Description

Jiangsu Liangyi professional manufacturer of 1.6957,26NiCrMoV14-5, 26NiCrMoV145, 26NiCrMoV14.5,26 NiCrMoV 14 5 open die forging parts and forged steel gas steam turbine generator rotor shafts, 26NiCrMoV14-5 Gas steam turbine high pressure and intermediate pressure rotors, monobloc rotors, shaft ends, hollow shafts factory from china

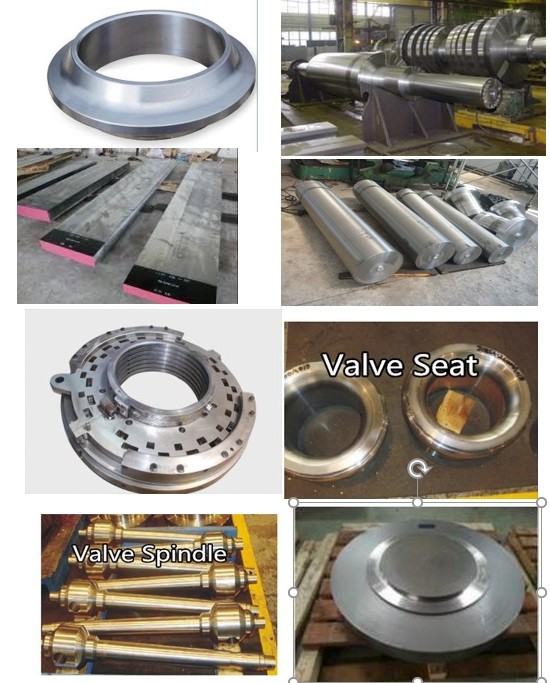

Following is the shape of 1.6957 , 26NiCrMoV14-5, 26NiCrMoV145, 26NiCrMoV14.5,26 NiCrMoV 14 5 Forging steel material that we could do is:26NiCrMoV14-5 Forged Steel round bars square bars Flat bars Rectangles Bars Rods, 26NiCrMoV145 Forged forging steel rings seamless rolled rings, 26 NiCrMoV 14 5 Forged Forging Steel Hubs housing shell Sleeves Bushes Bushing Cases Hollow Bars,26NiCrMoV14.5 Forged Forging Steel Discs Disks Blocks plates, 1.6957 Forged Forging Steel Pipe Tubes Tubings Piping Shells Casings Case barrels Housings.26NiCrMoV14-5 Forged Forging Steel Gas Steam Turbine Rotors Shafts,26 NiCrMoV 14 5 Forged Forging Gas Compressor Turbine Blades turbine Vane steel Flat Rectangles Bars,26NiCrMoV14-5 Forged Forging Steel gas steam Turbine Guide Rings,seal rings Labyrinth Rings Packing Seal Diaphragm & Seal Ring Rotor End Rings contours Casing Rings,,26NiCrMoV14.5 Forged forging Gas Steam Turbine Valve Spindles/Stems/Rods,1.6957 Forging Forged Gas Steam Turbine Doubled-headed Double end Studs Fasteners Bolts

4.1 Melting and Forging of 26NiCrMoV14-5 forged steel steam gas turbine rotor shafts

Vacuum degassed steel with low silicon content (e.g.VCD steel) or remelted steel shall be used and shall be thoroughly forged. The use of any other secondary steel treatment (e. g. CAB) shall be agreed upon in advance with the purchaser in each individual case.

4.2 Heat Treatment of 26NiCrMoV14-5 forging steel gas turbine rotor shafts

The forging of 26NiCrMoV145 forged parts shall be liquid quenched (immersed in water or water spray). Hereby is to be left as far as possible all surplus material at the transition from body part to the journals especially at the location where the trepan core will be removed. The 1.6957 forged gas turbine rotor shaft shall be quenched or sprayed until the temperature in the center of the rotor body is < 80°C. The documentation shall give the duration of quenching or spraying and the final temperature at the surface of the rotor body and the journal. The tempering temperature shall be selected to achieve the prescribed 0,2% yield strength at the best possible toughness. It shall not, however, lie below 600°C. The duration of tempering as well as the controlled cooling rate are to be chosen to achieve minimum residual stresses. The final heat treatment of 26NiCrMoV14.5 forged turbine rotor shafts shall be performed with heating speed less than 40°C/h and cooling speed down to 300°C shall be less than 20°C/h.

.As a result the residual compressive stresses shall not exceed 60 N/mm2 at any point on the surface. Only after reaching a fixed manufacturing plan general measurements can be renounced in agreement with the purchaser. In any case the purchaser reserves the right to check the residual stresses of the 26NiCrMoV145 turbine rotor.

Heat analysis in weight- % for 1.6957 forged material

C ≤ 0,28

Si ≤ 0,25

Mn ≤ 0,40

P ≤ 0,010

S≤ 0,010

Cr 1,40 – 1,80

Mo 0,30 – 0,45

Ni 3,40 – 3,80

V ≤ 0,15

Altot≤ 0,025

Tangential test specimens taken from locations indicated on the drawing shall be tested by the supplier. The single values ofthe 0.2% yield strength and the tensile strength may only distinguish by a maximum of 50 N/mm2.The test rings shall not be cut free before quality heat treatment. The location of tensile and impact specimens shall be in a distance of at least 40 mm from the heat treated surfaces.

The following properties of 26NiCrMoV14-5 forging parts shall be achieved at room temperature:

0,2% yield strength(N/mm2)730 - 830

tensile strength(N/mm2)≤ 1000

Reduction of area(%) ≥ 50

Elongation (l0=5d)(%)≥ 15

Impact strength * (J)≥ 100

Axial Core of 26NiCrMoV14.5 forged turbine rotor shafts

On the bottom end (exciter end) an axial core of ≥ ∅ 60 mm is to be taken from the journal area of the shaft. The position of the axial core is shown on the order drawing or the testing drawing respectively.

Position and number of specimens, also the testing temperatures are established in the newest issue of clients technical manual

The following properties of 26NiCrMoV14-5 forgings must be achieved:

0,2% yield strength(N/mm2)≥ 730

FATT: (°C)≤ - 10

Impact strength *(J)≥ 100

average of 3 Charpy V-notch specimens of 1.6957 forged turbine rotor shafts

The purchaser reserves the right to extend the axial core up to below the barrel. In this case it will be based on an altered drawing.

The following properties must be achieves in the barrel area in radial direction of 1.6957 forged turbine rotor shafts :

0,2% yield strength(N/mm2)≥ 730

FATT:(°C) ≤ + 10

Impact strength *(J)≥ 70

average of 3 Charpy V-notch specimens of 26NiCrMoV14-5 forged turbine rotor shafts

The axial core must be clearly marked, so that its original position can be allocated to the shaft easily. Traceability of the trepanned core to the forging shall be confirmed by the stamp of the manufacturer’s authorized inspector in the area of the ID- no.

If for any reason the axial core is to be taken from the input end (top end), the drawing will no longer be valid. The sampling of the trepanned core then will be carried out according to a new drawing.

All our 26NiCrMoV14-5 forging steel gas turbine rotor shafts can be inspected by by TÜV, DNV-GL, ABS, LR,. BV amd release Inspection certificate EN 10204-3.2

Welcome your inquiry of 1.6957,26NiCrMoV14-5, 26NiCrMoV145, 26NiCrMoV14.5,26 NiCrMoV 14 5 forging forged steel parts