Description

Jiangsu Liangyi is professional manufacturer of Incoloy 909,UNS N19909,Alloy 909,AMS 5884,AMS 5893,Incoloy ALloy 909 open die forging parts and seamless rolled steel forged rings from china

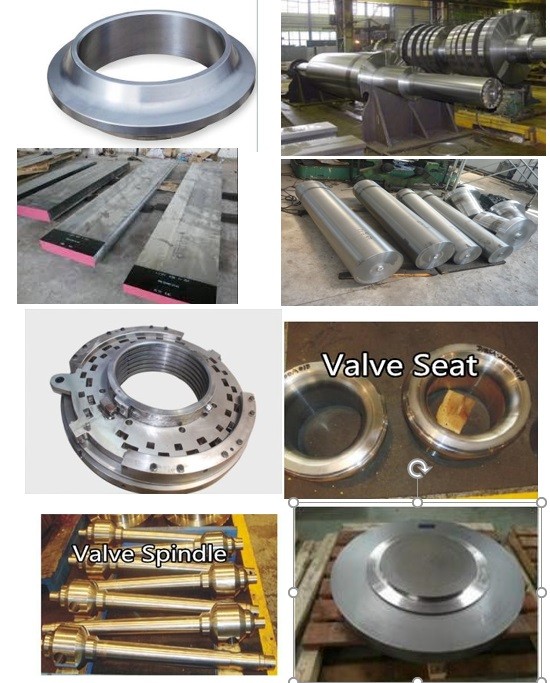

Following is the shape of Incoloy 909,UNS N19909,Alloy 909,AMS 5884,AMS 5893,Incoloy ALloy 909 forging steel material that we could do is:Incoloy 909 Forged Steel round bars square bars Flat bars Rectangles Bars Rods,Incoloy ALloy 909 Forged forging steel rings seamless rolled rings,Alloy 909 Forged Forging Steel Hubs housing shell Sleeves Bushes Bushing Cases Hollow Bars,UNS N19909 Forged Forging Steel Discs Disks Blocks plates,Incoloy 909 Forged Forging Steel Pipe Tubes Tubings Piping Shells Casings Case barrels Housings.

Following is forging products of Incoloy 909,UNS N19909,,Alloy 909,Incoloy ALloy 909 material that is used in following industry

Alloy 909 Forged Forging Turbine and Compressor Labyrinth Shaft Seals

Incoloy 909 Forged Forging Valve Balls,valve Bonnets,valve Body Bodies ,valve Stems,valve closures, valve seat rings, valve core, valve discs,for H type two way 2‐way one way back pressure valves, ball valve,check valve,gate valve

AMS 5884 Forged Forging Steel nuclear Power reactor coolant pumps Rotor Impellers

Incoloy ALloy 909 Forged Forgig Steel nuclear reactor coolant pump Casing Shells body bodis blocks,nuclear reactor coolant pumps containment seal chamber Rooms,nuclear reactor coolant pumps containment seal chamber Rooms

Incoloy ALloy 909 Forged Forging turbomachinery turbo centrifugal compressor Impeller,Compressor Shrouded Impellers

Incoloy ALloy 909 Forged Forging Steel PUMP Casing cover.PUMP BARREL,pump impeller,pump shafts, pump housing, pump shells,pump body,pump wear rings,pump case casing.

Alloy 909 Forged Forging Gas steam turbine disks, turbine impeller,turbine blisk,turbine discs,turbine wheel discs

Incoloy ALloy 909 Forging Steel Forging Forged Gas Steam Turbine Doubled-headed Double end Studs Fasteners Bolts bolting

Incoloy ALloy 909 Forging Steel gas steam Turbine Guide Rings,seal rings Labyrinth Rings Packing Seal Diaphragm & Seal Ring Rotor End Rings contours Casing Rings

Incoloy ALloy 909 Forged Forging Steel Gas Steam turbine diaphragm diapharagm nozzles

AMS 5893 Forged Forging Gas Turbine LPT 1st & 2st 2nd Stg Stage Turbine Case Casings

Incoloy 909 Forged Forging Steel power plant steam turbine control reheat valve disc Disk

