Description

Jiangsu Liangyi professional manufacturer of AISI 410Cb, AISI 410 CB, AISI XM-30,XM30 UNS S41040 open die forging parts and seamless rolled steel forged rings,410CB forged forging steel gas steam turbine blade bolts from china

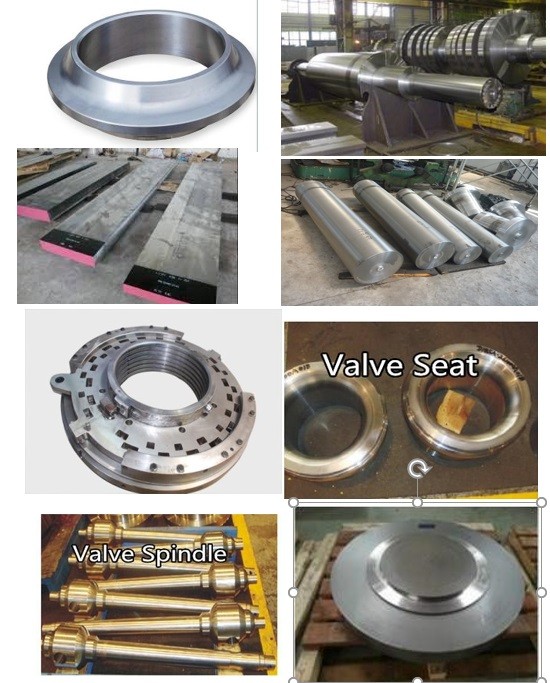

Following is the shape of AISI 410Cb, AISI 410 CB, AISI XM-30,XM30 UNS S41040 forging steel material that we could do is:410CB Forged Steel round bars square bars Flat bars Rectangles Bars Rods,XM-30 Forged forging steel rings seamless rolled rings,XM30 Forged Forging Steel Hubs housing shell Sleeves Bushes Bushing Cases Hollow Bars,UNS S41040 Forged Forging Steel Discs Disks Blocks plates,AISI 410 CB Forged Forging Steel Pipe Tubes Tubings Piping Shells Casings Case barrels Housings.

Following is forging products of AISI 410Cb, AISI 410 CB, AISI XM-30,XM30 UNS S41040 that is used in following industry

AISI 410Cb Forged Forging Gas Compressor Turbine Blades steel Flat Rectangles Bars

AISI 410 CB Forged Forging Gas steam turbine disks, turbine impeller,turbine blisk,turbine discs

XM-30 Forging Steel Forging Forged Gas Steam Turbine Doubled-headed Double end Studs Fasteners Bolts

XM30 Forged Forging Steel gas steam Turbine Guide Rings,seal rings Labyrinth Rings Packing Seal Diaphragm & Seal Ring Rotor End Rings contours Casing Rings

410CB is an AOD + ESR melted martensitic stainless steel alloy. This alloy has elevated strength and toughness as compared to standard 410. The addition of columbium allows for improved grain size control and greater ease in heat treating. This grade is used primarily in the power generation market.

The production standard of AISI 410CB forged steel blade steel is as following:GE B50A947, ASTM A276 , A479, GE B50A790, DOD-F-24669, DRESSER RAND CM-8782, GE B50A947B

FOllowing is chemical compostion of AISI 410CB forged steel flat bars

Iron (Fe) 84.5 to 89

Chromium (Cr) 11 to 13

Manganese (Mn) 0 to 1.0

Silicon (Si) 0 to 1.0

Niobium (Nb) 0.050 to 0.3

Carbon (C) 0 to 0.18

Phosphorus (P) 0 to 0.040

Sulfur (S) 0 to 0.030

FOllowing is mechanical property for 21CrMoV5-11 forging steel pipes

Mechanical properties in the quenched and tempered condition - at +20C

Yield strength :Min 860 MPA Test according to standard of EN 10002-1

Tensile stress:690 MPA Test according to standard of EN 10002-1

Elongation Min 13% Test according to standard of EN 10002-1

Cross section reduction:Min 45% Test according to standard of EN 10002-1

We should do following following NON-DESTRUCTIVE TEST for all AISI 410CB steam turbine blade flat bars

Verification inspection of all AISI 410 CB forged steel bars.

100% Ultrasonic inspection of all bars above 40mm size according to EN 10308 type 1a and 1c table 1). Acceptance criteria are as follows.

· d or (a,b) = 200mm quality class 4

· d or (a,b) = 200mm quality class 3

In general, the decision limit for loss of back wall echo is 3 dB and for the real reflector length max. 10mm.

The finished AISI 410 CB forged round bars shall be straight, sound and free from internal and surface defects viz., cracks,piping, scabs, laps, hairline cracks, etc. The bars shall be free from twists and bends.

, The surface of the bars shall be smooth without any laps, rolled in scales, etc. Dents roll marks and scratches are permitted provided their depth does not exceed half the tolerance limits specified