Description

Jiangsu Liangyi is professional manufacturer of AMS 5726,AMS 5731,AMS 5732,AMS 5734,AMS 5737,AMS 5853,AMS 5895 open die forging parts and seamless rolled steel forged rings from china

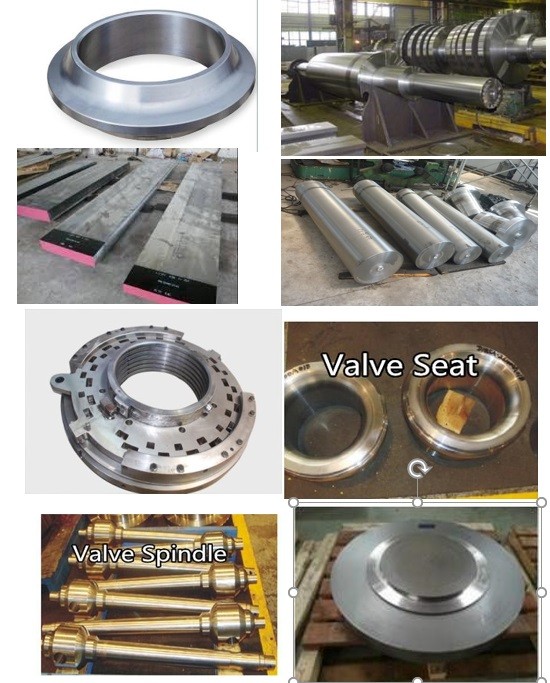

Following is the shape of AMS 5726,AMS 5731,AMS 5732,AMS 5734,AMS 5737,AMS 5853,AMS 5895 forging steel material that we could do is:AMS 5726,AMS 5731,AMS 5732,AMS 5734,AMS 5737,AMS 5853,AMS 5895 Forged Steel round bars square bars Flat bars Rectangles Bars Rods,AMS 5726,AMS 5731,AMS 5732,AMS 5734,AMS 5737,AMS 5853,AMS 5895 Forged forging steel rings seamless rolled rings,AMS 5726,AMS 5731,AMS 5732,AMS 5734,AMS 5737,AMS 5853,AMS 5895 Forged Forging Steel Hubs housing shell Sleeves Bushes Bushing Cases Hollow Bars,AMS 5726,AMS 5731,AMS 5732,AMS 5734,AMS 5737,AMS 5853,AMS 5895 Forged Forging Steel Discs Disks Blocks plates,AMS 5726,AMS 5731,AMS 5732,AMS 5734,AMS 5737,AMS 5853,AMS 5895 Forged Forging Steel Pipe Tubes Tubings Piping Shells Casings Case barrels Housings.

Following is forging products of AMS 5726,AMS 5731,AMS 5732,AMS 5734,AMS 5737,AMS 5853,AMS 5895 material that is used in following industry

AMS 5726,AMS 5731,AMS 5732,AMS 5734,AMS 5737,AMS 5853,AMS 5895 Forged Forging Turbine and Compressor Labyrinth Shaft Seals

AMS 5726,AMS 5731,AMS 5732,AMS 5734,AMS 5737,AMS 5853,AMS 5895forged forging Railway locomotive Traction Motors Non-magnetic Forging Forged Retaining Rings factory

AMS 5726,AMS 5731,AMS 5732,AMS 5734,AMS 5737,AMS 5853,AMS 5895 forged forging Electromagnetic Stirring Rolls Rollers for continuous casting machine

AMS 5726,AMS 5731,AMS 5732,AMS 5734,AMS 5737,AMS 5853,AMS 5895 Forged Forging Valve Balls,valve Bonnets,valve Body Bodies ,valve Stems,valve closures, valve seat rings, valve core, valve discs,for H type two way 2‐way one way back pressure valves, ball valve,check valve,gate valve

AMS 5726,AMS 5731,AMS 5732,AMS 5734,AMS 5737,AMS 5853,AMS 5895 Forged Forging Steel nuclear Power reactor coolant pumps Rotor Impellers

