Description

Jiangsu Liangyi professional manufacturer of 2.4654, NC20K14,NiCr20Co13Mo4Ti3Al open die forging parts and seamless rolled steel forged rings from china

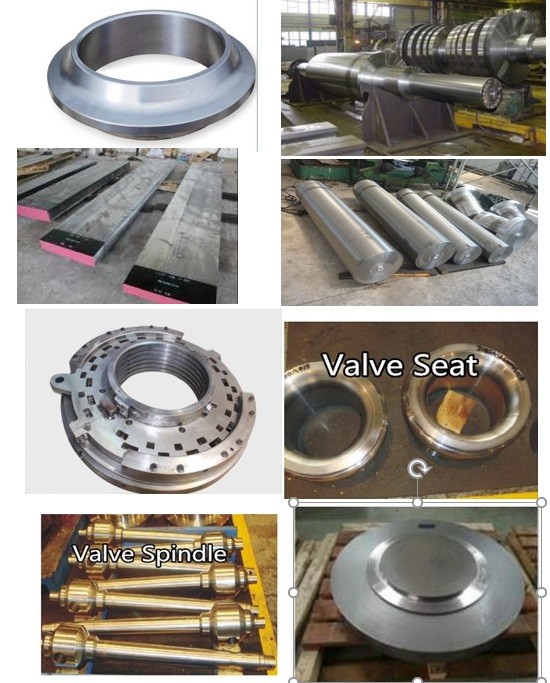

Following is the shape of 2.4654, NC20K14,NiCr20Co13Mo4Ti3Al forging steel material that we could do is:2.4654 Forged Steel round bars square bars Flat bars Rectangles Bars Rods,2.4654 Forged forging steel rings seamless rolled rings,2.4654 Forged Forging Steel Hubs housing shell Sleeves Bushes Bushing Cases Hollow Bars,NiCr20Co13Mo4Ti3Al Forged Forging Steel Discs Disks Blocks plates,NC20K14 Forged Forging Steel Pipe Tubes Tubings Piping Shells Casings Case barrels Housings.

Following is forging products of 2.4654, NC20K14,NiCr20Co13Mo4Ti3Al material that is used in following industry

2.4654 Forged Forging Gas Compressor Turbine Blades steel Flat Rectangles Bars

2.4654 Forged Forging Gas steam turbine disks, turbine impeller,turbine blisk,turbine discs

NC20K14 Forging Steel Forging Forged Gas Steam Turbine Doubled-headed Double end Studs Fasteners Bolts bolting

NiCr20Co13Mo4Ti3Al Forging Steel gas steam Turbine Guide Rings,seal rings Labyrinth Rings Packing Seal Diaphragm & Seal Ring Rotor End Rings contours Casing Rings

NC20K14 Forged Forging Steel Gas Steam turbine diaphragm diapharagm nozzles

2.4654 Forged Forging Gas Turbine LPT 1st & 2st 2nd Stg Stage Turbine Case Casings

2.4654 Forged Forging Steel power plant steam turbine control reheat valve disc Disk

NC20K14 Forged forging Gas Steam Turbine Valve Spindles/Stems/Rods,

NC20K14 Forging Steel Gas Steam Turbine MSV/GV/CV/CRV Valve Seats, Valve Cores, Valve Sleeves Spools,,Main Steam Valve Covers Bonnets Sleeves

2.4654 forged material for nuclear power such as :Flow limiter Venturi forgings (steam generator),Forged tubes for pressurizer surge line,reactor nozzles and primary pump fly wheels, divider plates for steam generator,Latch housings, rod travel housings and funnel extension,end ring and rotor stack plate forgings,bearing housings and stator end cap and closure ring forgings,Containment plates, rings and closure heads,Waste Flasks and Mounting Skirt,RPV Upper Shell and HSG Shell,Shell Strakes and Transition Cones,Pressure Components,Lifting Pin Tools and Trunnions,Pressuriser Upper Head and Upper Shell,Steam Drumhead and Lifting Pintles

2.4654 is a corrosion and heat resistant nickel alloy in the form of bars, forging and forging stock.

The alloy’s high-temperature strength is derived from its solid solution strengthening elements of molybdenum, cobalt, and chromium, and its age-hardening elements, aluminum and titanium. Its strength and stability ranges are higher than those typically available for Alloy 718.

2.4654 is widely used typically for rotating parts, such as compressor and gas turbine blades, disks, hubs, shafts bolts and spacers requiring high strength up to 1500°F (816°C) and oxidation resistance up to 1750°F (954°C) but usage is not limited to such applications.

The production standard of The 2.4654 forged material is as follows:

EN 10302: 2008 Creep resisting steels, nickel and cobalt alloys

The 2.4654 forged parts shall be free from defects such as cracks, flakes, seams, segregation, non-metallic inclusionsand other defects which may affect the utility of the forgings.

Chemical composition of 2.4654,NC20K14,NiCr20Co13Mo4Ti3Al forging turbine parts is as

Element Min Max

Nickel Balance Balance

Chromium 18.00 21.00

Cobalt 12.00 15.00

Titanium 2.75 3.25

Aluminum 1.20 1.60

Boron 0.003 0.01

Carbon 0.020 0.10

Zirconium 0.02 0.08

Iron 3.00 3.00

Manganese 0.10 0.10

Silicon 0.15 0.15

Phosphorous 0.015 0.015

Sulfur 0.015 0.015

mechanical property of for 2.4654,NC20K14,NiCr20Co13Mo4Ti3Al forged round bars is as follow

Rm - Tensile strength (MPa) (+P) 1100

Rp0.2 0.2% proof strength (MPa) (+P) 760

A - Min. elongation at fracture (%) (+P) 15-20

.

