Description

Jiangsu Liangyi professional manufacturer of ASTM A182-F92,ASME SA182 F92,ASME SA336 F92 ,ASME SA336 P92,A 335 Grade P92 - SA 355 Grade P92 , ASTM A 182 F 92 open die forging parts and seamless rolled steel forged rings, sleeves,forged pipes tubes,forging steel valve body valve closure valve stems valve bonnet valve body valve seat rings from china

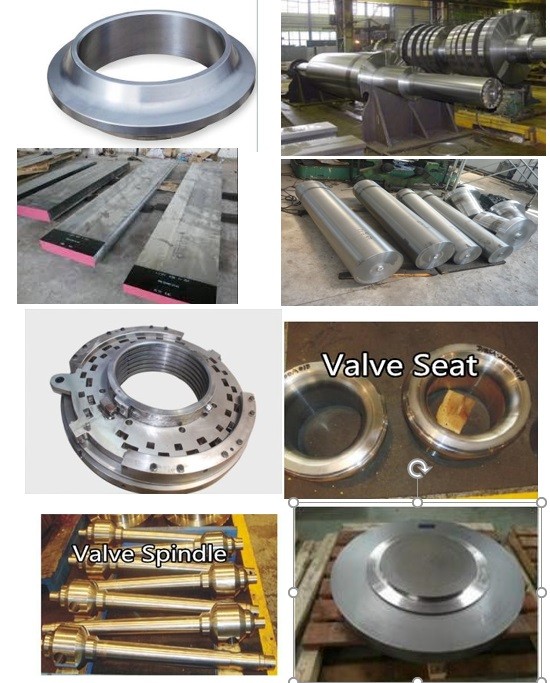

Following is the shape of ASTM A182-F92,ASME SA182 F92,ASME SA336 F92 ,ASME SA336 P92 forging steel material that we could do is:ASTM A182-F92 Forged Steel round bars square bars Flat bars Rectangles Bars Rods,ASME SA182 F92 Forged forging steel rings seamless rolled rings,ASME SA336 F92 Forged Forging Steel Hubs housing shell Sleeves Bushes Bushing Cases Hollow Bars,ASME SA336 P92 Forged Forging Steel Discs Disks Blocks plates,ASTM A 182-F92 Forged Forging Steel Pipe Tubes Tubings Piping Shells Casings Case barrels Housings.

Following is forging products of ASTM A182-F92 that is used in following industry

ASTM A182-F92, Forginbg forged steel valve body,valve bonnet.valve closure, valve seat rings, valve stems, valve discs disks for High pressure gate valves,High pressure globe valves, High Pressure Swing Check valve,High pressure valves steam turbine power valves, GAs TURBINE BYPASS VALVE,Line blind valves,Preheater bypass valve

ASME SA182 F92 forged forging steel pipes tubes shells piping tubing barrels housing, tube sheets, nozzles, channel flanges for boiler, heat exchanger,pressure vessel

ASME SA336 F92 Forged Forging Gas Compressor Turbine Blades steel Flat Rectangles Bars

ASME SA336 P92 Forging Forged Steel Gas Turbine Wheels Discs turbine impeller turbine blisks

F92 Forging Steel Gas Steam Turbine MSV/GV/CV/CRV Valve Seats, Valve Cores, Valve Sleeves Spools,,Main Steam Valve Covers Bonnets Sleeves

A182-F92 is is a high-temperaturemartensitic steel from the group of 9%Cr content steels used for forged pipes up to 620 °C. Itwas produced by modification and optimisation of the chemical

composition of P92 steel, mainly by adding 1.8% tungsten as well as niobium, boron and nitrogen microadditions, and by reduction in molybdenum content down to 0.6% . This steelhas filled the gap between the materials for service at elevatedtemperature under subcritical load conditions and the alloys that may transfer supercritical and ultra-supercritical loadconditions . It is characterised by a number of significant

features, including, but not limited to, good strength properties,corrosion resistance, weldability and heat resistance at elevatedtemperature, and much higher, by approx. 20%, creep strength compared to the X10CrMoVNb9-1 (T/P92) steel.

FOllowing is normal name for F92 forging steel parts:

A 336 GRADE F92, SA 336 GRADE F92, A 336 GRADE F921, SA 336 GRADE F921, A 336 GRADE FP92, A 387 GRADE 92, SA 387 GRADE 92, A182 F92, A200 T92, A182 F921, SA182 F921, SA335 GRADE P921, A335 GRADE P92, A692 GRADE 92, SA335 GRADE P92.

FOllowing is melting methods of ASME SA336 F92 forged steel parts:

BEF / BEF + AOD / EAF, followed by electroslag refining (ESR or VAR ) if necessary for special purpose.

FOllowing is chemical compostion of ASME SA182 F92 forging pipes

Element Composition, %

Carbon 0.07-0.13

Manganese 0.30-0.60

Phosphorous 0.020 max

Sulfur 0.010 max

Silicon 0.50 max

Chromium 8.50-9.50

Molybdenum 0.30-0.60

Tungsten 1.50-2.00

Nickel 0.40 max

Vanadium 0.15-0.25

Niobium 0.04-0.09

Nitrogen 0.03-0.070

Aluminum* 0.02 max

Boron 0.001-0.006

Titanium 0.01 max

Zirconium 0.01 max

Folllowing is mechanical property of ASME SA182 F92 forging steel tubes

Tensile strength, σb/≥ MPa: 620

Yield strength, σ0.2/MPa: 440

Elongation, δ ≥(%): 20.0

Reduction of area, ф ≥ (%): 45.0

Hardness via heat treatment /HBW: 250 Max.

FOllowing is heat treat way for ASME SA182 F92 forged steel parts

Condition: Solution annealed 1040 ~ 1080 Deg. C

Cooling medium: air cool

Tempering temperature: 730 ~ 800 Deg. C

In order to make forging and make heat treatment A182-F92 forging steel parts, we have following production equipment

Forging Process:3200/4200/6000 t Open die presses

Manipulators, Lifting Capacity up to 60 t

Heating Forging Furnaces, Max Capacity 150 t

Furnaces for Hydrogen Bake-Out Up to 14 m

Heat Treatment Semi-automatic Heat Treatment System Quality Heat Treatment

Furnaces Max lenght 18 m Quenching tanks up to 16 m

Also we have following machining equipment of rough machined F92 forged steel material

Rough & Finishing Machining, Vertical Lathes,Parallel Lathes,Extra Large Parallel Lathes, NC Boring Machines, Milling, Planning Machine, Column Drill

Our A182-F92 forging steel parts is qualified in certificate of ISO 9001,ISO 14001.ISO 50001,ISO 3834-2, ISO 9712,ISO/IEC 17025,NORSOK M122,NORSOK M123

All our ASME SA182 F92 forged steel pipes can be release in 10204-3.2 certificate by following third party DNV-GL BUREAU VERITAS,LLOYD’S REGISTER,ABS, RINA,TÜV

Welcome your inquiry of ASTM A182-F92,ASME SA182 F92 forging forged steel parts