Description

Jiangsu Liangyi is professional manufacturer of AMS 6512 open die forging parts and seamless rolled steel forged rings from china

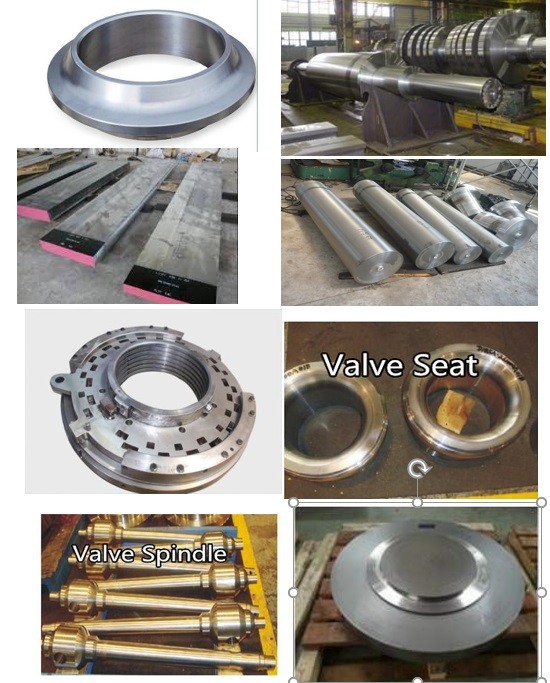

Following is the shape of AMS 6512 forging steel material that we could do is: AMS 6512 Forged Steel round bars square bars Flat bars Rectangles Bars Rods,AMS 6512 Forged forging steel rings seamless rolled rings,AMS 6512 Forged Forging Steel Hubs housing shell Sleeves Bushes Bushing Cases Hollow Bars,AMS 6512 Forged Forging Steel Discs Disks Blocks plates,AMS 6512 Forged Forging Steel Pipe Tubes Tubings Piping Shells Casings Case barrels Housings.

Following is forging products of AMS 6512 material that is used in following industry

AMS 6512 Forged Forging Turbine and Compressor Labyrinth Shaft Seals

AMS 6512 Forged Forging Valve Balls,valve Bonnets,valve Body Bodies ,valve Stems,valve closures, valve seat rings, valve core, valve discs,for H type two way 2‐way one way back pressure valves, ball valve,check valve,gate valve

AMS 6512 Forged Forging Steel nuclear Power reactor coolant pumps Rotor Impellers

AMS 6512 Forged Forging Steel Butterfly Valve Main Shafts Spindles

AMS 6512 Forged Forging downhole drilling tool Mud Motor Splined Drive shafts,Down hole Electric electrical submersible pumps ESP motor Splined Shaft

AMS 6512 Forged Forging Gas Air Compressor Rotor

AMS 6512 Forged Forging venturi cone meter Body Bodies Blocks

AMS 6512 Forged Forging Steel gate valves Body Bodies bespoke flat bars

AMS 6512 forged steel Flowseal cryogenic High Performance BV Butterfly Valves HPBV shaft

AMS 6512 forging steel Oil measurement valve Spool Ultrasonic flow meter bodies Body

AMS 6512 Forged Forging Steel double studded adapter flange

AMS 6512 Forged Forgig Steel nuclear reactor coolant pump Casing Shells body bodis blocks,nuclear reactor coolant pumps containment seal chamber Rooms,nuclear reactor coolant pumps containment seal chamber Rooms

AMS 6512 Forged Forging turbomachinery turbo centrifugal compressor Impeller,Compressor Shrouded Impellers

AMS 6512 Forged Forging Steel Forged Single Double Bossed boss Blanks FLANGED BOSSES

AMS 6512 Forged Forging Steel PUMP Casing cover.PUMP BARREL,pump impeller,pump shafts, pump housing, pump shells,pump body,pump wear rings,pump case casing.

