Description

Jiangsu Liangyi professional manufacturer of 1.4905,X11CrMoWVNb9-1-1,X11CrMoWVNb911,X11CrMoWVNb9.1.1 open die forging parts and seamless rolled steel forged rings,forged pipes tubes,forging steel gas steam turbine blade steel flat bars from china

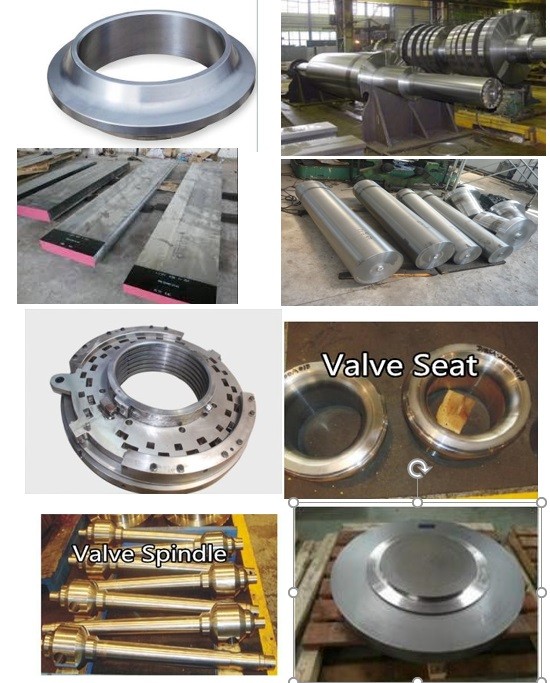

Following is the shape of 1.4905,X11CrMoWVNb9-1-1,X11CrMoWVNb911,X11CrMoWVNb9.1.1 forging steel material that we could do is:1.4905 Forged Steel round bars square bars Flat bars Rectangles Bars Rods,X11CrMoWVNb9-1-1 Forged forging steel rings seamless rolled rings,X11CrMoWVNb911 Forged Forging Steel Hubs housing shell Sleeves Bushes Bushing Cases Hollow Bars,X11CrMoWVNb9.1.1 Forged Forging Steel Discs Disks Blocks plates,1.4905 Forged Forging Steel Pipe Tubes Tubings Piping Shells Casings Case barrels Housings.

Following is forging products of 1.4905,X11CrMoWVNb9-1-1 that is used in gas steam turbine

1.4905,X11CrMoWVNb9-1-1 Forged Forging Steel Gas Steam Turbine blade steel

1.4905 forged forging steel gas steam turbine rotor shafts

X11CrMoWVNb9-1-1 Forged Forging Gas Compressor Turbine Blades steel Flat Rectangles Bars

X11CrMoWVNb911 Forged Forging Steel Gas Steam turbine diaphragm diapharagm nozzles

X11CrMoWVNb9.1.1 Forged Forging Steel gas steam Turbine Guide Rings,seal rings Labyrinth Rings Packing Seal Diaphragm & Seal Ring Rotor End Rings contours Casing Rings/Blade Fitting Rings

X11CrMoWVNb9-1-1 Forging Forged Steel Gas Turbine Wheels Discs turbine impeller turbine blisks

1.4905 Forged Forging Gas Turbine LPT 1st & 2st 2nd Stg Stage Turbine Case Casings

X11CrMoWVNb9-1-1 Forged Forging Rolled Steel Gas Turbine LPT 1st & 2st 2nd Stg Stage Steam Turbine shrouds turbines journal and thrust bearing

X11CrMoWVNb911 Forged Forging Steel power plant steam turbine control reheat valve disc Disk

X11CrMoWVNb9.1.1 Forged forging Gas Steam Turbine Valve Spindles/Stems/Rods,

1.4905 Forging Forged Gas Steam Turbine Doubled-headed Double end Studs Fasteners Bolts

X11CrMoWVNb911 Forging Steel Gas Steam Turbine MSV/GV/CV/CRV Valve Seats, Valve Cores, Valve Sleeves Spools,,Main Steam Valve Covers Bonnets Sleeves

X11CrMoWVNb9-1-1 Forged Forging Steel Gas Steam Turbine Oil Guards nozzle Bearing Gland Seal Sealing Rings,

