Description

Jiangsu Liangyi is professional manufacturer of AMS 5743,AMS 5744 open die forging forged parts forged forging rings and forged forging steel gas steam turbine parts factory from china

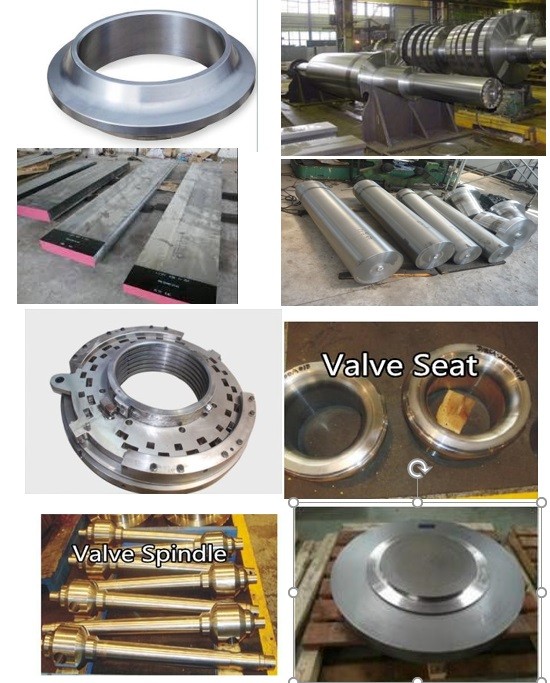

Following is the shape of AMS 5743,AMS 5744 forging steel material that we could do is:AMS 5743,AMS 5744 Forged Steel round bars square bars Flat bars Rectangles Bars Rods,AMS 5743 Forged forging steel rings seamless rolled rings,AMS 5743 Forged Forging Steel Hubs housing shell Sleeves Bushes Bushing Cases Hollow Bars,AMS 5744 Forged Forging Steel Discs Disks Blocks plates,AMS 5743 Forged Forging Steel Pipe Tubes Tubings Piping Shells Casings Case barrels Housings.

Following is forging products of AMS 5743 that is used in gas steam turbine

AMS 5743 Forged Forging Steel Gas Steam Turbine blade steel

AMS 5743 Forged Forging Steel Gas Steam turbine diaphragm diapharagm nozzles

AMS 5743 Forged Forging Steel gas steam Turbine Guide Rings,seal rings Labyrinth Rings Packing Seal Diaphragm & Seal Ring Rotor End Rings contours Casing Rings/Blade Fitting Rings

AMS 5743 Forging Forged Steel Gas Turbine Wheels Discs turbine impeller turbine blisks

AMS 5744 Forged Forging Gas Turbine LPT 1st & 2st 2nd Stg Stage Turbine Case Casings

AMS 5744 Forged Forging Rolled Steel Gas Turbine LPT 1st & 2st 2nd Stg Stage Steam Turbine shrouds turbines journal and thrust bearing

AMS 5744 Forged Forging Steel power plant steam turbine control reheat valve disc Disk

AMS 5743 Forged forging Gas Steam Turbine Valve Spindles/Stems/Rods,

AMS 5743 Forging Forged Gas Steam Turbine Doubled-headed Double end Studs Fasteners Bolts

AMS 5743 Forging Steel Gas Steam Turbine MSV/GV/CV/CRV Valve Seats, Valve Cores, Valve Sleeves Spools,,Main Steam Valve Covers Bonnets Sleeves

AMS 5743 Forged Forging Steel Gas Steam Turbine Oil Guards nozzle Bearing Gland Seal Sealing Rings,

AMS 5743 forging Steam Gas Turbine Inlet Guide Vane IGV Control Ring Lower Upper Half,Outer Inner Transition Ducts,

AMS 5743 forged Forged Forging Rolled Gas Steam Turbine Inner Outer Heat Shields,

The maximum diamter of AMS 5743 forging steel parts in we could produce is 3 meter, the maximum weight of AMS 5743 forging steel material that we could produce is 25 tons, the maximum length of AMS 5744 forging steel products that we could do is 12 meter

Our AMS 5743 forged steel raw material is normal melting by Basic Electric Furnace (EAF, AOD, VOD) or + Electroslag remelting. (ESR) AS PER CLIENTS NEEDS

AMS 5743, AMS 5743 is chromium-nickel-molybdenum stainless steel . Alloy 355 may have an austenitic structure and formability similar to other austenitic stainless steels or a martensitic structure and high strength comparable to other martensitic stainless steels depending on the heat treatment. High strengths may be also be attained by cold working.

The chemical compostion of AMS 5743 forging parts that we could produce is as followings

Element Min Max

C 0.10 0.15

Cr 15.00 16.00

Mn 0.50 1.25

Mo 2.50 3.25

N 4.00 5.00

Ni 0.07 0.13

P - 0.040

S - 0.030

Si - 0.50

FOllowing is heat treatment mechanical property of AMS 5743,AMS 5744 forging steel turbine parts

AM 355 Bar 850°F L Yile strength 1255MPA Tensile strength 1489MPA Elongation 19% reduction 38%

AM 355 Bar 850°F T Yile strength 1276MPA Tensile strength 1517MPA Elongation 12% reduction 21%

AM 355 Bar 1000°F L Yile strength 1179MPA Tensile strength 1276MPA Elongation 19% reduction 57%

AM 355 Bar 1000°F T Yile strength 1165MPA Tensile strength 1276MPA Elongation 15% reduction 40%

All our AMS 5743,AMS 5744 forged material will have following inspection:

Chemical analyses

Mechanical analyse

UT testing according several norms

MPI testing

Spectral analyse

Hardness measurement according several methods

Tensile and bending tests

Impact test according several methods

Microscope investigation

Huey test

Interkristal corrosion test

Red white test

X-Ray test

3D dimensional check

Magnetic test

Dye penetrant test

Positive Alloy Material Identification (PAMI)

Magnetic particle test

Welcome your inquiry of AMS 5743,AMS 5744 forging forged steel parts