UNS N19909 Forged forging Gas Steam Turbine Valve Spindles/Stems/Rods,

Incoloy 909 Forging Steel Gas Steam Turbine MSV/GV/CV/CRV Valve Seats, Valve Cores, Valve Sleeves Spools,,Main Steam Valve Covers Bonnets Sleeves

Incoloy 909 forged forging steel pipes tubes shells piping tubing barrels housing, tube sheets,baffle plates, nozzles, channel flanges for boiler, heat exchanger,pressure vessel,reactors, heaters

Incoloy 909 is is a nickel-iron-cobalt alloy. Alloy 909 is a high strength alloy with impressive constant low coefficient of thermal expansion. Due to Alloy 909 characterisitics it has wide applications where low expansion together with high strength is required. Alloy 909 is widely used in gas turbines, rocket-engine thrust chambers, ordnance hardware, springs, steam-turbine bolts, gauge blocks, instrumentation, glass-sealing applications etc.

Incoloy 909 forging material shall be manufactured from steel produced by vacuum induction melting 1 electro-slag re-melting {VIM/ESR) or by vacuum induction melting 1 vacuum are re-melting (VIM/VAR) process.

The hot working shall be done in such a way that a uniform fine grained microstructure is achieved.

FOllowing is chemical compostion of Incoloy ALloy 909 forged rings

Nickel:35.0-40.0

Cobalt:12.0-16.0

Niobium:4.3-5.2

Titanium:1.3-1.8

Iron .:Balance

Silicon.:0.25-0.50

Aluminum.:0.15 max.

Carbon:0.06 max

Following is heat treament of alloy 909 forged parts

Solution anneal at 1800 F and air cool.

After solution annealing either of 2 aging treatments may be used. For max. tensile properties: 1325 F for 8 hours, furnace cool at 100 F per hour to 1150 F then air cool. For max. hot rupture strength: 1425 F for 12 hours, furnace cool at 100 F per hour to 1150 F and air cool.

Following of Incoloy 909 forging parts heat treatment nechanical property Delivery condition :

Tensile strength (precipitation hardened. value at room temperature) 1300 MPa 189000 psi

Yield strength (@ strain 0.200%, precipitation hardened, value at room temperature) 1140 MPa 165000 psi

Elongation at break (precipitation hardened) 15% 15%

The following details shall be furnished in the test certificate of finished incoloy 909 forged steel:

Heat No. , and melting type.

Dimensional inspection

Details of heat treatment cycle followed.

Results of chemical analysis including tramp elements.

Results of mechanical tests, including hardness test. All individual values shall be reported.Results of ultrasonic tests

Results of surface crack examination

Confirmation of the visual inspection

Confirmation of the verification inspection

Results of additional tests called for in the drawing/order.

Welcome your inquiry of Incoloy 909,UNS N19909,Alloy 909,AMS 5884,AMS 5893,Incoloy ALloy 909 forging forged steel parts

Following is the shape of Incoloy 909,UNS N19909,Alloy 909,AMS 5884,AMS 5893,Incoloy ALloy 909 forging steel material that we could do is:Incoloy 909 Forged Steel round bars square bars Flat bars Rectangles Bars Rods,Incoloy ALloy 909 Forged forging steel rings seamless rolled rings,Alloy 909 Forged Forging Steel Hubs housing shell Sleeves Bushes Bushing Cases Hollow Bars,UNS N19909 Forged Forging Steel Discs Disks Blocks plates,Incoloy 909 Forged Forging Steel Pipe Tubes Tubings Piping Shells Casings Case barrels Housings.

Following is forging products of Incoloy 909,UNS N19909,,Alloy 909,Incoloy ALloy 909 material that is used in following industry

Alloy 909 Forged Forging Turbine and Compressor Labyrinth Shaft Seals

Incoloy 909 Forged Forging Valve Balls,valve Bonnets,valve Body Bodies ,valve Stems,valve closures, valve seat rings, valve core, valve discs,for H type two way 2‐way one way back pressure valves, ball valve,check valve,gate valve

AMS 5884 Forged Forging Steel nuclear Power reactor coolant pumps Rotor Impellers

Incoloy ALloy 909 Forged Forgig Steel nuclear reactor coolant pump Casing Shells body bodis blocks,nuclear reactor coolant pumps containment seal chamber Rooms,nuclear reactor coolant pumps containment seal chamber Rooms

Incoloy ALloy 909 Forged Forging turbomachinery turbo centrifugal compressor Impeller,Compressor Shrouded Impellers

Incoloy ALloy 909 Forged Forging Steel PUMP Casing cover.PUMP BARREL,pump impeller,pump shafts, pump housing, pump shells,pump body,pump wear rings,pump case casing.

