Description

Jiangsu Liangyi professional manufacturer of AMS 5886 open die forging parts and seamless rolled steel forged rings. from china

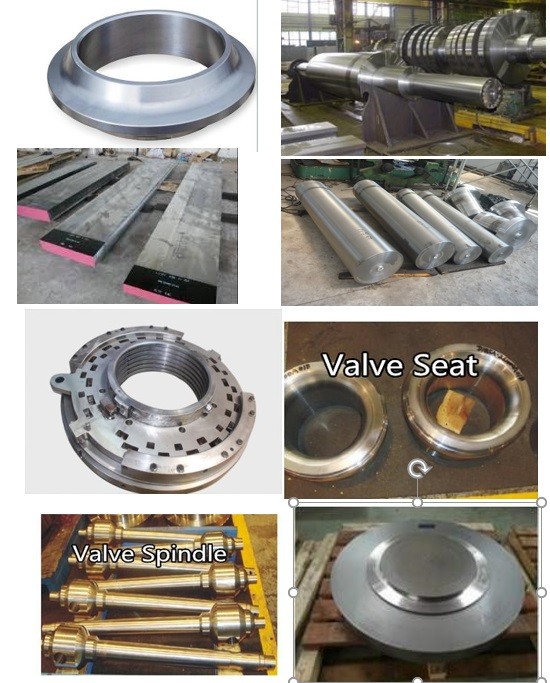

Following is the shape of AMS 5886 forging steel material that we could do is:AMS 5886 Forged Steel round bars square bars Flat bars Rectangles Bars Rods,AMS 5886 Forged forging steel rings seamless rolled rings,AMS 5886 Forged Forging Steel Hubs housing shell Sleeves Bushes Bushing Cases Hollow Bars,AMS 5886 Forged Forging Steel Discs Disks Blocks plates,AMS 5886 Forged Forging Steel Pipe Tubes Tubings Piping Shells Casings Case barrels Housings.

Following is forging products of AMS 5886 material that is used in following industry

AMS 5886 Forged Forging Gas Compressor Turbine Blades steel Flat Rectangles Bars

AMS 5886 Forged Forging Gas steam turbine disks, turbine impeller,turbine blisk,turbine discs

AMS 5886 Forging Steel Forging Forged Gas Steam Turbine Doubled-headed Double end Studs Fasteners Bolts

AMS 5886 Forging Steel gas steam Turbine Guide Rings,seal rings Labyrinth Rings Packing Seal Diaphragm & Seal Ring Rotor End Rings contours Casing Rings

The melting methods of AMS 5886 forged steam turbine blade steel is as follows: The Steel shall be made using the basic electric furnace process with either the Electro-Slag Re-Melt (ESR) or Vacuum- Arc-Re-Melt(VAR) process. Alloy melting requirements shall be compatible with AMS5773E.

AMS 5886 is a specific grade of steel used in demanding industries such as aerospace and defence. This material is known for its outstanding strength and durability, making it an ideal choice for critical components that withstand extreme conditions. AMS 5886 has strict requirements for chemical composition, mechanical properties, and manufacturing methods to ensure consistent quality and reliability. As an expert in the field, trust that choosing AMS 5886 will not only meet but exceed your expectations for performance and longevity.

FOllowing is chemical compostion of AMS 5886 forged steel flat bars

Carbon 0.04 – 0.08 %

Chromium 19.0 – 21.0 %

Cobalt 19.0 – 21.0 %

Iron 0.70% Maximum

Manganese 0.60 % Maximum

Molybdenum 5.60 – 6.10 %

Silicon 0.40 % Maximum

Titanium 1.90 – 2.40 %

Aluminum 0.30 – 0.60 %

Titanium plus Aluminum 2.40 – 2.80 %

Boron 0.005 % Maximum

Sulfur 0.007 % Maximum

Phosphorus 0.015 % Maximum

Copper 0.20 % Maximum

Nickel Remainder

AMS 5886 forging steel turbine blade flat bars heat treat way is as follows:

Solution Treatment - 1150 °C for 1.5-2.5 hours + water quench

Ageing Treatment - 800 °C for 8 hours + air cool

Mechanical properties of AMS 5886 forged round bars shall be tested at room temperature (23 ± 5degree),

Yield strength …………… 58,500 psi

Tensile strength ……….. 78,500 psi

Elongation ……………….. 12 %

For NDT test for all our AMS 5886 forging parts, All Our NDT personnel are PCN and SNT-TC-1A qualified and certified in Non-Destructive Testing to level 2 or 3.All Our Level III and Level II industry certified NDT engineering team is trained inconventional and advanced techniques including radiography, ultrasonic, dye penetrant &magnetic particle to evaluate the material properties of a AMS 5886 forging material without damage.

