Description

Jiangsu Liangyi professional manufacturer of 1.6981, 21CrMoNiV4-7,21 CrMoNiV 4-7,21CrMoNiV4.7 open die forging parts and forged steel gas steam turbine generator rotor shafts factory from china

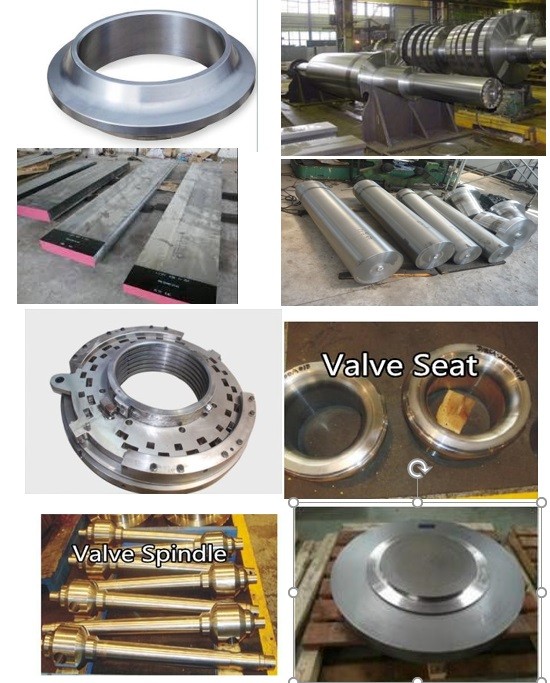

Following is the shape of 1.6981, 21CrMoNiV4-7,21 CrMoNiV 4-7,21CrMoNiV4.7 Forging steel material that we could do is:21CrMoNiV4-7 Forged Steel round bars square bars Flat bars Rectangles Bars Rods, 21CrMoNiV4.7 Forged forging steel rings seamless rolled rings, 21CrMoNiV4.7 Forged Forging Steel Hubs housing shell Sleeves Bushes Bushing Cases Hollow Bars,21 CrMoNiV 4-7 Forged Forging Steel Discs Disks Blocks plates, 1.6981 Forged Forging Steel Pipe Tubes Tubings Piping Shells Casings Case barrels Housings.21CrMoNiV4.7 Forged Forging Steel Gas Steam Turbine Rotors Shafts,21CrMoNiV4-7 Forged Forging Gas Compressor Turbine Blades turbine Vane steel Flat Rectangles Bars,21CrMoNiV4.7 Forged Forging Steel gas steam Turbine Guide Rings,seal rings Labyrinth Rings Packing Seal Diaphragm & Seal Ring Rotor End Rings contours Casing Rings,,21CrMoNiV4.7 Forged forging Gas Steam Turbine Valve Spindles/Stems/Rods,1.6981 Forging Forged Gas Steam Turbine Doubled-headed Double end Studs Fasteners Bolts

CHEMICAL COMPOSITION (WEIGHT %) of 21CrMoNiV4-7 forged steam turbine components as followings

Carbon (C) 0.17~0.25

Silicon (Si) 0.15~0.35

Manganese (Mn) 0.35~0.85

Phosphorus (P) 0.030 max

Sulfur (S) 0.035 max

Chromium (Cr) 0.90~1.20

Molybdenum (Mo) 0.65~0.80

Nickel (Ni) 0.20~0.80

Vanadium (V) 0.25~0.35

FOllowing is HEAT TREATMENT way of 21CrMoNiV4.7 forging steel parts

Hardening: 900 - 950°C / air, oil, polymer * or water dipping, With center cooling rate comparable to oil quenching,Tempering: 680 - 720 °C (Min. 2 hours),The duration of tempering as well as the controlled cooling rate are to be chosen to achieve minimum residual stress

Following is mechanical property properties of 21CrMoNiV4-7 forging gas turbine parts in room temperature:

0.2% Proof Stress(N/mm^)550 - 700

Tensile Strength(N/mm')>700

Elongation(%)> 15

Red. in area(%)>40

Impact Joule >24

Hardness>215HB

FOllowing is Tensile tests at elevated temperature at 560°C. In accordance with EN 10002-5 a for 21CrMoNiV4.7 forged steel discs

0.2% Proof Stress > 290 Mpa, Tensile Strength >400MPa, Elongation > 18 % Reduction in area > 68

All our finish production of 1.6981 forged steel material should will done in Following NDE shall be performed in delivery condition:

- Visual inspection

Material verification test

- 100% UT- inspection according to EN 10228-3 (table 3). Depending on the forging geometry,

following inspection types are applicable:

- for 21CrMoNiV4-7 forging bar shape components; type 1 (inspection may also be carried out as per EN10308 for type 1)

- for 21CrMoNiV47 forged discs and plate- like components: type 2

- for 21CrMoNiV4-7 forging ring or bushing- like components: type 3b and 3

Welcome your inquiry of 1.6981, 21CrMoNiV4-7,21 CrMoNiV 4-7,21CrMoNiV4.7 forging forged steel parts