Description

Jiangsu Liangyi professional manufacturer of 1.4939,X12CrNiMo12,X12CrNiMo 12,X11CrNiMoN12, X 11 CrNiMoN 12 open die forging parts and seamless rolled steel forged rings from china

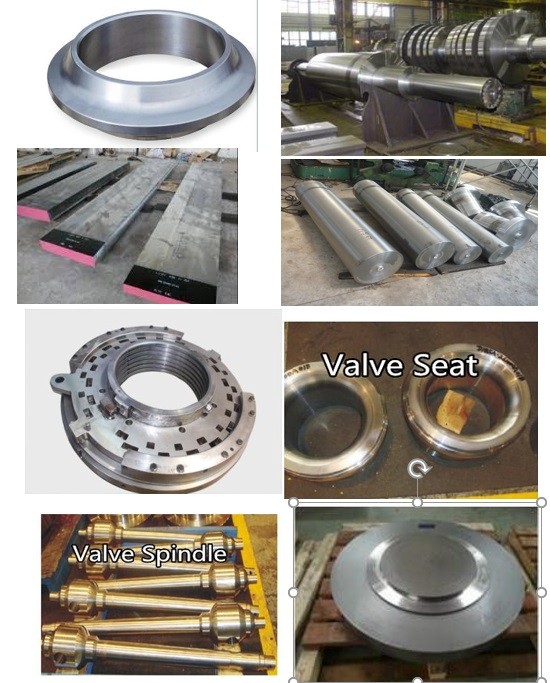

Following is the shape of 1.4939,X12CrNiMo12,X12CrNiMo 12,X11CrNiMoN12,X 11 CrNiMoN 12 Forging steel material that we could do is:1.4939 Forged Steel round bars square bars Flat bars Rectangles Bars Rods, X12CrNiMo 12 Forged forging steel rings seamless rolled rings, X12CrNiMo 12 Forged Forging Steel Hubs housing shell Sleeves Bushes Bushing Cases Hollow Bars, X12CrNiMo 12 Forged Forging Steel Discs Disks Blocks plates, X11CrNiMoN12 Forged Forging Steel Pipe Tubes Tubings Piping Shells Casings Case barrels Housings. X 11 CrNiMoN 12 Forged Forging Steel Gas Steam Turbine Rotors Shafts Turbine Blades turbine impeller, turbine disks turbine blisks Turbine Guide Rings,seal rings Labyrinth Rings Packing Seal Diaphragm & Seal Ring Rotor End Rings contours Casing Rings turbine bolts

Our 1.4939,X12CrNiMo12,X12CrNiMo 12,X11CrNiMoN12 ,X 11 CrNiMoN 12 forged steel parts is normal melting by Basic Electric Furnace (EAF, AOD, VOD) or + Electroslag remelting. (ESR) AS PER CLIENTS NEEDS

For melting 1.4939,X12CrNiMo12,X12CrNiMo 12,X11CrNiMoN12,X 11 CrNiMoN 12 forging steel material, we have following melting equipment

60 t Electric Arc Furnace (EAF) / Power 40 MVA

2 Ladle Furnace (LF)

2 Tank Degassing VD - VOD type

Pits for bottom pouring

ESR Plant (max weight 32 t)

Chemical composition % of steel 1.4939,X12CrNiMo12,X12CrNiMo 12,X11CrNiMoN12,X 11 CrNiMoN 12 forged steel round bars: EN 10302-2008

C 0.08 - 0.15Carbon (C%) Min: 0,08 Max: 0,13

Manganese (Mn%) Min: 0,50 Max: 0,90

Silicon (Si%) ≤ 0,35

Phosphorus (P%) ≤0,025

Sulfur (S%)≤ 0,02

Chrome (Cr%) Min: 11,0 Max: 12,5

Nickel (Ni%) Min: 2,00 Max: 3,00

Molybdenum (Mo%) Min: 1,50 Max: 2,00

Vanadium (V%) Min: 0,25 Max: 0,40

Nitrogen (N%) Min: 0,020 Max: 0,040 N 0.02 - 0.04

Mechanical properties of steel 1.4939,X12CrNiMo12,X12CrNiMo 12,X11CrNiMoN12 ,X 11 CrNiMoN 12 forging steel rings

Tensile strength, Rm: 930 - 1130 MPa

The yield point, Re: > 760 MPa Elongation,

A: >14%

Impact resistance, KV20℃: > 40 J

Reduction, Z: >40%

Hardness in softening annealed condition: ~250 HB

FOllowing is heat treatment way for 1.4939,X12CrNiMo12,X12CrNiMo 12,X11CrNiMoN12 , X 11 CrNiMoN 12 forging steel turbine flat bars

Softening in the temperature of 660 - 690 ℃ Tempering in oil at temperatures of 1030 - 1060 ℃ with cooling to -65 ℃, after which tempering is carried out at a temperature of about 220 - 280 ℃ Hardening with air cooling in the temperature range of 1040 - 1060 ℃ with tempering at temperatures 600-700 ℃ Carburizing at temperatures around 950 ℃

The following NDT inspections shall be performed after all heat treatments of 1.4939 forged turbine parts are performed

Visual inspection of all 1.4939 forging round bars

UT of all X12CrNiMo 12 flat bars as per SEP 1923,inspection number D3 or D2 with dual (twin crystal search unit.100% of the volume shall be examined with the stipulated ecording level Criteria stipulated in SEP 1923 quality class 2 b shall be applied with following modification:EE(single echo)and VE(numerous single echoes)without extension ≥2mm KSR are not permitted Defects above the recording limit shall be marked and it shall be ensured that these X11CrNiMoN12 forging flat bars are not included in the lot delivered.