Description

Jiangsu Liangyi is professional manufacturer of Inconel 783,UNS R30783,,Alloy 783,Inconel ALloy 783 open die forging parts and seamless rolled steel forged rings from china

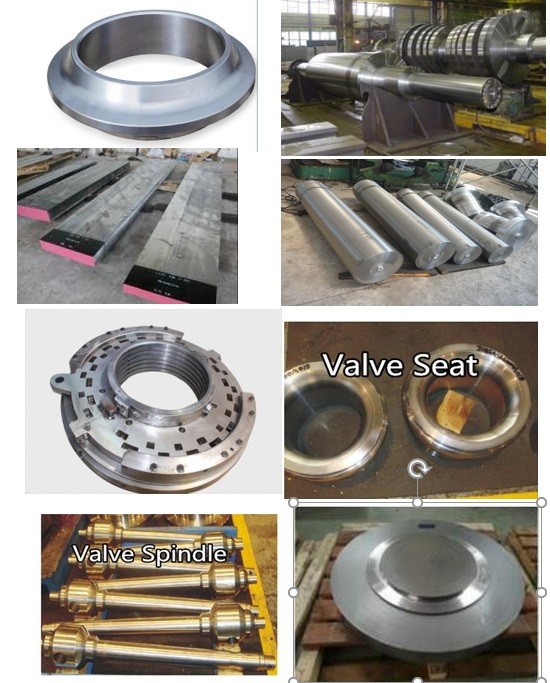

Following is the shape of Inconel 783,Inconel ALloy 783, Alloy 783,UNS R30783 forging steel material that we could do is:Inconel 783 Forged Steel round bars square bars Flat bars Rectangles Bars Rods,Inconel ALloy 783 Forged forging steel rings seamless rolled rings,Alloy 783 Forged Forging Steel Hubs housing shell Sleeves Bushes Bushing Cases Hollow Bars,UNS R30783 Forged Forging Steel Discs Disks Blocks plates,Inconel 783 Forged Forging Steel Pipe Tubes Tubings Piping Shells Casings Case barrels Housings.

Following is forging products of Inconel 783,Inconel ALloy 783, Alloy 783,UNS R30783 material that is used in following industry

Inconel 783 Forged Forging Valve Balls,valve Bonnets,valve Body Bodies ,valve Stems,valve closures, valve seat rings, valve core, valve discs,for H type two way 2‐way one way back pressure valves, ball valve,check valve,gate valve

Inconel Alloy 783 Forged Forging turbomachinery turbo centrifugal compressor Impeller,Compressor Shrouded Impellers

Inconel Alloy 783 Forged Forging Steel PUMP Casing cover.PUMP BARREL,pump impeller,pump shafts, pump housing, pump shells,pump body,pump wear rings,pump case casing.

Alloy 783 Forged Forging forge Steel transition Cone

UNS R30783 Forged Forging Steel Pressure Vessel Reactor Nozzles

Alloy 783 Forged Forging Gas Compressor Turbine Blades steel Flat Rectangles Bars

Alloy 783 Forged Forging Gas steam turbine disks, turbine impeller,turbine blisk,turbine discs,turbine wheel discs

Inconel Alloy 783 Forging Steel Forging Forged Gas Steam Turbine Doubled-headed Double end Studs Fasteners Bolts bolting

Inconel Alloy 783 Forging Steel gas steam Turbine Guide Rings,seal rings Labyrinth Rings Packing Seal Diaphragm & Seal Ring Rotor End Rings contours Casing Rings

Inconel Alloy 783 Forged Forging Steel Gas Steam turbine diaphragm diapharagm nozzles

Inconel 783 Forged Forging Gas Turbine LPT 1st & 2st 2nd Stg Stage Turbine Case Casings

Inconel 783 Forged Forging Steel power plant steam turbine control reheat valve disc Disk