AMS 6512 Forged Forging forge Steel transition Cone

AMS 6512 Forged Forging Steel Pressure Vessel Reactor Nozzles

AMS 6512 Forged Forging Gas Compressor Turbine Blades steel Flat Rectangles Bars

AMS 6512 Forged Forging Gas steam turbine disks, turbine impeller,turbine blisk,turbine discs,turbine wheel discs

AMS 6512 Forging Steel Forging Forged Gas Steam Turbine Doubled-headed Double end Studs Fasteners Bolts bolting

AMS 6512 Forging Steel gas steam Turbine Guide Rings,seal rings Labyrinth Rings Packing Seal Diaphragm & Seal Ring Rotor End Rings contours Casing Rings

AMS 6512 Forged Forging Steel Gas Steam turbine diaphragm diapharagm nozzles

AMS 6512 Forged Forging Gas Turbine LPT 1st & 2st 2nd Stg Stage Turbine Case Casings

AMS 6512 Forged Forging Steel power plant steam turbine control reheat valve disc Disk

AMS 6512 Forged forging Gas Steam Turbine Valve Spindles/Stems/Rods,

AMS 6512 Forging Steel Gas Steam Turbine MSV/GV/CV/CRV Valve Seats, Valve Cores, Valve Sleeves Spools,,Main Steam Valve Covers Bonnets Sleeves

AMS 6512 forged forging steel pipes tubes shells piping tubing barrels housing, tube sheets,baffle plates, nozzles, channel flanges for boiler, heat exchanger,pressure vessel,reactors, heaters

AMS 6512 is a an 18% nickel, cobalt strengthened steel (C-type) with excellent properties, workability and heat treatment characteristics. AMS 6512 is double vacuum melted by VIM (Vacuum Induction Melt) followed by VAR (Vacuum Arc Remelt). Maraging material is supplied in the annealed and descaled condition. The alloy is very tough, relatively soft (RC 30/35), readily machined or formed. Maraging provides a high value for critical parts in aerospace, structural, component and tooling applications.

FOllowing is chemical compostion of AMS 6512 forged steel rings

Carbon 0.03 % Max

Manganese 0.10 % Max

Phosphorus 0.010 % Max

Sulfur 0.010 % Max

Silicon 0.10 % Max

Nickel 17.00 – 19.00 %

Cobalt 7.00 – 8.50 %

Molybdenum 4.60 – 5.20 %

Titanium 0.30 – 0.50 %

Aluminum 0.05 – 0.15 %

Iron Balance

Following of AMS 6512 forging parts heat treatment nechanical property Delivery condition :

Tensile Strength ……… 255,000 psi Minimum

Yield Strength ………… 250,000 psi Minimum

Elongation …………….. 6 % Minimum

Reduction of Area ….. 45 % Minimum

The quality of Jiangsu products AMS 6512 forging workshop is based on its “state-of-the-art”technology of its laboratories for metallurgy and chemistry. we perform a range of tests, including mechanical property tests, chemical and environmental analyses, metallographic, macrographic and micrographic tests using optical and electronic microscopes. , all AMS 6512 forging shafts materials are tested and certified in accordance with nternational standards and Customer’s specifications, using any combination of the following methods: UT-RT-HT-PT-MT-VT-DT

The following requirements of AMS 6512 forged parts are acceptance tests and shall be performed on each heat or lot as applicable.

Composition of each heat.

Hardness and average grain size of each lot of bars, forgings, and forged rings as solution heat treated.

Room-temperature tensile properties , hardness , and stress-rupture properties (of each lot of bars, forgings, and forged rings after precipitation heat

treatment.

Microstructure of each lot.

Periodic Tests: The following requirements are periodic tests and shall be performed at a frequency selected by the vendor unless frequency of testing is specified by purchaser:

Tensile Properties

hardness and stress-rupture properties of AMS 6512 forged parts after resolution and precipitation heat treatment

Grain flow of AMS 6512 forgings

Welcome your inquiry of AMS 6512 forging forged steel parts