Description

Jiangsu Liangyi professional manufacturer of 1.4938, X12CrNiMoV12-3,X12CrNiMoV12.3,X12CrNiMoV123,X 12 CrNiMoV 12-3 open die forging parts and seamless rolled steel forged rings from china

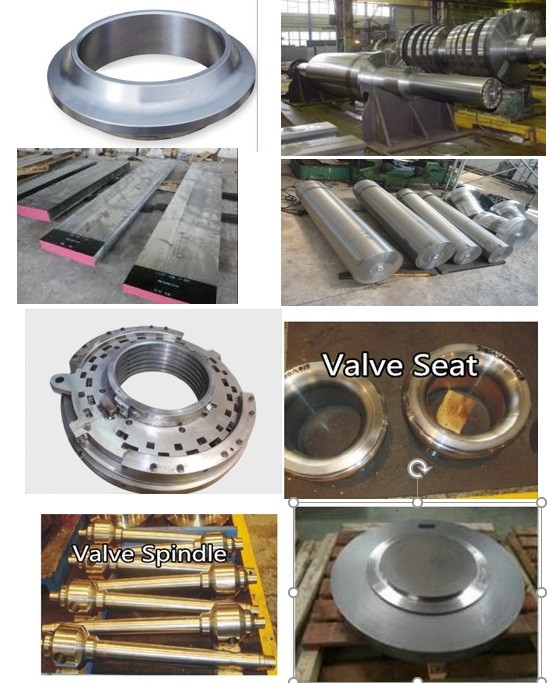

Following is the shape of 1.4938, X12CrNiMoV12-3,X12CrNiMoV12.3,X12CrNiMoV123,X 12 CrNiMoV 12-3 Forging steel material that we could do is:1.4938 Forged Steel round bars square bars Flat bars Rectangles Bars Rods, X12CrNiMoV12-3 Forged forging steel rings seamless rolled rings, X12CrNiMoV12.3 Forged Forging Steel Hubs housing shell Sleeves Bushes Bushing Cases Hollow Bars, X12CrNiMoV123 Forged Forging Steel Discs Disks Blocks plates, X12CrNiMoV12-3 Forged Forging Steel Pipe Tubes Tubings Piping Shells Casings Case barrels Housings. X12CrNiMoV12-3 Forged Forging Steel Gas Steam Turbine Rotors Shafts Turbine Blades turbine impeller, turbine disks turbine blisks Turbine Guide Rings,seal rings Labyrinth Rings Packing Seal Diaphragm & Seal Ring Rotor End Rings contours Casing Rings turbine bolts

Our 1.4938, X12CrNiMoV12-3 forged steel parts is normal melting by Basic Electric Furnace (EAF, AOD, VOD) or + Electroslag remelting. (ESR) AS PER CLIENTS NEEDS

For melting X12CrNiMoV12-3 (1.4938) forging steel material, we have following melting equipment

60 t Electric Arc Furnace (EAF) / Power 40 MVA

2 Ladle Furnace (LF)

2 Tank Degassing VD - VOD type

Pits for bottom pouring

ESR Plant (max weight 32 t)

Chemical composition % of steel X12CrNiMoV12-3 (1.4938) forged steel round bars: EN 10302-2008

C 0.08 - 0.15

Si max 0.5

Mn 0.4 - 0.9

Ni 2 - 3

P max 0.025

S max 0.015

Cr 11 - 12.5

Mo 1.5 - 2

V 0.25 - 0.4

N 0.02 - 0.04

Mechanical properties of steel X12CrNiMoV12-3 (1.4938) forging steel rings

Rm - Tensile strength (MPa) (+QT) 930-1130

Rp0.2 0.2% proof strength (MPa) (+QT) Minimum 760

KV - Impact energy (J) (+QT) +20° Minimum 40J

A - Min. elongation at fracture (%) (+QT) Minimum 14

Z - Reduction in cross section on fracture (%) (+QT) Minimum 40

X12CrNiMoV12-3 is a high-alloy chromium-nickel-molybdenum steel with the addition of vanadium for carburization with a martensitic structure, which due to high strength properties and significantly increased resistance to oxidation, is widely used in steam generators and steam turbines for their excellent high temperature properties and creep resistance, up to 650°C the production of aviation propellers, especially loaded gears, ball screws, responsible parts working at elevated temperatures such as rotors and turbine blades, bolts in the power industry, pump components as well as coupling parts in aircraft constructions.

Our X12CrNiMoV12-3 (1.4938) turbine rotor shafts and turbine blade is qualified in certificate of ISO 9001,ISO 14001.ISO 50001,ISO 3834-2, ISO 9712,ISO/IEC 17025,NORSOK M122,NORSOK M123

All our X12CrNiMoV12-3 forged steel turbine parts can be release in 10204-3.2 certificate by following third party DNV-GL BUREAU VERITAS,LLOYD’S REGISTER,ABS, RINA,TÜV