Description

Jiangsu Liangyi professional manufacturer of 17-7pH(UNS S17700,AISI 631,SUS 631,17-7 pH,17/7 Ph,Grade 631),ASTM A564/A705 grade 631, 17-7ph in ASTM A564/A705 open die forging parts and seamless rolled steel forged rings in in delivery Precipitation hardening condition of 17-7PH H900,17-7PH H950,17-7PH H1050 from china

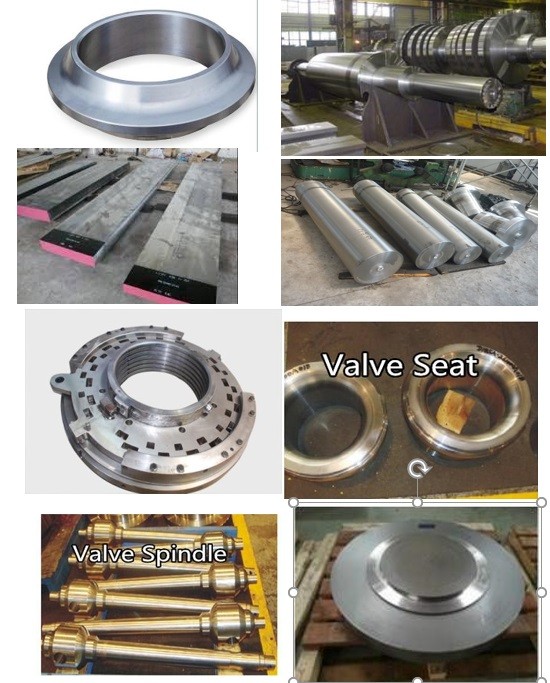

Following is the shape of

17-7pH(UNS S17700,AISI 631,SUS 631,17-7 pH,17/7 Ph,Grade 631)forging steel material that we could do is:17-7pH Forged Steel round bars square bars Flat bars Rectangles Bars Rods,UNS S17700 Forged forging steel rings seamless rolled rings,17-7 pH Forged Forging Steel Hubs housing shell Sleeves Bushes Bushing Cases Hollow Bars,SUS 631 Forged Forging Steel Discs Disks Blocks plates,AISI 631 Forged Forging Steel Pipe Tubes Tubings Piping Shells Casings Case barrels Housings.

Following is forging products of 17-7pH(UNS S17700,AISI 631,SUS 631,17-7 pH,17/7 Ph) material that is used in following industry

17-7pH Forged Forging Gas Compressor Turbine Blades steel Flat Rectangles Bars

UNS S17700 Forged Forging Gas steam turbine disks, turbine impeller,turbine blisk,turbine discs

AISI 631 Forging Steel Forging Forged Gas Steam Turbine Doubled-headed Double end Studs Fasteners Bolts

Grade 631 Forging Steel gas steam Turbine Guide Rings,seal rings Labyrinth Rings Packing Seal Diaphragm & Seal Ring Rotor End Rings contours Casing Rings

17-7 pH forged forging steel pipes tubes shells piping tubing barrels housing, tube sheets, nozzles, channel flanges for boiler, heat exchanger,pressure vessel,reactors, heaters

AISI 631 Forged Forging Valve Balls,valve Bonnets,valve Body Bodies ,valve Stems,valve closures, valve seat rings, valve core, valve discs,for H type two way 2‐way one way back pressure valves, ball valve,check valve,gate pump

SUS 631 Forged Forging Steel nuclear Power reactor coolant pumps Rotor Impellers

SUS 631 forging steel Mould,tooling,die blocks

UNS S17700 Forged Forging Marine Ship Boat Propeller Shafts

UNS S17700 Forged Forging downhole drilling tool Mud Motor Splined Drive shafts,Down hole Electric electrical submersible pumps ESP motor Splined Shaft

17/7 Ph Forged Forgig Steel nuclear reactor coolant pump Casing Shells body bodis blocks,nuclear reactor coolant pumps containment seal chamber Rooms,nuclear reactor coolant pumps containment seal chamber Rooms

AISI 631 Forged Forging turbomachinery turbo centrifugal compressor Impeller,Compressor Shrouded Impellers

17-7pH Forged Forging Steel PUMP Casing cover.PUMP BARREL,pump impeller,pump shafts, pump housing, pump shells,pump body,pump wear rings

