Description

Jiangsu Liangyi professional manufacturer of 1.6985,28CrMoNiV4-9,28CrMoNiV4.9,28 CrMoNiV 4 9,28CrMoNiV49 open die forging forged parts and forged steam gas turbine generator rotor shafts,,turbo generator,Turbomachines,Turbomachinery,turbogenerator forging steel shafts , and 28CrMoNiV4-9 Gas steam turbine high pressure and intermediate pressure rotors, monobloc rotors, shaft ends, hollow shafts factory from china

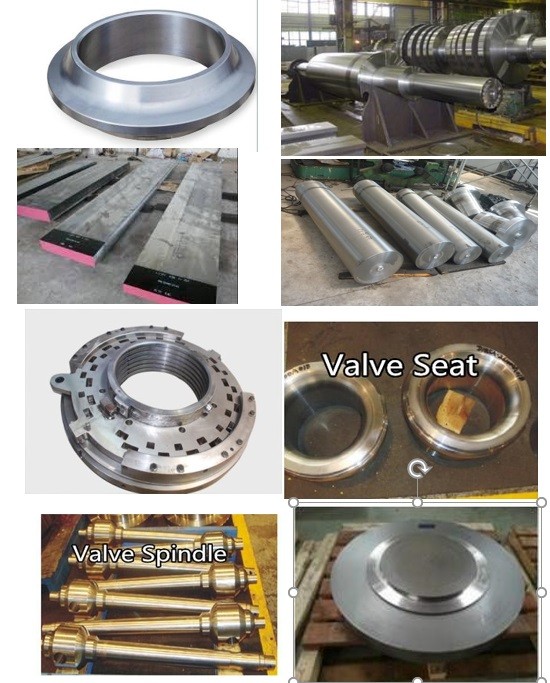

Following is the shape of 1.6985,28CrMoNiV4-9,28CrMoNiV4.9,28 CrMoNiV 4 9,28CrMoNiV49 forging steel material that we could do is:1.6985,28CrMoNiV4-9,28CrMoNiV4.9,28 CrMoNiV 4 9,28CrMoNiV49 Forged Steel round bars square bars Flat bars Rectangles Bars Rods,28CrMoNiV4.9 Forged forging steel rings seamless rolled rings,28CrMoNiV49 Forged Forging Steel Hubs housing shell Sleeves Bushes Bushing Cases Hollow Bars,28CrMoNiV4-9 Forged Forging Steel Discs Disks Blocks plates,28 CrMoNiV 4 9 Forged Forging Steel Pipe Tubes Tubings Piping Shells Casings Case barrels Housings.

1.6985,28CrMoNiV4-9,28CrMoNiV4.9,28 CrMoNiV 4 9,28CrMoNiV49 Forged Forging Steel Gas Steam Turbine Rotors Shafts

1.6985,28CrMoNiV4-9,28CrMoNiV4.9,28 CrMoNiV 4 9,28CrMoNiV49 Forged Forging Gas Compressor Turbine Blades steel Flat Rectangles Bars

1.6985 Forged Forging Steel Gas Steam turbine diaphragm diapharagm nozzles

28CrMoNiV49 Forged Forging Steel gas steam Turbine Guide Rings,seal rings Labyrinth Rings Packing Seal Diaphragm & Seal Ring Rotor End Rings contours Casing Rings/Blade Fitting Rings

,28 CrMoNiV 4 9 Forging Forged Steel Gas Turbine Wheels Discs

28CrMoNiV4-9 Forged Forging Gas Turbine LPT 1st & 2st 2nd Stg Stage Turbine Case Casings

28 CrMoNiV 4 9 Forged Forging Rolled Steel Gas Turbine LPT 1st & 2st 2nd Stg Stage Steam Turbine shrouds turbines journal and thrust bearing

28CrMoNiV49 Forged Forging Steel power plant steam turbine control reheat valve disc Disk

1.6985 Forged forging Gas Steam Turbine Valve Spindles/Stems/Rods,

28 CrMoNiV 4 9 Forging Forged Gas Steam Turbine Doubled-headed Double end Studs Fasteners Bolts

1.6985 Forging Steel Gas Steam Turbine MSV/GV/CV/CRV Valve Seats, Valve Cores, Valve Sleeves Spools,,Main Steam Valve Covers Bonnets Sleeves

28CrMoNiV49 Forged Forging Steel Gas Steam Turbine Oil Guards nozzle Bearing Gland Seal Sealing Rings,

28CrMoNiV4-9 forging Steam Gas Turbine Inlet Guide Vane IGV Control Ring Lower Upper Half,Outer Inner Transition Ducts,

28CrMoNiV4.9 forged Forged Forging Rolled Gas Steam Turbine Inner Outer Heat Shields,

The maximum diamter of 1.6985,28CrMoNiV4-9,28CrMoNiV4.9,28 CrMoNiV 4 9,28CrMoNiV49 forged turbine rotor shafts is 2.5 meter, the maximum weight of 28CrMoNiV4-9 forged gas steam turbine rotor shafts that we could produce is 30 tons, the maximum length of 28CrMoNiV4.9 forging turbine rotor shafts that we could do is 12 meter

The Melting methods for 1.6985,28CrMoNiV4-9,28CrMoNiV4.9,28 CrMoNiV 4 9,28CrMoNiV49 forging steel material is Ef / Eaf + Lf + Vd / ESR that depends on clients needs,The remelted variant (ESR) for 1.6985,28CrMoNiV4-9guarantees the highest purity and homogeneity.

For all 28CrMoNiV4-9 forged turbine rotor shafts raw material should be in Inspection of non-metallic inclusions, inaccordance with the standard ASTM E45-A method, requiring A, B, C, D ≤ 1.5

28CrMoNiV4-9 forging steel materioal belongs to the class of 1%Cr steels which have been used for steam turbine components in fossil power plants (plants operating at >22 MPa at 538–565 °C) since the 1960s. In addition to exhibiting decreasing mechanical strength with increasing temperature, the material provides insufficient corrosion resistance at temperatures higher than 550 °C because of the relatively low chromium content.

1.6985 forging chemnical compostion

Carbon (C%):Min: 0,25 Max: 0,30

Manganese (Mn%) :Min: 0,30 Max: 0,80

Silicon (Si%) :≤ 0,15

Phosphorus (P%) :≤0,01

Sulfur (S%):≤0,007

Chrome (Cr%):1,00 Max: 1,30

Nickel (Ni%):Min: 0,50 Max: 0,75

Molybdenum (Mo%):Min: 0,75 Max: 1,00

Aluminum (Al%) :≤ 0,010

Vanadium (V%):Min: 0,25 Max: 0,35

Mechanical properties of 28CrMoNiV4-9 forging gas turbine rotor shafts is as follows and Taking specimen according to the ISO 6892-1 standard for tensile test,Taking specimen according to the ISO 148-1 for impact test

tensiel strength Rm:700-850Mpa

yield strength Rp0.2≥550Mpa

Elongation in 50mm min ≥15%(Longitud)

Elongation in 50mm min ≥15%(Transv)

Reduction of area ≥40%(Longitud)

Reduction of area ≥40%(Transv)

AKv≥24J(+20℃ Longitud)

AKv≥16J(+20℃Transv)

Welcome your inquiry of 1.6985,28CrMoNiV4-9,28CrMoNiV4.9,28 CrMoNiV 4 9,28CrMoNiV49 forging forged steel parts