UNS R30783 Forged forging Gas Steam Turbine Valve Spindles/Stems/Rods,

Inconel 783 Forging Steel Gas Steam Turbine MSV/GV/CV/CRV Valve Seats, Valve Cores, Valve Sleeves Spools,,Main Steam Valve Covers Bonnets Sleeves

Inconel 783 forged forging steel pipes tubes shells piping tubing barrels housing, tube sheets,baffle plates, nozzles, channel flanges for boiler, heat

INCONEL alloy 783 is an oxidation-resistant, low expansion, nickel-cobalt-iron alloy with aluminum, chromium, and niobium additions. The alloy is of considerable interest to aircraft gas turbine engine designers and materials engineers for containment and clearance control components such as rings, casings, shrouds and seals for compressors, turbines and exhaust systems.

FOllowing is chemical compostion of Inconel ALloy 783 forged steel rings

Nickel, Ni 26-30

Iron, Fe 24-27

Aluminum, Al 5-6

Chromium, Cr 2.5-3.5

Niobium, Nb 2.5-3.5

Copper, Cu 0.50 max

Manganese, Mn 0.50 max

Silicon, Si 0.50 max

Titanium, Ti 0.10-0.40

Carbon, C 0.03 max

Boron, B 0.003-0.012

Phosphorus, P 0.015 max

Sulfur, S 0.005 max

Cobalt, Co Balance

Solution Heat Treatment

Inconel 783 forge material shall be solution heat treated by heating to a temperature within the range 2025 to 2050 °F (1107 to 1121 °C), holding at the selected temperature within ±25 °F (±14 °C) for a time commensurate with section thickness, and cooling at a rate equivalent to an air cool or faster

If forgings are not to be machined all over, heat treatment shall be performed in a suitable protective atmosphere or, when permitted by purchaser, a suitable protective coating may be applied to the forgings in lieu of using a protective atmosphere.

Solution Heat Treatment of inconel 783 forged bars Shall be not higher than 29 HRC, or equivalent , determined in accordance with ASTM E 18. Average Grain Size:Shall be as follows, determined by the comparative method of ASTM E 112. In case of disagreement, the intercept (Heyn) procedure shall be used.

Inconel 783 forged Bars and rings under 9 square inches (58 cm2) in cross-sectional area shall exhibit averagegrain size of ASTM No. 5 or finer. Areas of nonrecrystallized grains with an average grain size, determined

by the intercept method, of ASTM No. 3 to 5 are permitted but shall not account for more than 20% of the cross-section.

Inconel 783 forged Bars and rings 9 to 50 square inches (58 to 323 cm2), inclusive, in cross-sectional area and all forgings shall exhibit average grain size of ASTM No. 4 or finer. Areas of non recrystallized grains with an

average grain size, determined by the intercept method, of ASTM No. 2 to 4 are permitted but shall not account for more than 20% of the cross-section." Limitations on duplex grain structures as defined by ASTM E 1181 shall be as agreed upon by purchaser and vendor.

The product of Inconel 783 forged parts shall have the following properties after being precipitation heat treated by heating to 1550 °F ± 15 (843 °C ± 8), holding at heat for 2 to 4 hours, cooling at a rate equivalent to an air cool to room temperature, heating to 1325 °F ± 15 (718 °C ± 8), holding atheat for 8 hours ± 0.5, cooling at a rate of approximately 100 °F (56 °C) degrees per hour to 1150 °F ± 15 (621 °C ± 8), holding at 1150 °F ± 15 (621 °C ± 8) for 8 hours ± 0.5, and cooling at a rate equivalent to an air cool

Stress-Rupture Properties at 1200 °F (649 °C) of inconel 783 forged material Shall be as follows; testing of notched specimens and of combination smooth-and-notched specimens shall be performed in accordance with ASTM E 292 and testing of smooth specimens shall be performed in accordance with ASTM E 139

A standard cylindrical combination smooth-and-notched specimen conforming to ASTM E 292, maintained at 1200 °F ± 3 (649 °C ± 2) while a load sufficient to produce an initial axial stress of 85.0 ksi (586 MPa) or

higher is applied continuously, shall not rupture in less than 23 hours. The test shall be continued to rupture without change of load. Rupture shall occur in the smooth section and elongation of this section after

rupture, measured at room temperature, shall be not less than 8% in 4D for product 5.0 inches (127 mm) and under in nominal diameter or least distance between parallel sides and shall be reported for product

over 5.0 inches (127 mm) in nominal diameter and least distance between parallel sides.

