Description

Jiangsu Liangyi professional manufacturer of 1.7709,21CrMoV5-7,21crmov57,21crmov5.7,21 CrMoV 5-7 open die forging parts and seamless rolled steel forged rings,forged pipes tubes,21CrMoV5-7 forging steel gears,pinion shafts,gear shafts, spindles,1.7709 forged forging steel gas steam turbine blade bolts rotor shafts from china

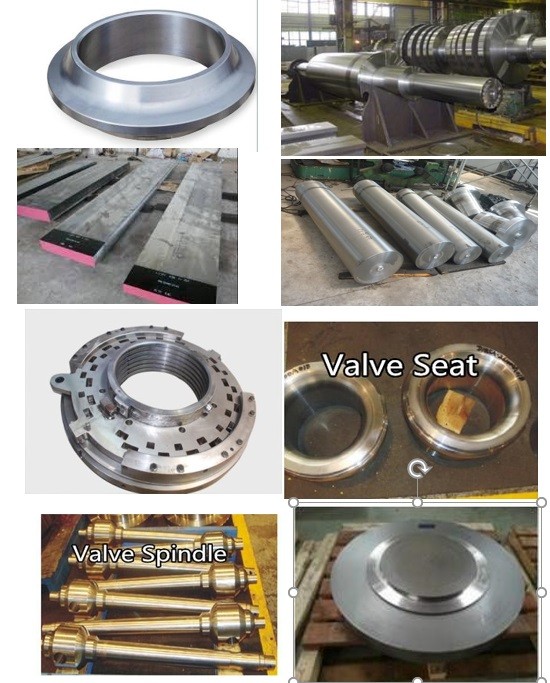

Following is the shape of 1.7709,21CrMoV5-7,21crmov57,21crmov5.7,21 CrMoV 5-7 forging steel material that we could do is:1.7709 Forged Steel round bars square bars Flat bars Rectangles Bars Rods,21crmov57 Forged forging steel rings seamless rolled rings,21crmov5-7 Forged Forging Steel Hubs housing shell Sleeves Bushes Bushing Cases Hollow Bars,21crmov5.7 Forged Forging Steel Discs Disks Blocks plates,21crmov57 Forged Forging Steel Pipe Tubes Tubings Piping Shells Casings Case barrels Housings.

Following is forging products of 1.7709,21CrMoV5-7 that is used in following industry

21CrMoV5-7 forged forging steel pipes tubes shells piping tubing barrels housing, tube sheets, nozzles, channel flanges for boiler, heat exchanger,pressure vessel,reactors, heaters

21CrMoV57 Forged Forging Gas steam turbine rotor shafts

21CrMoV57 Forged Forging Gas steam turbine disks, turbine impeller,turbine blisk,turbine discs, turbine wheels

1.7709 Forging Steel Forging Forged Gas Steam Turbine Doubled-headed Double end Studs Fasteners Bolts

1.7709,21CrMoV5-7 forged forging steel gear, gear shafts,spindle, pinion shafts

1.7709 is Cr-Mo-V steel low-alloyed, bainitic, suitable for higher temperatures and heat-stable. For large forgings – easily formable and machinable. Corrosion-resistant in an environment of hydrogen at high pressure up to a temperature of approx. 320 °C and water steam up to a temperature of approx. 600 °C. Mainly for fastening energy and chemical equipment components, steam turbine rotors, shafts and compressor impeller wheels

FOllowing is production and inspection standard of 1.7709,21CrMoV5-7 steel round bars

EN 10269, DIN 17240, AD 2000 W 0, AD 2000 W 7, TRD 106, TRB 100, TLV 9186-01

For melting 1.7709 forged steel parts, we have following melting equipment

60 t Electric Arc Furnace (EAF) / Power 40 MVA

2 Ladle Furnace (LF)

2 Tank Degassing VD - VOD type

Pits for bottom pouring

ESR Plant (max weight 32 t)

All our 1.7709,21CrMoV5-7 forging steel rings can be release in 10204-3.2 certificate by following third party DNV-GL BUREAU VERITAS,LLOYD’S REGISTER,ABS, RINA,TÜV

FOllowing is chemical compostion of 1.7709 forging Pipes

C: 0,17 - 0,25 %

Cr: 1,2 - 1,5 %

Mn: 0,4 - 0,8 %

Mo: 0,55 - 0,8 %

Ni: max. 0,6 %

P: max. 0,025 %

S: max. 0,03 %

Si: max. 0,4 %

V: 0,2 - 0,35 %

FOllowing is heat treatment way and mechanical property of 1.7709 forged steel turbine bolts

Annealed condition: heat to 830 °C followed by slow cooling.

- Brinell Hardness: 170• Oil quench from 980 °C. Temper at 690 °C.

Tensile test at ambient temperature:

- UTS: 900 N/mm2

- 0.2 % Yield strength: 800 N/mm2

- Elongation (5d): 19 %

- Impact strength KCU: 150 J/cm2

Tensile test at 500 °C:

- UTS: 700 N/mm2

- 0.2 % Yield strength: 650 N/mm2

- Elongation (5d): 17 %

- Impact strength KCU: 110 J/cm2

Tensile test at 525 °C:

- UTS: 650 N/mm2

- 0.2 % Yield strength: 600 N/mm2

- Elongation (5d): 18 %

- Impact strength KCU: 110 J/cm2

Tensile test at 550 °C:

- UTS: 600 N/mm2

- 0.2 % Yield strength: 550 N/mm2

- Elongation (5d): 18.5 %

- Impact strength KCU: 110 J/cm2

We have following inspection equipment to inspect of all our 1.7709,21CrMoV5-7 forging steel gas steam turbine parts

a well equipped chemical lab which carries out test analysis on the steel heats made in the steel mill

a well equipped lab which carries out mechanical tensile & resilience tests as well as creep tests

a metallurgic lab for structural macro-micro and inclusion micro metallurgic examinations, according to ISO 17025

non destructive UT/MP/LP tests carried out by experienced and qualified SNT-TA-1A operators

fixed and portable Brinell/3000/10 hardness check equipment

dedicated and certified equipment for dimensional controls.

Welcome your inquiry of 21CrMoV5-7 forging forged steel parts