Description

Jiangsu Liangyi professional manufacturer of PH 15-7 Mo(UNS S15700,AISI 632,PH15-7Mo,Alloy 15-7Mo,15-7PH, ph 15-7mo,ASTM A693 Grade 632) open die forging parts and seamless rolled steel forged rings in in delivery Precipitation hardening condition of PH 15-7 Mo H900,PH 15-7 Mo H950,PH 15-7 Mo H1050 from china

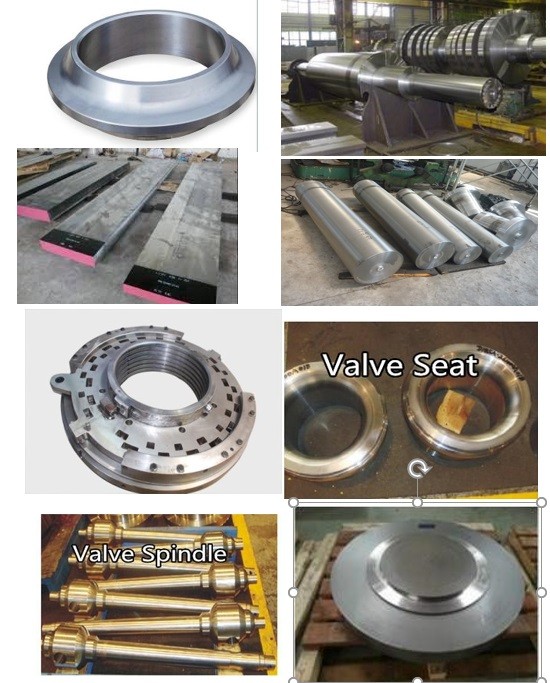

Following is the shape of PH 15-7 Mo(UNS S15700,AISI 632,PH15-7Mo,Alloy 15-7Mo,15-7PH, ph 15-7mo,ASTM A693 Grade 632)forging steel material that we could do is:PH 15-7 Mo Forged Steel round bars square bars Flat bars Rectangles Bars Rods,UNS S15700 Forged forging steel rings seamless rolled rings,PH15-7Mo Forged Forging Steel Hubs housing shell Sleeves Bushes Bushing Cases Hollow Bars,SUS 632 Forged Forging Steel Discs Disks Blocks plates,AISI 632 Forged Forging Steel Pipe Tubes Tubings Piping Shells Casings Case barrels Housings.

Following is forging products of PH 15-7 Mo(UNS S15700,AISI 632,PH15-7Mo,Alloy 15-7Mo,15-7PH, ph 15-7mo,ASTM A693 Grade 632) material that is used in following industry

PH 15-7 Mo Forged Forging Gas Compressor Turbine Blades steel Flat Rectangles Bars

UNS S15700 Forged Forging Gas steam turbine disks, turbine impeller,turbine blisk,turbine discs

AISI 632 Forging Steel Forging Forged Gas Steam Turbine Doubled-headed Double end Studs Fasteners Bolts

Grade 632 Forging Steel gas steam Turbine Guide Rings,seal rings Labyrinth Rings Packing Seal Diaphragm & Seal Ring Rotor End Rings contours Casing Rings

PH15-7Mo forged forging steel pipes tubes shells piping tubing barrels housing, tube sheets, nozzles, channel flanges for boiler, heat exchanger,pressure vessel,reactors, heaters

UNS S15700 forged steel ultra high pressure water jet Waterjet cutting Machine Cutter intensifier pump Sealing Heads

AISI 632 Forged Forging Valve Balls,valve Bonnets,valve Body Bodies ,valve Stems,valve closures, valve seat rings, valve core, valve discs,for H type two way 2‐way one way back pressure valves, ball valve,check valve,gate pump

SUS 632 Forged Forging Steel nuclear Power reactor coolant pumps Rotor Impellers

UNS S15700 Forged Forging Marine Ship Boat Propeller Shafts

UNS S15700 Forged Forging downhole drilling tool Mud Motor Splined Drive shafts,Down hole Electric electrical submersible pumps ESP motor Splined Shaft