All our AMS 5886 forging material will have following testing procedure

Visual inspections – Direct and Indirect

Magnetic particle

Dye penetrant – Visible and Fluorescent

Ultra-sonic testing

Radiograph

Metallurgical Testing

Macro & micro

Grain size determination

Charpy Impact testing

V notch Charpy

Hardness testing including micro and

macro Vickers tests

Tensile testing

Microscope imaging

Welcome your inquiry of AMS 5886 forging forged steel parts

Following is the shape of AMS 5886 forging steel material that we could do is:AMS 5886 Forged Steel round bars square bars Flat bars Rectangles Bars Rods,AMS 5886 Forged forging steel rings seamless rolled rings,AMS 5886 Forged Forging Steel Hubs housing shell Sleeves Bushes Bushing Cases Hollow Bars,AMS 5886 Forged Forging Steel Discs Disks Blocks plates,AMS 5886 Forged Forging Steel Pipe Tubes Tubings Piping Shells Casings Case barrels Housings.

Following is forging products of AMS 5886 material that is used in following industry

AMS 5886 Forged Forging Gas Compressor Turbine Blades steel Flat Rectangles Bars

AMS 5886 Forged Forging Gas steam turbine disks, turbine impeller,turbine blisk,turbine discs

AMS 5886 Forging Steel Forging Forged Gas Steam Turbine Doubled-headed Double end Studs Fasteners Bolts

AMS 5886 Forging Steel gas steam Turbine Guide Rings,seal rings Labyrinth Rings Packing Seal Diaphragm & Seal Ring Rotor End Rings contours Casing Rings

The melting methods of AMS 5886 forged steam turbine blade steel is as follows: The Steel shall be made using the basic electric furnace process with either the Electro-Slag Re-Melt (ESR) or Vacuum- Arc-Re-Melt(VAR) process. Alloy melting requirements shall be compatible with AMS5773E.

AMS 5886 is a specific grade of steel used in demanding industries such as aerospace and defence. This material is known for its outstanding strength and durability, making it an ideal choice for critical components that withstand extreme conditions. AMS 5886 has strict requirements for chemical composition, mechanical properties, and manufacturing methods to ensure consistent quality and reliability. As an expert in the field, trust that choosing AMS 5886 will not only meet but exceed your expectations for performance and longevity.

FOllowing is chemical compostion of AMS 5886 forged steel flat bars

Carbon 0.04 – 0.08 %

Chromium 19.0 – 21.0 %

Cobalt 19.0 – 21.0 %

Iron 0.70% Maximum

Manganese 0.60 % Maximum

Molybdenum 5.60 – 6.10 %

Silicon 0.40 % Maximum

Titanium 1.90 – 2.40 %

Aluminum 0.30 – 0.60 %

Titanium plus Aluminum 2.40 – 2.80 %

Boron 0.005 % Maximum

Sulfur 0.007 % Maximum

Phosphorus 0.015 % Maximum

Copper 0.20 % Maximum

Nickel Remainder

AMS 5886 forging steel turbine blade flat bars heat treat way is as follows:

Solution Treatment - 1150 °C for 1.5-2.5 hours + water quench

Ageing Treatment - 800 °C for 8 hours + air cool

Mechanical properties of AMS 5886 forged round bars shall be tested at room temperature (23 ± 5degree),

Yield strength …………… 58,500 psi

Tensile strength ……….. 78,500 psi

Elongation ……………….. 12 %

For NDT test for all our AMS 5886 forging parts, All Our NDT personnel are PCN and SNT-TC-1A qualified and certified in Non-Destructive Testing to level 2 or 3.All Our Level III and Level II industry certified NDT engineering team is trained inconventional and advanced techniques including radiography, ultrasonic, dye penetrant &magnetic particle to evaluate the material properties of a AMS 5886 forging material without damage.

All our AMS 5886 forging material will have following testing procedure

Visual inspections – Direct and Indirect

Magnetic particle

Dye penetrant – Visible and Fluorescent

Ultra-sonic testing

Radiograph

Metallurgical Testing

Macro & micro

Grain size determination

Charpy Impact testing

V notch Charpy

Hardness testing including micro and

macro Vickers tests

Tensile testing

Microscope imaging

Welcome your inquiry of AMS 5886 forging forged steel parts