5904 forging material the following requirements are acceptance tests and shall be performed on each heat or lot as applicable:

Composition and mean coefficient of linear expansion of each heat.

Hardness and average grain size of each lot of bars, forgings, and flash welded rings as solution heat treated.

Room-temperature tensile properties , hardness , and stress-rupture properties of each lot of bars, forgings, and flash welded rings after precipitation heat treatment.

Tolerances of AMS 5904 bars.

Periodic Tests

Tests for the following requirements are periodic tests and shall be performed at a frequency selected by the vendor

unless frequency of testing is specified by purchaser:

Tensile properties at 1200 °F (649 °C) of AMS 5904 forged parts after precipitation heat treatment.

Grain flow of AMS 5904 forging

FOllowing is inspection standard of AMS 5940 forged parts:

ASTM E 8/E 8M Tension Testing of Metallic Materials

ASTM E 18 Rockwell Hardness of Metallic Materials

ASTM E 21 Elevated Temperature Tension Tests of Metallic Materials

ASTM E 112 Determining Average Grain Size

ASTM E 139 Conducting Creep, Creep-Rupture, and Stress-Rupture Tests of Metallic Materials

ASTM E 228 Linear Thermal Expansion of Solid Materials with a Pushrod Dilatometer

ASTM E 292 Conducting Time-for-Rupture Notch Tension Tests of Materials

ASTM E 354 "Chemical Analysis of High-Temperature, Electrical, Magnetic, and Other Similar Iron, Nickel, and Cobalt

Alloys"

ASTM E 1181 Characterizing Duplex Grain Sizes

AMS 5904 each forged parts shall furnish with each shipment a report showing the vendor’s name and the country where the metal was melted (e.g., final melt in the case of metal processed by multiple melting operations) and the results of tests for composition and mean coefficient of linear expansion of each heat, and for hardness and average grain size for each lot of AMS 5904 forged parts solution treated, and for hardness, room temperature tensile properties and stress rupture properties of each lot of AMS 5904 forged parts after precipitation heat treatment, and stating that the product conforms to the other technical requirements. This report shall include the purchase order number, heat and lot numbers, AMS5940D, size, and quantity. If forgings are supplied, the size and melt source of stock used to make the forgings shall also be included."

Welcome your inquiry of AMS 5940) forging forged steel parts

Following is the shape of AMS 5940 forging steel material that we could do is:AMS 5940 Forged Steel round bars square bars Flat bars Rectangles Bars Rods,AMS 5940 Forged forging steel rings seamless rolled rings,AMS 5940 Forged Forging Steel Hubs housing shell Sleeves Bushes Bushing Cases Hollow Bars,AMS 5940 Forged Forging Steel Discs Disks Blocks plates,AMS 5940 Forged Forging Steel Pipe Tubes Tubings Piping Shells Casings Case barrels Housings.

Following is forging products of AMS 5940 material that is used in following industry

AMS 5940 Forged Forging Valve Balls,valve Bonnets,valve Body Bodies ,valve Stems,valve closures, valve seat rings, valve core, valve discs,for H type two way 2‐way one way back pressure valves, ball valve,check valve,gate valve

AMS 5940 Forged Forging turbomachinery turbo centrifugal compressor Impeller,Compressor Shrouded Impellers

AMS 5940 Forged Forging Steel PUMP Casing cover.PUMP BARREL,pump impeller,pump shafts, pump housing, pump shells,pump body,pump wear rings,pump case casing.

AMS 5940 Forged Forging forge Steel transition Cone

AMS 5940 Forged Forging Steel Pressure Vessel Reactor Nozzles

AMS 5940 Forged Forging Gas Compressor Turbine Blades steel Flat Rectangles Bars

AMS 5940 Forged Forging Gas steam turbine disks, turbine impeller,turbine blisk,turbine discs,turbine wheel discs

AMS 5940 Forging Steel Forging Forged Gas Steam Turbine Doubled-headed Double end Studs Fasteners Bolts bolting

AMS 5940 Forging Steel gas steam Turbine Guide Rings,seal rings Labyrinth Rings Packing Seal Diaphragm & Seal Ring Rotor End Rings contours Casing Rings

AMS 5940 Forged Forging Steel Gas Steam turbine diaphragm diapharagm nozzles

AMS 5940 Forged Forging Gas Turbine LPT 1st & 2st 2nd Stg Stage Turbine Case Casings

AMS 5940 Forged Forging Steel power plant steam turbine control reheat valve disc Disk

AMS 5940 Forged forging Gas Steam Turbine Valve Spindles/Stems/Rods,

AMS 5940 Forging Steel Gas Steam Turbine MSV/GV/CV/CRV Valve Seats, Valve Cores, Valve Sleeves Spools,,Main Steam Valve Covers Bonnets Sleeves

AMS 5940 forged forging steel pipes tubes shells piping tubing barrels housing, tube sheets,baffle plates, nozzles, channel flanges for boiler, heat

AMS 5940 is an oxidation-resistant low coefficient of thermal expansion (low CTE) superalloy developed for gas turbine applications.