Alloy 15-7Mo Forged Forgig Steel nuclear reactor coolant pump Casing Shells body bodis blocks,nuclear reactor coolant pumps containment seal chamber Rooms,nuclear reactor coolant pumps containment seal chamber Rooms

AISI 632 Forged Forging turbomachinery turbo centrifugal compressor Impeller,Compressor Shrouded Impellers

PH 15-7 Mo Forged Forging Steel PUMP Casing cover.PUMP BARREL,pump impeller,pump shafts, pump housing, pump shells,pump body,pump wear rings

PH 15-7 Mo is a semi-austenitic precipitation-hardening stainless steel that provides high strength and hardness,good corrosion resistance and minimum distortion on heat treatment. PH15-7Mo is easily formed in the annealed condition and develops an effective balance of properties by simple heat treatments. For applications requiring exceptionally high strength, cold-reduced PH 15-7 Mo,Stainless Steel in Condition CH 900 is particularly useful for applications permitting limited ductility and workability. This alloy is particularly beneficial for a wide range of applications that include retaining,rings, springs, diaphragms, aircraft bulkheads, welded and brazed honeycomb,paneling and other aircraft components requiring high strength at elevated temperatures.

FOllowing is chemical compostion of PH 15-7 Mo(UNS S15700,AISI 632,PH15-7Mo,Alloy 15-7Mo,15-7PH, ph 15-7mo,ASTM A693 Grade 632)forged steel rings

Carbon (maximum) .09%

Manganese (maximum) 1%

Phosphorus (maximum) .04%

Sulfur (maximum) .04%

Silicon (maximum) 1%

Chromium 14 – 16%

Nickel 6.5 – 7.75%

Molybdenum 2 – 3%

Aluminum .75 – 1.5%

Following of PH 15-7 Mo forging parts heat treatment and mechanical property Delivery condition :

solution Treatment: heat to 1950°F and air cool

TH1050 heat treatment condition of PH 15-7 Mo forged products

Solution Treatment: heat to 1950°F and air cool

Austenite Condition: Heat to 1400°F and hold for 90 minutes and cool to 55°F within 1 hr and hold for 30 minutes

Precitipation Harden: Heat to 1050°F and hold for 90 minutes then air cool

RH950 of heat treatment condition of PH15-7Mo forged rings

Solution Treatment: heat to 1950°F and air cool

Austenite Condition: Heat to 1750°, hold for 10 minutes and cool to room temperature. Then within 1 hour cool to -100°F, hold for 8 hours then warm in air to room temperature

Precitipation Harden: Heat to 950°F and hold for 90 minutes then air cool

CH900 of heat treatment condition of PH15-7Mo forging parts

Condition C: Condition A is transformed to martensite at the mill by cold reduction to Condition C

Fabricate

Precipitation Harden: Heat to 900°F (+/-10) and hold for 60 minutes then air cool

Delivery condition Ageing treatment in H1050: Tensile strength, Rm: >1448 MPa Yield point, RP0,2: >1379 MPa Elongation, A: >7%

Delivery condition Ageing treatment in H950 Tensile strength, Rm: >1655 MPaYield point, Rp0,2: >1552 MPaElongation, A: >6%

Delivery condition Ageing treatment in H900 Tensile strength, Rm: >1828 MPaYield point, Rp0,2: >1793 MPaElongation, A: >2%

All our PH 15-7 Mo(UNS S15700,AISI 632,PH15-7Mo,Alloy 15-7Mo,15-7PH, ph 15-7mo,ASTM A693 Grade 632) forging steel products will have following inspection:

Chemical analyses

Mechanical analyse

UT testing according several norms

MPI testing

Spectral analyse

Hardness measurement according several methods

Tensile and bending tests

Impact test according several methods

Microscope investigation

Huey test

Interkristal corrosion test

Red white test

X-Ray test

3D dimensional check

Magnetic test

Dye penetrant test

Positive Alloy Material Identification (PAMI)

Magnetic particle test

Welcome your inquiry of PH 15-7 Mo(UNS S15700,AISI 632,PH15-7Mo,Alloy 15-7Mo,15-7PH, ph 15-7mo,ASTM A693 Grade 632) forging forged steel parts