Description

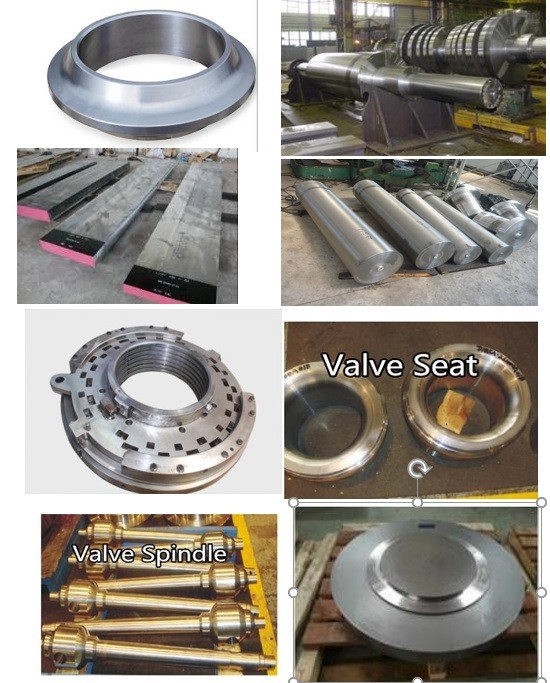

Following is the shape of 2.4663,NiCr23Co12Mo forging steel material that we could do is:2.4663 Forged Steel round bars square bars Flat bars Rectangles Bars Rods,2.4663 Forged forging steel rings seamless rolled rings,2.4663 Forged Forging Steel Hubs housing shell Sleeves Bushes Bushing Cases Hollow Bars,NiCr23Co12Mo Forged Forging Steel Discs Disks Blocks plates,2.4663 Forged Forging Steel Pipe Tubes Tubings Piping Shells Casings Case barrels Housings.

Following is forging products of 2.4663,NiCr23Co12Mo material that is used in following industry

2.4663 Forged Forging Turbine and Compressor Labyrinth Shaft Seals

2.4663 Forged Forging Valve Balls,valve Bonnets,valve Body Bodies ,valve Stems,valve closures, valve seat rings, valve core, valve discs,for H type two way 2‐way one way back pressure valves, ball valve,check valve,gate valve

2.4663 Forged Forging Steel nuclear Power reactor coolant pumps Rotor Impellers

2.4663 Forged Forging venturi cone meter Body Bodies Blocks

NiCr23Co12Mo Forged Forging Steel gate valves Body Bodies bespoke flat bars

2.4663 forging steel Oil measurement valve Spool Ultrasonic flow meter bodies Body

2.4663 Forged Forging Steel double studded adapter flange

2.4663 Forged Forgig Steel nuclear reactor coolant pump Casing Shells body bodis blocks,nuclear reactor coolant pumps containment seal chamber Rooms,nuclear reactor coolant pumps containment seal chamber Rooms

2.4663 Forged Forging turbomachinery turbo centrifugal compressor Impeller,Compressor Shrouded Impellers

2.4663 Forged Forging Steel PUMP Casing cover.PUMP BARREL,pump impeller,pump shafts, pump housing, pump shells,pump body,pump wear rings,pump case casing.

2.4663 Forged Forging forge Steel transition Cone

NiCr23Co12Mo Forged Forging Steel Pressure Vessel Reactor Nozzles

2.4663 Forged Forging Gas Compressor Turbine Blades steel Flat Rectangles Bars

2.4663 Forged Forging Gas steam turbine disks, turbine impeller,turbine blisk,turbine discs,turbine wheel discs

2.4663 Forging Steel Forging Forged Gas Steam Turbine Doubled-headed Double end Studs Fasteners Bolts bolting

2.4663 Forging Steel gas steam Turbine Guide Rings,Turbine shroud rings,seal rings Labyrinth Rings Packing Seal Diaphragm & Seal Ring Rotor End Rings contours Casing Rings

2.4663 Forged Forging Steel Gas Steam turbine diaphragm diapharagm nozzles

2.4663 Forged Forging Gas Turbine LPT 1st & 2st 2nd Stg Stage Turbine Case Casings

2.4663 Forged Forging Steel power plant steam turbine control reheat valve disc Disk

NiCr23Co12Mo Forged forging Gas Steam Turbine Valve Spindles/Stems/Rods,

2.4663 Forging Steel Gas Steam Turbine MSV/GV/CV/CRV Valve Seats, Valve Cores, Valve Sleeves Spools,,Main Steam Valve Covers Bonnets Sleeves

2.4663 forged forging steel pipes tubes shells piping tubing barrels housing, tube sheets,baffle plates, nozzles, channel flanges for boiler, heat exchanger,pressure vessel,reactors, heaters

