Description

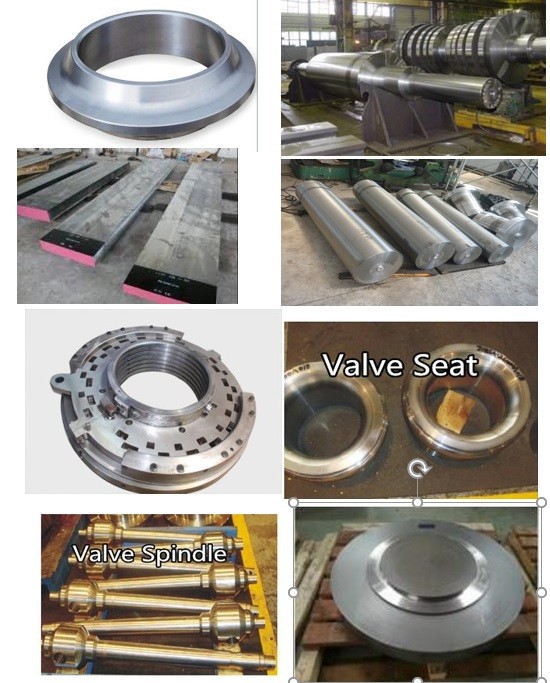

Jiangsu Liangyi is professional manufacturer of 38KHN3MFА,38ХН3МФА open die forging parts and forged steel gas steam turbine generator rotor shafts ,,turbo generator,Turbomachines,Turbomachinery,turbogenerator forging steel shafts factory from china

38KHN3MFА,38ХН3МФА is is used: for the production of rings of turbogenerators and most critical highly loaded parts operating at temperatures up to +400 °C;

Following is the shape of 38KHN3MFА,38ХН3МФА forging steel material that we could do is:38KHN3MFА Forged Steel round bars square bars Flat bars Rectangles Bars Rods,30 CrMoNiV 5 11 Forged forging steel rings seamless rolled rings, 38ХН3МФА Forged Forging Steel Hubs housing shell Sleeves Bushes Bushing Cases Hollow Bars,38KHN3MFА Forged Forging Steel Discs Disks Blocks plates, 38ХН3МФА Forged Forging Steel Pipe Tubes Tubings Piping Shells Casings Case barrels Housings.38KHN3MFА Forged Forging Steel Gas Steam Turbine Rotors Shafts,38ХН3МФА Forged Forging Gas Compressor Turbine Blades turbine Vane steel Flat Rectangles Bars,38KHN3MFА Forged Forging Steel gas steam Turbine Guide Rings,seal rings Labyrinth Rings Packing Seal Diaphragm & Seal Ring Rotor End Rings contours Casing Rings,,38ХН3МФА Forged forging Gas Steam Turbine Valve Spindles/Stems/Rods,38KHN3MFА Forging Forged Gas Steam Turbine Doubled-headed Double end Studs Fasteners Bolts

Following is production standard of 38KHN3MFА, 38ХН3МФА forged parts

ГОСТ 8479-70;

ГОСТ 2879-2006; ГОСТ 1133-71; ГОСТ 2590-2006; ГОСТ 2591-2006;

ГОСТ 103-2006;

ГОСТ 14955-77; ГОСТ 4543-71; ГОСТ 7417-75; ГОСТ 1051-73; ГОСТ 8559-75; ГОСТ 8560-78;

The chemical compostion of 38KHN3MFА,38ХН3МФА forging steel steam turbine rotor shafts material is as followsing

C 0.33 - 0.4

Si 0.17 - 0.37

Mn 0.25 - 0.5

Ni 3 - 3.5

S 0.025 max

P 0.025 max

Cr 1.2 - 1.5

Mo 0.35 - 0.45

V 0.1 - 0.18

Cu 0.3 max

The mechanical property of 38KHN3MFА forged steel steam turbine rotor material is as followings

MECHANICAL PROPERTIES Of 26NiCrMo8-5 forged turbine blade steel is as follows

MIN. YIELD strength:Min 1080MPA

TENSIL STRENGT:1180 MPa

ELONGATION Min 12 %

Reduction Min 50%

All our 38ХН3МФА forged turbine material will be in following test

Tangential Tensile Strength Test for every pieces of 38ХН3МФА forged turbine rotor shafts

Tangential Notched bar Impact Test for every pieces of 38ХН3МФА forged turbine blade steel

Axial Core Tensile Strength Test for every pieces of 38ХН3МФА forged turbine generator rotor shafts

Axial Core Notched bar Impact Test for every pieces of 30 CrMoNiV 5 11 forged gas steam turbine rotor shafts

Radial Core Tensile Strength Test for every pieces of 38ХН3МФА forged turbine rotor shafts

Radial Core Notched bar Impact Test for every pieces of 38ХН3МФА forged turbine rotor shafts

UT Examination for every pieces of 38ХН3МФА forged turbine Gas Steam Turbine Valve Spindles/Stems/Rods

Boroscope Examination and MT Test for every pieces of 38ХН3МФА forged turbine rotor shafts

Visual and Dimensional for every pieces of 38ХН3МФА forged turbine rotor shafts

Measurement of Magnetic Induction for every pieces of 38ХН3МФА forged turbine rotor shafts

Marking for every pieces of 38KHN3MFА forged turbine Gas Steam Turbine Doubled-headed Double end Studs Fasteners Bolts

Measurement of Residual Stress for every pieces of 38KHN3MFА forged turbine rotor shafts

Checking for Completeness of QA-Documents for every pieces of 38ХН3МФА forged turbine rotor shafts

All our Reports 38KHN3MFА,38ХН3МФА forging material shall be provided of all activities as indicated on the Inspection and Test Plan

These shall include:

1) Purchase order number and order item of 38KHN3MFА material

2) Drawing number. of 38ХН3МФА forging parts

3) Clients definition specification number (ATD).38ХН3МФА forging

4) Number of forgings in the batch. in 38ХН3МФА forging steel flat bars

5) Batch identity of the 38KHN3MFА forgings.

6) Statement of conformity with the Manufacturing, Inspection and Control Process Plan[MPP] and any agreed deviations.of 38KHN3MFА forging steel material

7) Statement of compliance with the forging deformation requirements. for 38KHN3MFА material

8) Details of heat treatments including time at soaking temperature, cooling methods and terminal temperature on cooling (where required by the material specification). of 38ХН3МФА forging pipes

9) Chemical analysis of all 38ХН3МФА forging parts

10) Results of required mechanical tests. of 38ХН3МФА forging rings

11) Results of hardness tests of all 38KHN3MFАforgings

12) Results of required microstructural tests (where applicable) of 38KHN3MFА forging steel

13) Certificate of conformity of dimensions for 38KHN3MFА forged parts

Welcome your inquiry of 38KHN3MFА,38ХН3МФА forging forged steel parts