Description

Jiangsu Liangyi professional manufacturer of 1.4906,12CrMoWVNbN1011, X12CrMoWVNbV10-1-1,X 12 CrMoWVNbN 1011 open die forging parts and forged steel gas steam turbine generator rotor shafts, turbine blade vane steel factory from china

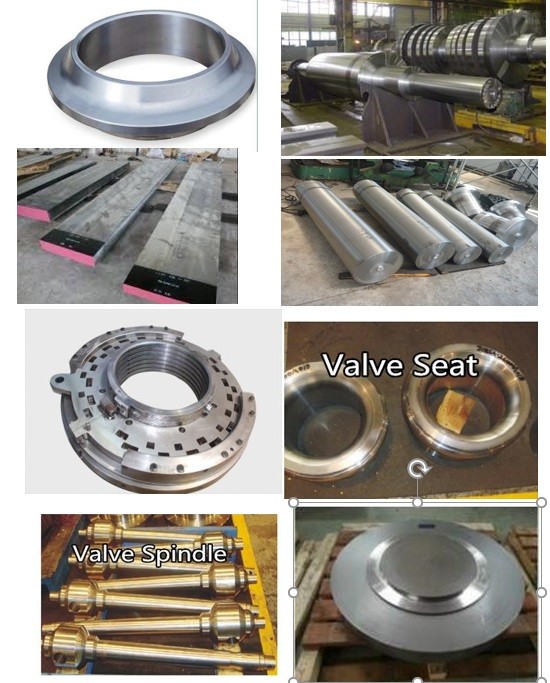

Following is the shape of 1.4906,12CrMoWVNbN1011, X12CrMoWVNbV10-1-1,X 12 CrMoWVNbN 1011 Forging steel material that we could do is:12CrMoWVNbN1011 Forged Steel round bars square bars Flat bars Rectangles Bars Rods, X12CrMoWVNbV10-1-1 Forged forging steel rings seamless rolled rings, 1.4906 Forged Forging Steel Hubs housing shell Sleeves Bushes Bushing Cases Hollow Bars,X 12 CrMoWVNbN 1011 Forged Forging Steel Discs Disks Blocks plates, 1.4906 Forged Forging Steel Pipe Tubes Tubings Piping Shells Casings Case barrels Housings. 12CrMoWVNbN1011 Forged Forging Steel Gas Steam Turbine Rotors Shafts,X12CrMoWVNbV10-1-1 Forged Forging Gas Compressor Turbine Blades turbine Vane steel Flat Rectangles Bars, 12CrMoWVNbN1011 Forged Forging Steel gas steam Turbine Guide Rings,seal rings Labyrinth Rings Packing Seal Diaphragm & Seal Ring Rotor End Rings contours Casing Rings,,X 12 CrMoWVNbN 1011 Forged forging Gas Steam Turbine Valve Spindles/Stems/Rods,1.4906 Forging Forged Gas Steam Turbine Doubled-headed Double end Studs Fasteners Bolts

Chemical composition for X12CrMoWVNbV10-1-1 forged steel gas turbine blade steel

Heat analysis in weight %

C:0.11-0.13

Si≤0.12

Mn:0.40-0.50

P:≤0.010

S:≤0.005

Cr:10.2-10.6

Mo:1.00-1.10

Ni:0.70-0.80

W:0.95-1.05

V:0.15-0.25

AL:≤0.010

N:0.045-0.060

Nb:0.040-0.060

Heat Treatment of X12CrMoWVNbV10-1-1 forging steel parts is as follows:

12CrMoWVNbN1011 forging turbine rotor shafts shall be delivered in quenched and tempered condition.At the whole cross section a completely converted martensite structure must be achieved.A regular grain size as per ASTM E 112 from>3.0 is to be achieved

Hardening:1070-1100°℃/air or liquid quenching

Tempering:at least 2 times

Level 1:T1=570℃/4h/air or liquid

Level 2:T2≥700℃

Minimal residual stresses shall be achieved by selecting sufficient tempering times and slow cooling rates after tempering

If it is necessary to straighten 1.4906 forging flat bars after the heat treatment,stress relief annealing is mandatory afte completion of the overall straightening process.Stress relief annealing shall be performed at 30 K below the tempering temperature and with a slow cooling rate.

The mechanical properties of 12CrMoWVNbN1011 forging steam gas turbine blade Steel shall be determined after all heat treatment steps are finished (including a possible stress relieving).They shall be determined on the hardest and softest bar per melt and heat treatment batch.If the cross section are >200cm²then themechanical properties must be determined both in the centre of the X12CrMoWVNbV10-1-1 forged flat bar and at the side of the bar .It shall be ensured that the required mechanical properties are achieved throughout the entire bar cross section.With the exception of toughness,the difference in properties across the bar cross section shall not exceed 5%.Tensile testing shall be conducted according to EN 10002 resp.ASTM E8M (round tension test specimen with Lo=50 mm and do=10 mm)or ASTM E8.Impact testing shall be performed with standard test pieces with V-notch according to EN 10045

The following properties of 12CrMoWVNbN1011 forging turbine blade flat bars at room temperature must be demonstrated by the following tests

0.2 %Yield strength (N/mm² 750-830

Tensile Strength (N/mm²) 870-970

Elong.(lo =5d ≥14

R A(% ≥55

Impact energy (J ≥50

Hardness(HB 270-310

Average of 3 12CrMoWVNbN1011 forging steel specimens and minimum value for two specimens per EN 10021,where the owest value shall be at least 35 J

The uniformity of the strength of the X12CrMoWVNbV10-1-1 forged steel turbine rotor shafts of a given delivery(per melt and heat treatmen batch =test unit)shall be verified by a hardness test per ISO 6506 -1.Hardness tests are to be performed after all heat treatments(including a possible stress relieving)are undertaken.HBW 10/3000 or HBW 5/750 shall be used.

The purity grade of the X12CrMoWVNbV10-1-1 forged gas turbine discs material is to be determined per DIN 50602-K1.The following value is to be kept in this case(on 1000 mm²)-Sum characteristics value K1:≤2.0

For determination 4 tests per heat are to be employed at least Depending on the appearance of the analysed microsections also higher K1-Values may possibly be Tolerated.Content of Delta-Ferrite Delta ferrite content:<5% (Determined in a manner consistent with the evaluation technique described in ASTM E 45/Method A,"Worst Field Method"at V=100,specimen orientation:longitudinal.Thedistribution and size of delta ferrite must be such that it does not result in indication in magnetic particle testing of the ready-machined surface.)

The following NDT inspections shall be performed after all heat treatments are performed

Visual inspection of all 1.4906 forging round bars

UT of all X 12 CrMoWVNbN 1011 flat bars as per SEP 1923,inspection number D3 or D2 with dual (twin crystal search unit.100% of the volume shall be examined with the stipulated ecording level

Criteria stipulated in SEP 1923 quality class 2 b shall be applied with following modification:EE(single echo)and VE(numerous single echoes)without extension ≥2mm KSR are not permitted Defects above the recording limit shall be marked and it shall be ensured that these 1.4906 forging flat bars are not included in the lot delivered.