Our 2.4654,NC20K14,NiCr20Co13Mo4Ti3Alforged material is qualified in certificate of ISO 9001,ISO 14001.ISO 50001,ISO 3834-2, ISO 9712,ISO/IEC 17025,NORSOK M122,NORSOK M123

All our 2.4654,NC20K14,NiCr20Co13Mo4Ti3Al forged steel parts can be release in 10204-3.2 certificate by following third party DNV-GL BUREAU VERITAS,LLOYD’S REGISTER,ABS, RINA,TÜV

Welcome your inquiry of 2.4654,NC20K14,NiCr20Co13Mo4Ti3Al forging parts

Following is the shape of 2.4654, NC20K14,NiCr20Co13Mo4Ti3Al forging steel material that we could do is:2.4654 Forged Steel round bars square bars Flat bars Rectangles Bars Rods,2.4654 Forged forging steel rings seamless rolled rings,2.4654 Forged Forging Steel Hubs housing shell Sleeves Bushes Bushing Cases Hollow Bars,NiCr20Co13Mo4Ti3Al Forged Forging Steel Discs Disks Blocks plates,NC20K14 Forged Forging Steel Pipe Tubes Tubings Piping Shells Casings Case barrels Housings.

Following is forging products of 2.4654, NC20K14,NiCr20Co13Mo4Ti3Al material that is used in following industry

2.4654 Forged Forging Gas Compressor Turbine Blades steel Flat Rectangles Bars

2.4654 Forged Forging Gas steam turbine disks, turbine impeller,turbine blisk,turbine discs

NC20K14 Forging Steel Forging Forged Gas Steam Turbine Doubled-headed Double end Studs Fasteners Bolts bolting

NiCr20Co13Mo4Ti3Al Forging Steel gas steam Turbine Guide Rings,seal rings Labyrinth Rings Packing Seal Diaphragm & Seal Ring Rotor End Rings contours Casing Rings

NC20K14 Forged Forging Steel Gas Steam turbine diaphragm diapharagm nozzles

2.4654 Forged Forging Gas Turbine LPT 1st & 2st 2nd Stg Stage Turbine Case Casings

2.4654 Forged Forging Steel power plant steam turbine control reheat valve disc Disk

NC20K14 Forged forging Gas Steam Turbine Valve Spindles/Stems/Rods,

NC20K14 Forging Steel Gas Steam Turbine MSV/GV/CV/CRV Valve Seats, Valve Cores, Valve Sleeves Spools,,Main Steam Valve Covers Bonnets Sleeves

2.4654 forged material for nuclear power such as :Flow limiter Venturi forgings (steam generator),Forged tubes for pressurizer surge line,reactor nozzles and primary pump fly wheels, divider plates for steam generator,Latch housings, rod travel housings and funnel extension,end ring and rotor stack plate forgings,bearing housings and stator end cap and closure ring forgings,Containment plates, rings and closure heads,Waste Flasks and Mounting Skirt,RPV Upper Shell and HSG Shell,Shell Strakes and Transition Cones,Pressure Components,Lifting Pin Tools and Trunnions,Pressuriser Upper Head and Upper Shell,Steam Drumhead and Lifting Pintles

2.4654 is a corrosion and heat resistant nickel alloy in the form of bars, forging and forging stock.

The alloy’s high-temperature strength is derived from its solid solution strengthening elements of molybdenum, cobalt, and chromium, and its age-hardening elements, aluminum and titanium. Its strength and stability ranges are higher than those typically available for Alloy 718.

2.4654 is widely used typically for rotating parts, such as compressor and gas turbine blades, disks, hubs, shafts bolts and spacers requiring high strength up to 1500°F (816°C) and oxidation resistance up to 1750°F (954°C) but usage is not limited to such applications.

The production standard of The 2.4654 forged material is as follows:

EN 10302: 2008 Creep resisting steels, nickel and cobalt alloys

The 2.4654 forged parts shall be free from defects such as cracks, flakes, seams, segregation, non-metallic inclusionsand other defects which may affect the utility of the forgings.

Chemical composition of 2.4654,NC20K14,NiCr20Co13Mo4Ti3Al forging turbine parts is as

Element Min Max

Nickel Balance Balance

Chromium 18.00 21.00

Cobalt 12.00 15.00

Titanium 2.75 3.25

Aluminum 1.20 1.60

Boron 0.003 0.01

Carbon 0.020 0.10

Zirconium 0.02 0.08

Iron 3.00 3.00

Manganese 0.10 0.10

Silicon 0.15 0.15

Phosphorous 0.015 0.015

Sulfur 0.015 0.015

mechanical property of for 2.4654,NC20K14,NiCr20Co13Mo4Ti3Al forged round bars is as follow

Rm - Tensile strength (MPa) (+P) 1100

Rp0.2 0.2% proof strength (MPa) (+P) 760

A - Min. elongation at fracture (%) (+P) 15-20

.

Our 2.4654,NC20K14,NiCr20Co13Mo4Ti3Alforged material is qualified in certificate of ISO 9001,ISO 14001.ISO 50001,ISO 3834-2, ISO 9712,ISO/IEC 17025,NORSOK M122,NORSOK M123

All our 2.4654,NC20K14,NiCr20Co13Mo4Ti3Al forged steel parts can be release in 10204-3.2 certificate by following third party DNV-GL BUREAU VERITAS,LLOYD’S REGISTER,ABS, RINA,TÜV

Welcome your inquiry of 2.4654,NC20K14,NiCr20Co13Mo4Ti3Al forging parts