1.4905 forging Steam Gas Turbine Inlet Guide Vane IGV Control Ring Lower Upper Half,Outer Inner Transition Ducts,

1.4905,X11CrMoWVNb9-1-1 forged Forged Forging Rolled Gas Steam Turbine Inner Outer Heat Shields,

X11CrMoWVNb9-1-1 is special martensitic creep-resisting steel and Among wrought stainless steels, the composition of EN 1.4905 stainless steel is notable for including boron (B) and tungsten (W). Boron is used to improve hardenability. It has a substantial effect when added in even tiny amounts. It can also facilitate sintering. Tungsten interacts with other alloying elements to a greater extent than usual, which makes it hard to broadly characterize its effects.

FOllowing is production standard of 1.4905 forging steam turbine material

EN 10302: 2008 Creep resisting steels, nickel and cobalt alloys

EN 10216-2: 2014 Seamless steel tubes for pressure purposes. Technical delivery conditions. Non-alloy and alloy steel tubes with specified elevated temperature properties

EN 10088-1: 2005 Stainless steels. List of stainless steels

FOllowing is melting methods of X11CrMoWVNb9-1-1 forged steel turbine parts:EAF + VD + LF / BEF + ESR

All our Certification of our finished forged X11CrMoWVNb911 forging parts is according EN 10204 / 2.2, EN 10204 / 3.1, EN 10204 / 3.2 Approvals AD-WO/TRD 100,KTA 3201.1 / 3211.1 / 3401.1 / 3204,KTA 1401 acc. AVS D 100/50 VGB, EnBW, e-on, RWE, Vattenfall,PED 97/23/EG,ASME III,AREVA / EDF and also can have Certification by Independent organisations by: TüV, LRS, BV, DNV, ABS, RINA, GL, KR, NIPPON, NORSOK or other inspection organisation

Following is production process of X11CrMoWVNb9-1-1 forging steel parts

Forging process flow quality control: Raw material steel ingot into warehouse(test the chemical content) → Cutting→ Forged process→ Post forging heat treatment(N+T)→ UT→ Rough Machining→ UT → QT→ Inspection(UT, mechanical properties, hardness, grain size)→ Grooving→ Stress relieve Tempering → Machining holding postion for rotor when HST→ HST→ Inspection (dimension)→ Packing and Marking(steel stamp, mark)→ Storage Shipment

Chemical composition % of steel X11CrMoWVNb9-1-1 forged steel round bars is as following

Iron (Fe) 86.2 to 88.8

Chromium (Cr) 8.5 to 9.5

Molybdenum (Mo) 0.9 to 1.1

Tungsten (W) 0.9 to 1.1

Manganese (Mn) 0.3 to 0.6

Silicon (Si) 0.1 to 0.5

Nickel (Ni) 0.1 to 0.4

Vanadium (V) 0.18 to 0.25

Carbon (C) 0.090 to 0.13

Niobium (Nb) 0.060 to 0.1

Nitrogen (N) 0.050 to 0.090

Aluminum (Al) 0 to 0.040

Phosphorus (P) 0 to 0.020

Sulfur (S) 0 to 0.010

Boron (B) 0.00050 to 0.0050

Mechanical properties of forging steel X11CrMoWVNb9-1-1 (1.4905) parts us as follows

Rm - Tensile strength (MPa) (+QT) 620-850

Rp0.2 0.2% proof strength (MPa) (+QT) 450

KV - Impact energy (J) longitud., (+NT) +20°

40

KV - Impact energy (J) transverse, (+NT) +20°

27

A - Min. elongation at fracture (%) (+QT) 19

All our X11CrMoWVNb9-1-1 (1.4905) forged pipes will have following inspection:

Chemical analyses

Mechanical analyse

UT testing according several norms

MPI testing

Spectral analyse

Hardness measurement according several methods

Tensile and bending tests

Impact test according several methods

Microscope investigation

Huey test

Interkristal corrosion test

Red white test

X-Ray test

3D dimensional check

Magnetic test

Dye penetrant test

Positive Alloy Material Identification (PAMI)

Magnetic particle test