AMS 5940 is strengthened by a precipitation-hardening heat treatment made possible by additions of niobium and aluminum.

In addition, the aluminum content provides excellent resistance to oxidation at high temperatures.The combination of low expansion, high strength and excellent resistance to oxidation makes the alloy especially useful for gas turbine and steam turbine components.

AMS 5940 forged material shall be multiple melted using consumable electrode practice in the remelt cycle. If consumable electrode remeltingis not performed in vacuum, electrodes which have been produced by vacuum induction melting shall be used for remelting."

Check Analysis of AMS 5940 forged parts Composition variations shall meet the applicable requirements of AMS 2269.

AMS 5940 forged parts Shall conform to the percentages by weight shown in Table 1, determined by wet chemical methods in accordance with ASTM E 354, by spectrochemical methods, or by other analytical methods acceptable to purchaser.

| Element | min | max | |||||||

| Carbon | -- | 0.03 | |||||||

| Manganese | -- | 0.50 | |||||||

| Silicon | -- | 0.50 | |||||||

| Phosphorus | -- | 0.015 | |||||||

| Sulfur | -- | 0.005 | |||||||

| Chromium | 2.5 | 3.5 | |||||||

| Nickel | 26.0 | 30.0 | |||||||

| Columbium (Niobium) | 2.5 | 3.5 | |||||||

| Aluminum | 5.0 | 6.0 | |||||||

| Boron | 0.003 | 0.012 | |||||||

| Iron | 24.0 | 27.0 | |||||||

| Titanium | -- | 0.40 | |||||||

| Tantalum | -- | 0.05 | |||||||

|

Copper Cobalt |

-- | 0.50 | |||||||

Room temperature of AMS 5940 forged parts mechnical property

|

|

|||||||||||||||||

| Property | Value | ||||||||||||||||

| Tensile Strength | 160 ksi (1103 MPa) | ||||||||||||||||

| Yield Strength at 0.2% Offset | 105 ksi ( 724 MPa) | ||||||||||||||||

| Elongation in 4D | 12% | ||||||||||||||||

| Reduction of Area | 20% | ||||||||||||||||

1200 °F (649 °C) mechanical property test is as following

Tensile Strength 130 ksi (896 MPa)

Yield Strength at 0.2% Offset 90 ksi (621 MPa)

Elongation in 4D 15%

Reduction of Area 25%

Grain flow of AMS 5904 forgings, except in areas which contain flash-line end grain, shall follow the general contour of the forgings showing no evidence of reentrant grain flow.

Tests for AMS 5904 forging material the following requirements are acceptance tests and shall be performed on each heat or lot as applicable:

Composition and mean coefficient of linear expansion of each heat.

Hardness and average grain size of each lot of bars, forgings, and flash welded rings as solution heat treated.

Room-temperature tensile properties , hardness , and stress-rupture properties of each lot of bars, forgings, and flash welded rings after precipitation heat treatment.

Tolerances of AMS 5904 bars.

Periodic Tests

Tests for the following requirements are periodic tests and shall be performed at a frequency selected by the vendor

unless frequency of testing is specified by purchaser:

Tensile properties at 1200 °F (649 °C) of AMS 5904 forged parts after precipitation heat treatment.

Grain flow of AMS 5904 forging

FOllowing is inspection standard of AMS 5940 forged parts:

ASTM E 8/E 8M Tension Testing of Metallic Materials

ASTM E 18 Rockwell Hardness of Metallic Materials

ASTM E 21 Elevated Temperature Tension Tests of Metallic Materials

ASTM E 112 Determining Average Grain Size

ASTM E 139 Conducting Creep, Creep-Rupture, and Stress-Rupture Tests of Metallic Materials

ASTM E 228 Linear Thermal Expansion of Solid Materials with a Pushrod Dilatometer

ASTM E 292 Conducting Time-for-Rupture Notch Tension Tests of Materials

ASTM E 354 "Chemical Analysis of High-Temperature, Electrical, Magnetic, and Other Similar Iron, Nickel, and Cobalt

Alloys"

ASTM E 1181 Characterizing Duplex Grain Sizes

AMS 5904 each forged parts shall furnish with each shipment a report showing the vendor’s name and the country where the metal was melted (e.g., final melt in the case of metal processed by multiple melting operations) and the results of tests for composition and mean coefficient of linear expansion of each heat, and for hardness and average grain size for each lot of AMS 5904 forged parts solution treated, and for hardness, room temperature tensile properties and stress rupture properties of each lot of AMS 5904 forged parts after precipitation heat treatment, and stating that the product conforms to the other technical requirements. This report shall include the purchase order number, heat and lot numbers, AMS5940D, size, and quantity. If forgings are supplied, the size and melt source of stock used to make the forgings shall also be included."

Welcome your inquiry of AMS 5940) forging forged steel parts