17-7pH is Precipitation Hardening Alloy is a semi-austenitic stainless steel which is austenitic in the annealed condition, but martensitic in the hardened condition. Type 17-7PH provides high strength and hardness, excellent fatigue properties, good corrosion resistance and minimum distortion upon heat treatment. It is easily formed in the annealed condition, then hardened to high strength levels by simple heat treatments to Conditions H 950 and TH 1050. The exceptionally high strength of Condition CH 900 offers many advantages where limited ductility and workability are permissible. In its heat treated condition, this alloy provides exceptional mechanical properties at temperatures up to 900 °F (482 °C). 17-7ph forging material is widely used in valve parts, tanks, springs, spring washers, food knives, diaphragms, low and high temperature parts, heat exchangers, special fittings and installations, machine constructions and components. ALso it is intended for the aerospace, petroleum, chemical and petrochemical industries, energy, food and cryogenic industry

FOllowing is chemical compostion of 17-7pH(UNS S17700,AISI 631,SUS 631,17-7 pH,17/7 Ph,Grade 631)forged steel rings

Carbon 0.07% max

Chromium 13.20-14.70%

Manganese 1.00% max

Nickel 5.00-6.00%

Silicon 0.70% max

Molybdenum 1.20-2.00%

Phosphorous 0.035% max

Niobium 0.20-0.70%

Sulphur 0.025% max

Copper 1.20-2.00%

Following of 17-7ph forging parts heat treatment Delivery condition :

different heat treatments of 17-7PH are recommended:

Condition A – mill Annealed at 1950 ± 25° F (1066 ± 14° C).

Condition A1750 – mill Annealed at 1950 ± 25° F (1066 ± 14° C), then heat to 1750 ± 15° F (954 ± 8° C) for 10 minutes and air cool to room temperature.

Condition T – mill Annealed at 1950 ± 25° F (1066 ± 14° C), then heat to 1400 ± 25° F (760 ± 14° C) and hold for 90 minutes. Finally, cool to 60° F (16° C) within 1 hour and hold for 30 minutes.

Condition TH 1050 – mill Annealed at 1950 ± 25° F (1066 ± 14° C), then heat to 1400 ± 25° F (760 ± 14° C) and hold for 90 minutes. Next, cool to 60° F (16° C) within 1 hour and hold for 30 minutes. Finally, heat to 1050 ± 10° F (566 ± 5.5° C) and hold for 90 minutes, then air cool to room temperature.

Condition R 100 – mill Annealed at 1950 ± 25° F (1066 ± 14° C), then heat to 1750 ± 15° F (954 ± 8° C) for 10 minutes and air cool to room temperature. Within 1 hour, start cooling to -100 ± 10° F (73 ± 5.5° C) and hold for 8 hours before air warming to room temperature.

Condition RH 950 – the same as Condition R 100 only with added precipitation hardening at 950 ± 10° F (510 ± 5.5° C) for 60 minutes and then air cooling to room temperature.

Annealed condition of 17-7ph forging parts,- Cond A Rm: >1035 MPa Rp0,2: >380 MPa Elongation, A: >20% Hardness: <92 HRB

Hardened condition 17-7ph forging rings, after ageing - Cond TH1050 Rm: >1170 MPa Rp0,2: >965 MPa Elongation, A: >6% Necking, Z: >25% Hardness: >38 HRC / >352 HB

Hardened condition 17-7ph forging sleeves, after ageing - Cond RH950 Rm: >1280 MPa Rp0,2: >1030 MPa Elongation, A: >6% Necking, Z: >10% Hardness: >41 HRC / >388 HB

All our 17-7pH(UNS S17700,AISI 631,SUS 631,17-7 pH,17/7 Ph,Grade 631) forging steel products will have following inspection:

We have following inspection equipment to inspect of all our 17-7 pH forging steel gas steam turbine blade

a well equipped chemical lab which carries out test analysis on the steel heats made in the steel mill

a well equipped lab which carries out mechanical tensile & resilience tests as well as creep tests

a metallurgic lab for structural macro-micro and inclusion micro metallurgic examinations, according to ISO 17025

non destructive UT/MP/LP tests carried out by experienced and qualified SNT-TA-1A operators

fixed and portable Brinell/3000/10 hardness check equipment

dedicated and certified equipment for dimensional controls.

All our 17-7pH(UNS S17700,AISI 631,SUS 631,17-7 pH,17/7 Ph,Grade 631)forging patys can be release in 10204-3.2 certificate by following third party DNV-GL BUREAU VERITAS,LLOYD’S REGISTER,ABS, RINA,TÜV

Welcome your inquiry of 17-7pH(UNS S17700,AISI 631,SUS 631,17-7 pH,17/7 Ph,Grade 631) forging forged steel parts