Description

Jiangsu Liangyi professional manufacturer of 1.4922 ,X20CrMoV11-1,X20CrMoV12-1 ,X20CrMoNV11-1-1,X20CrMoV111,X20CrMoV11.1,X20 Cr Mo V11-1, X 20 CrMoV 12-1 open die forging parts, forging boiler pipes tubes and forged steel gas steam turbine generator rotor shafts ,X21CrMoV12.1 forged steel Gas steam turbine rotor shafts, turbine blade steel factory from china

1.4922 ,X20CrMoV11-1,X20CrMoV12-1 ,X20CrMoNV11-1-1 is a heat treated and martensitic structure Creep resisting steels , 1.4922 is normallyt designed for pressures and high temperature applications up to 600 DEGREE for devices mainly used in the energy, petroleum and chemical industries. 1.4922 ,X20CrMoV11-1,X20CrMoV12-1 forging steel material is mainly supplied in the form of Power plant engineering, Mechanical Engineering, Power Generation, forged Components for high heat resistant pipelines, steam boiler and turbine construction and parts for the chemical industry and reactor technology

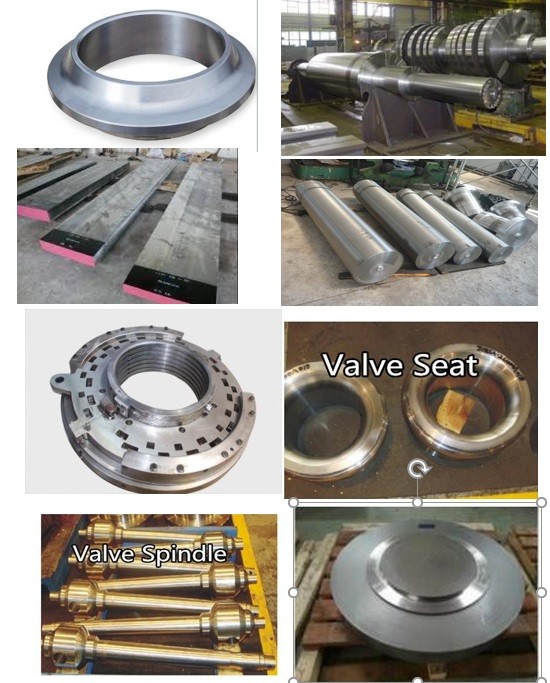

Following is the shape of 1.4922 ,X20CrMoV11-1,X20CrMoV12-1 ,X20CrMoNV11-1-1 Forging steel material that we could do is:X20CrMoV11-1 Forged Steel round bars square bars Flat bars Rectangles Bars Rods, X20CrMoV11.1 Forged forging steel rings seamless rolled rings, X20CrMoNV11-1-1 Forged Forging Steel Hubs housing shell Sleeves Bushes Bushing Cases Hollow Bars,X20 Cr Mo V11-1 Forged Forging Steel Discs Disks Blocks plates, 1.4922 Forged Forging Steel Pipe Tubes Tubings Piping Shells Casings Case barrels Housings.X20CrMoV111 Forged Forging Steel Gas Steam Turbine Rotors Shafts,X21CrMoV121 Forged Forging Gas Compressor Turbine Blades turbine Vane steel Flat Rectangles Bars,X20CrMoV11.1 Forged Forging Steel gas steam Turbine Guide Rings,seal rings Labyrinth Rings Packing Seal Diaphragm & Seal Ring Rotor End Rings contours Casing Rings,,X20CrMoV12-1 Forged forging Gas Steam Turbine Valve Spindles/Stems/Rods,X20 Cr Mo V11-1 Forging Forged Gas Steam Turbine Doubled-headed Double end Studs Fasteners Bolts

FOllowing is production standard of X20CrMoV11.1 forging steel parts: EN 10302: 2008, EN 10222-2: 2000,EN 10216-2: 2014, EN 10088-1: 2005

Our 1.4922 ,X20CrMoV11-1,X20CrMoV12-1 ,X20CrMoNV11-1-1 forged steel raw material is normal melting by Basic Electric Furnace (EAF, AOD, VOD) or + Electroslag remelting. (ESR) AS PER CLIENTS NEEDS

CHEMICAL COMPOSITION (WEIGHT %) of 1.4922 ,X20CrMoV11-1,X20CrMoV12-1 ,X20CrMoNV11-1-1 forged steel turbine parts is as followings

Carbon (C%)Aluminium 0.02 % max.

Boron 0.0015 %

Carbon 0.17 - 0.23 %

Chromium 10.0 - 11.5 %

Manganese 0.4 - 0.9 %

Molybdenum 0.5 - 0.8 %

Nickel 0.2 - 0.6 %

Niobium 0.25 - 0.55 %

Nitrogen 0.05 - 0.1 %

Phosphorus 0.03 %max.

Silicon 0.5 % max.

Sulfur 0.015 % max.

Vanadium 0.1 - 0.3 %

Following is heat treatment way of 1.4922 ,X20CrMoV11-1,X20CrMoV12-1 ,X20CrMoNV11-1-1 steel pipes

Soft Annealing of X20CrMoV11-1 forging rings

Heat to 730-780c, cool slowly in furnace or air.

Stress Relieving of X20CrMoNV11-1-1 forged tubes

Stress relieving to remove machining stresses should be carried out by heating to 650-6809c,holding for one hour at heat, followed by air cooling. This operation is performed to reducedistortion during heat treatment.

Hardening of X20CrMoV12-1 forging sleeves

Harden from a temperature of 1020-10709c followed by air or oil quenching. Structure ismartensite.

Tempering of X20CrMoV11-1 forging round bars

Tempering temperature: 720-7809c.

Mechanical properties of steel 1.4922 ,X20CrMoV11-1,X20CrMoV12-1 ,X20CrMoNV11-1-1 Forging steel pipes sleeves is as follows

Rm - Tensile strength (MPa) (+NT) 690-840

Rm - Tensile strength (MPa) (+QT) 700-850

ReH - Minimum yield strength (MPa) (+NT) 490

Rp0.2 0.2% proof strength (MPa) (+QT) 500

KV - Impact energy (J) longitud., (+NT) +20°Min 40

KV - Impact energy (J) longitud., (+QT) +20°27-39

KV - Impact energy (J) transverse, (+QT) +20°Min 27

A - Min. elongation at fracture (%) longitud., (+NT) Min 17

A - Min. elongation at fracture (%) transverse, (+NT) Min 14

A - Min. elongation at fracture (%) (+QT) Min 15-16

Following is forging process of 1.4922 ,X20CrMoV11-1,X20CrMoV12-1 ,X20CrMoNV11-1-1 forging steel parts

Forging process flow quality control: Raw material steel ingot into warehouse(test the chemical content) → Cutting→ Forged process→ Post forging heat treatment(N+T)→ UT→ Rough Machining→ UT → QT→ Inspection(UT, mechanical properties, hardness, grain size)→ Grooving→ Stress relieve Tempering → Machining holding postion for rotor when HST→ HST→ Inspection (dimension)→ Packing and Marking(steel stamp, mark)→ Storage Shipment

Welcome your inquiry of 1.4922 ,X20CrMoV11-1,X20CrMoV12-1 ,X20CrMoNV11-1-1 forging forged steel parts