As an alternate procedure, separate smooth and notched specimens, machined from adjacent sections of the same piece, with gage sections conforming to the respective dimensions shown in ASTM E 292, may be

tested individually . The smooth specimen shall not rupture in less than 23 hours and elongation after rupture, measure at room temperature, shall be as specified.

The notched specimen shall not rupture in less time than the companion smooth specimen but need not be tested to rupture.

The tests may be conducted using incremental loading. In such case, the load required to produce an initial axial stress of 85.0 ksi (586 MPa) or higher shall be used to rupture or for 23 hours, whichever occurs first. After the 23 hours and at intervals of 8 hours minimum thereafter, the stress shall be increased in increments of 5.0 ksi (34.5 MPa). Time to rupture, rupture location, and elongation requirements shall be as specified

Mean Coefficient of Linear Expansion: Shall not exceed 7.5 x 10-6 inch/inch/。F (13.5 x 10-6 mm/mm/°C) at 1200 °F (649 °C) using 77 °F (25 °C) as the reference temperature, determined in accordance with ASTM E 228.

Following of Inconel 783 forging parts heat treatment mechanical property Delivery condition in room temperature

Properties Metric Imperial

Tensile strength 1194 MPa 171 ksi

Yield strength 779 MPa 113 ksi

Poisson’s ratio 0.31 0.31

Elastic modulus 177.3 GPA 25.72 ksi

Elongation at break 24% 24%

| At 1200 °F (649 °C) mechanical property test | |||||||||||||||||

| , determined in accordance with ASTM E 21 on specimens heated to 1200 °F ± 5 | |||||||||||||||||

| (649 °C ± 3), held atheat for not less than 20 minutes before testing, and tested at 1200 °F ± 5 (649 °C ± 3). | |||||||||||||||||

| TABLE 3 - MINIMUM 1200 。F (649 。C) TENSILE PROPERTIES | |||||||||||||||||

| Property | Value | ||||||||||||||||

| Tensile Strength | 130 ksi (896 MPa) | ||||||||||||||||

| Yield Strength at 0.2% Offset | 90 ksi (621 MPa) | ||||||||||||||||

| Elongation in 4D | 15% | ||||||||||||||||

| Reduction of Area | 25% | ||||||||||||||||

FOllowing is inspection standard of inconel 783 forged parts:

ASTM E 8 Tension Testing of Metallic Materials

ASTM E 8M Tension Testing of Metallic Materials (Metric)

ASTM E 10 Brinell Hardness of Metallic Materials

ASTM E 354 Chemical Analysis of High-Temperature,Electrical,Magnetic,and Other Similar Iron,Nickel,and Cobalt Alloys

The following test methods of inconel 783 forged rings shall be used during delivery inspection.

Tensile testing:EN ISO 6892-1.

Creep rupture testing:ISO 204.

UItrasonic testing shall be carried out in accordance with agreed testing procedure specification.

Macroetching:ASTM A604.

Grain size estimation:ASTM E112

MARKING of our finished forged inconel 783 bars

Each part shall be stamped with:

The purchaser's part number

The purchaser's purchase number

The individual number

The heat number,if traceability to heat number is not possible by the individual number

The marking shall be surrounded by a frame or painted over with white durable paint.

Welcome your inquiry of Inconel 783,Inconel ALloy 783, Alloy 783,UNS R30783) forging forged steel parts