Alloy 909 Forged Forging Gas steam turbine disks, turbine impeller,turbine blisk,turbine discs,turbine wheel discs

Incoloy ALloy 909 Forging Steel Forging Forged Gas Steam Turbine Doubled-headed Double end Studs Fasteners Bolts bolting

Incoloy ALloy 909 Forging Steel gas steam Turbine Guide Rings,seal rings Labyrinth Rings Packing Seal Diaphragm & Seal Ring Rotor End Rings contours Casing Rings

Incoloy ALloy 909 Forged Forging Steel Gas Steam turbine diaphragm diapharagm nozzles

AMS 5893 Forged Forging Gas Turbine LPT 1st & 2st 2nd Stg Stage Turbine Case Casings

Incoloy 909 Forged Forging Steel power plant steam turbine control reheat valve disc Disk

UNS N19909 Forged forging Gas Steam Turbine Valve Spindles/Stems/Rods,

Incoloy 909 Forging Steel Gas Steam Turbine MSV/GV/CV/CRV Valve Seats, Valve Cores, Valve Sleeves Spools,,Main Steam Valve Covers Bonnets Sleeves

Incoloy 909 forged forging steel pipes tubes shells piping tubing barrels housing, tube sheets,baffle plates, nozzles, channel flanges for boiler, heat exchanger,pressure vessel,reactors, heaters

Incoloy 909 is is a nickel-iron-cobalt alloy. Alloy 909 is a high strength alloy with impressive constant low coefficient of thermal expansion. Due to Alloy 909 characterisitics it has wide applications where low expansion together with high strength is required. Alloy 909 is widely used in gas turbines, rocket-engine thrust chambers, ordnance hardware, springs, steam-turbine bolts, gauge blocks, instrumentation, glass-sealing applications etc.

Incoloy 909 forging material shall be manufactured from steel produced by vacuum induction melting 1 electro-slag re-melting {VIM/ESR) or by vacuum induction melting 1 vacuum are re-melting (VIM/VAR) process.

The hot working shall be done in such a way that a uniform fine grained microstructure is achieved.

FOllowing is chemical compostion of Incoloy ALloy 909 forged rings

Nickel:35.0-40.0

Cobalt:12.0-16.0

Niobium:4.3-5.2

Titanium:1.3-1.8

Iron .:Balance

Silicon.:0.25-0.50

Aluminum.:0.15 max.

Carbon:0.06 max

Following is heat treament of alloy 909 forged parts

Solution anneal at 1800 F and air cool.

After solution annealing either of 2 aging treatments may be used. For max. tensile properties: 1325 F for 8 hours, furnace cool at 100 F per hour to 1150 F then air cool. For max. hot rupture strength: 1425 F for 12 hours, furnace cool at 100 F per hour to 1150 F and air cool.

Following of Incoloy 909 forging parts heat treatment nechanical property Delivery condition :

Tensile strength (precipitation hardened. value at room temperature) 1300 MPa 189000 psi

Yield strength (@ strain 0.200%, precipitation hardened, value at room temperature) 1140 MPa 165000 psi

Elongation at break (precipitation hardened) 15% 15%

The following details shall be furnished in the test certificate of finished incoloy 909 forged steel:

Heat No. , and melting type.

Dimensional inspection

Details of heat treatment cycle followed.

Results of chemical analysis including tramp elements.

Results of mechanical tests, including hardness test. All individual values shall be reported.Results of ultrasonic tests

Results of surface crack examination

Confirmation of the visual inspection

Confirmation of the verification inspection

Results of additional tests called for in the drawing/order.

Welcome your inquiry of Incoloy 909,UNS N19909,Alloy 909,AMS 5884,AMS 5893,Incoloy ALloy 909 forging forged steel parts