AMS 5726,AMS 5731,AMS 5732,AMS 5734,AMS 5737,AMS 5853,AMS 5895 Forged Forging venturi cone meter Body Bodies Blocks

AMS 5726,AMS 5731,AMS 5732,AMS 5734,AMS 5737,AMS 5853,AMS 5895Forged Forging Steel gate valves Body Bodies bespoke flat bars

AMS 5726,AMS 5731,AMS 5732,AMS 5734,AMS 5737,AMS 5853,AMS 5895 forging steel Oil measurement valve Spool Ultrasonic flow meter bodies Body

AMS 5726,AMS 5731,AMS 5732,AMS 5734,AMS 5737,AMS 5853,AMS 5895 Forged Forging Steel double studded adapter flange

AMS 5726,AMS 5731,AMS 5732,AMS 5734,AMS 5737,AMS 5853,AMS 5895 Forged Forgig Steel nuclear reactor coolant pump Casing Shells body bodis blocks,nuclear reactor coolant pumps containment seal chamber Rooms,nuclear reactor coolant pumps containment seal chamber Rooms

AMS 5726,AMS 5731,AMS 5732,AMS 5734,AMS 5737,AMS 5853,AMS 5895 Forged Forging turbomachinery turbo centrifugal compressor Impeller,Compressor Shrouded Impellers

AMS 5726,AMS 5731,AMS 5732,AMS 5734,AMS 5737,AMS 5853,AMS 5895 Forged Forging Steel PUMP Casing cover.PUMP BARREL,pump impeller,pump shafts, pump housing, pump shells,pump body,pump wear rings,pump case casing.

AMS 5726,AMS 5731,AMS 5732,AMS 5734,AMS 5737,AMS 5853,AMS 5895 Forged Forging forge Steel transition Cone

AMS 5726,AMS 5731,AMS 5732,AMS 5734,AMS 5737,AMS 5853,AMS 5895Forged Forging Steel Pressure Vessel Reactor Nozzles

AMS 5726,AMS 5731,AMS 5732,AMS 5734,AMS 5737,AMS 5853,AMS 5895 Forged Forging Gas Compressor Turbine Blades steel Flat Rectangles Bars

AMS 5726,AMS 5731,AMS 5732,AMS 5734,AMS 5737,AMS 5853,AMS 5895 Forged Forging Gas steam turbine disks, turbine impeller,turbine blisk,turbine discs,turbine wheel discs

AMS 5726,AMS 5731,AMS 5732,AMS 5734,AMS 5737,AMS 5853,AMS 5895 Forging Steel Forging Forged Gas Steam Turbine Doubled-headed Double end Studs Fasteners Bolts bolting

AMS 5726,AMS 5731,AMS 5732,AMS 5734,AMS 5737,AMS 5853,AMS 5895 Forging Steel gas steam Turbine Guide Rings,Turbine shroud rings,seal rings Labyrinth Rings Packing Seal Diaphragm & Seal Ring Rotor End Rings contours Casing Rings

AMS 5726,AMS 5731,AMS 5732,AMS 5734,AMS 5737,AMS 5853,AMS 5895 Forged Forging Steel Gas Steam turbine diaphragm diapharagm nozzles

AMS 5726,AMS 5731,AMS 5732,AMS 5734,AMS 5737,AMS 5853,AMS 5895 Forged Forging Gas Turbine LPT 1st & 2st 2nd Stg Stage Turbine Case Casings

AMS 5726,AMS 5731,AMS 5732,AMS 5734,AMS 5737,AMS 5853,AMS 5895 Forged Forging Steel power plant steam turbine control reheat valve disc Disk

AMS 5726,AMS 5731,AMS 5732,AMS 5734,AMS 5737,AMS 5853,AMS 5895Forged forging Gas Steam Turbine Valve Spindles/Stems/Rods,

AMS 5726,AMS 5731,AMS 5732,AMS 5734,AMS 5737,AMS 5853,AMS 5895 Forging Steel Gas Steam Turbine MSV/GV/CV/CRV Valve Seats, Valve Cores, Valve Sleeves Spools,,Main Steam Valve Covers Bonnets Sleeves