NiCr23Co12Mo Forged Forging Nickel Alloy Bore Protector

2.4663 is a nickel-chromium-cobalt alloy that is known primarily for its exceptional metallurgical stability. Also sold under the brand name Inconel® 617, this alloy brings a wide variety of other outstanding properties to users, including:

Resistance to oxidation at high temperatures, thanks to added aluminum

Good resistance to a wide range of corrosive aqueous environmentsResistant to a number of different damaging reducing and oxidizing media

Cobalt and molybdenum impart a solid-solution strengthening

2.4668 forged parts production shall be performed by using one of the following methods:

Electric arc welding process (remelting if necessary)

Induction furnace process vacuum melting (or remelting, if necessary – e.g. ESR

Argon-Oxygen Decarburization (AOD) method.

FOllowing is chemical compostion of 2.4663 forged parts

Fe max 2

C 0.05 - 0.1

Si max 0.2

Mn max 0.2

P max 0.01

S max 0.01

Cr 20 - 23

Mo 8.5 - 10

Co 11 - 14

Ti 0.2 - 0.6

Al 0.7 - 1.4

Cu max 0.5

B max 0.006

Ni - remainder

Following of 2.4663 forging parts heat treatment nechanical property Delivery condition :

Mechanical properties shall be tested on samples cut away from the tangential test ring taken from 2.4663 forged and rolled rings in the delivery condition.

The residual test material, with the serial number stamped on it, must be delivered to clients

Specimens shall be taken from both tangential and transverse directions.

Impact test at room temperature and Brinell hardness test have to be performed according to EN ISO 148-1 and EN ISO 6506-1, respectively.

Tensile tests have to be performed according to EN ISO 6892-1 and -2, with specimens taken possibly transverse to the main direction of plastic transformation.

| Table 6-1 Specimens mechanical requirements | ||||||||||||||||||||||||||||

|

T [°C] |

Rp0.2 [MPa] |

Rm [MPa] |

A [%] (L0=5.65√S0 or L0=5d) |

Z [%] |

KV [J] |

HBW 10/3000 | ||||||||||||||||||||||

| RT(1) | 20 | ≥270 | ≥630 | ≥30 | ≥50 | ≥100(1) | info | |||||||||||||||||||||

| HT(1) | 650 | ≥187 | Info | Info | Info | – | – | |||||||||||||||||||||

|

1 2 |

RT → Room temperature; HT → High temperature Average value of 3 specimens; minimum single value 70 J. |

|||||||||||||||||||||||||||

The microstructure must be uniform and free from extensive segregation and other inhomogenities. Determination of grain size has to be performed according to EN ISO 643.

Grain size checking shall be performed for each ring, which has to achieve a grain size of 1. The presence of random located larger grains in the range of 0 to 1 classes is allowed.

Ultrasonic test of 2.4663 forged sleeves is as follows

The surface condition must be in order to guarantee a regular performance of the test. The ultrasonic test shall be performed on 100% of the examined surface.

Ultrasonic test evaluation criteria are listed in the following table:

| Table 9.2-1 UT evaluation criteria | ||||||||||||||||||||||||||||

|

Permissible defect size [mm FBH(1)] |

Reporting limits diameter [mm] |

Defect frequency(2) [number per m] |

||||||||||||||||||||||||||

| ≤ 5 | ≤ 3 | ≤ 4 | ||||||||||||||||||||||||||

|

1 2 |

FBH → Flat bottomed hole The distance between two indications must be ≥ 2x the lenght of the greatest one. |

|||||||||||||||||||||||||||

be removed by machining, the test repetition is not necessary.

To determinate precisely the defect extention, all faulty points shall be scanned using different detectors if necessary.

The ultrasonic test shall be performed with probes having the following features:

vertical transducers, which shall be moved in axial and radial directions; 45° angled transducers, which shall be moved both in radial-tangential and radial-axial directions. Moreover, the scanning test with 45° transducers shall be performed both in clockwise and anticlockwise direction.

Following is reference inspection document for 2.4663 forged rings

EN 10204 Metallic products - Types of inspection documents

EN 10302 Creep resisting steels, nickel and cobalt alloys

EN 13018 Non-destructive testing - Visual testing - General principles

EN ISO 148-1 Metallic materials - Charpy pendulum impact test - Part 1: Test method

EN ISO 643 Micrographic determination of the apparent grain size

EN ISO 6506-1 Metallic materials - Brinell hardness test - Part 1: Test method

EN ISO 6892-1 " Metallic materials - Tensile testing - Part 1: Method of test at room

temperature."

EN ISO 6892-2 " Metallic materials - Tensile testing - Part 2: method of test at high temperature"

EN ISO 9001 Quality management system

EN ISO 9712 Non-destructive testing - Qualification and certification of NDT personnel