AMS 5726,AMS 5731,AMS 5732,AMS 5734,AMS 5737,AMS 5853,AMS 5895 forged forging steel pipes tubes shells piping tubing barrels housing, tube sheets,baffle plates, nozzles, channel flanges for boiler, heat exchanger,pressure vessel,reactors, heaters

AMS 5726,AMS 5731,AMS 5732,AMS 5734,AMS 5737,AMS 5853,AMS 5895Forged Forging Nickel Alloy Bore Protector

AMS 5726,AMS 5731,AMS 5732,AMS 5734,AMS 5737,AMS 5853,AMS 5895 is normally used in aviation and power engineering for heavy-duty rotors,gas turbine blades, steam turbines, pressure equipment parts and reactors,jet engines and rockets, exhaust systems. Also used in cryogenics and cryotechnics.

AMS 5726,AMS 5731,AMS 5732,AMS 5734,AMS 5737,AMS 5853,AMS 5895is rolled or forged from temperature of 1900/2050 °F(1038/1121 °C) using a short soaking period. It is slightly more resistance to deformation than the austentitic stainless steels during hot working. Do not forge below 1700 °F(927 °C).

AMS 5726,AMS 5731,AMS 5732,AMS 5734,AMS 5737,AMS 5853,AMS 5895 forged parts production shall be performed by using one of the following methods:

Electric arc welding process (remelting if necessary)

Induction furnace process vacuum melting (or remelting, if necessary – e.g. ESR

Argon-Oxygen Decarburization (AOD) method.

FOllowing is chemical compostion of AMS 5726,AMS 5731,AMS 5732,AMS 5734,AMS 5737,AMS 5853,AMS 5895 forged parts

Iron (Fe) 49.2 to 59

Nickel (Ni) 24 to 27

Chromium (Cr) 13 to 16

Titanium (Ti) 1.9 to 2.3

Manganese (Mn) 1.0 to 2.0

Molybdenum (Mo) 1.0 to 1.5

Silicon (Si) 0 to 1.0

Vanadium (V) 0.1 to 0.5

Aluminum (Al) 0 to 0.35

Carbon (C) 0 to 0.080

Phosphorus (P) 0 to 0.025

Sulfur (S) 0 to 0.015

Boron (B) 0.0010 to 0.010

Following of AMS 5726,AMS 5731,AMS 5732,AMS 5734,AMS 5737,AMS 5853,AMS 5895 forging parts heat treatment nechanical property Delivery condition :

Ultimate Tensile Strength:

125 KSI min (862 MPA min): Gauge: .001 - .0015

130 KSI min (896 MPA min): Gauge .0015 - .002

135 KSI min (931 MPA min): Gauge .002 - .004

140 KSI min (965 MPA min): Gauge> .004

Elongation:

4% min: Gauge: .001 - .0015

8% min: Gauge .0015 - .002

10% min: Gauge .002 - .004

15% min: Gauge > .004

All our AMS 5726,AMS 5731,AMS 5732,AMS 5734,AMS 5737,AMS 5853,AMS 5895 forging parts will have following testing procedure

Visual inspections – Direct and Indirect

Magnetic particle

Dye penetrant – Visible and Fluorescent

Ultra-sonic testing

Radiograph

Metallurgical Testing

Macro & micro

Grain size determination

Charpy Impact testing

V notch Charpy

Hardness testing including micro and

macro Vickers tests

Tensile testing

Microscope imaging

Marking of finished AMS 5726,AMS 5731,AMS 5732,AMS 5734,AMS 5737,AMS 5853,AMS 5895 forged parts

Unless otherwise indicated in the drawing or in the part specification, marking with serial number shall be carried out by mean of stamping according to clients technical manual following provisions indicated on the part dr awing.

The following marking shall be applied before removing any material from the forging:

• name or trademark of manufacturer of the forging;

• serial number of the forging of origin

• position from which the piece is removed with reference to the part specification.

Welcome your inquiry of AMS 5726,AMS 5731,AMS 5732,AMS 5734,AMS 5737,AMS 5853,AMS 5895 forging forged steel parts