Description

Jiangsu Liangyi is professional manufacturer of Inconel 706,UNS N09706,,Alloy 706,Inconel ALloy 706 open die forging parts and seamless rolled steel forged rings from china

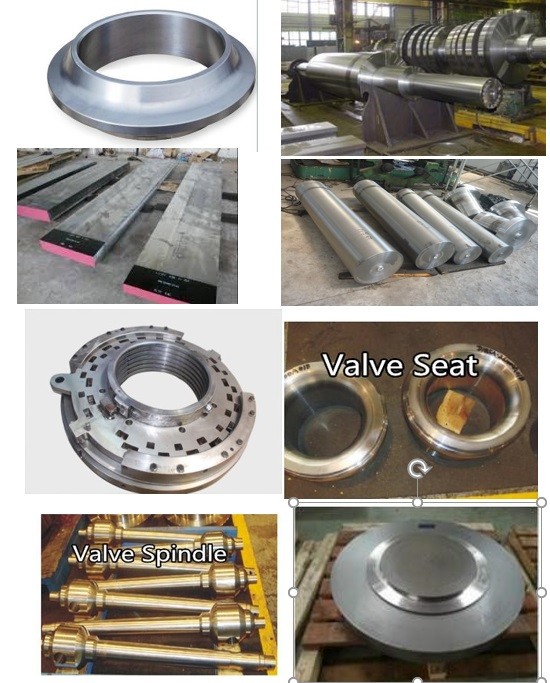

Following is the shape of Inconel 706,Inconel ALloy 706, Alloy 706,UNS N09706 forging steel material that we could do is:Inconel 706 Forged Steel round bars square bars Flat bars Rectangles Bars Rods,Inconel ALloy 706 Forged forging steel rings seamless rolled rings,Alloy 706 Forged Forging Steel Hubs housing shell Sleeves Bushes Bushing Cases Hollow Bars,UNS N09706 Forged Forging Steel Discs Disks Blocks plates,Inconel 706 Forged Forging Steel Pipe Tubes Tubings Piping Shells Casings Case barrels Housings.

Following is forging products of Inconel 706,Inconel ALloy 706, Alloy 706,UNS N09706 material that is used in following industry

Alloy 706 Forged Forging Turbine and Compressor Labyrinth Shaft Seals

Inconel Alloy 706 Forged Forging turbomachinery turbo centrifugal compressor Impeller,Compressor Shrouded Impellers

Alloy 706 Forged Forging Gas Compressor Turbine Blades steel Flat Rectangles Bars

Alloy 706 Forged Forging Gas Compressor Turbine shafts

Alloy 706 Forged Forging Gas steam turbine disks, turbine impeller,turbine blisk,turbine discs,turbine wheel discs,compressor discs

Inconel Alloy 706 Forging Steel Forging Forged Gas Steam Turbine Doubled-headed Double end Studs Fasteners Bolts bolting

Inconel Alloy 706 Forging Steel gas steam Turbine Guide Rings,Turbine shroud rings,seal rings Labyrinth Rings Packing Seal Diaphragm & Seal Ring Rotor End Rings contours Casing Rings

Inconel Alloy 706 Forged Forging Steel Gas Steam turbine diaphragm diapharagm nozzles

Inconel 706 Forged Forging Gas Turbine LPT 1st & 2st 2nd Stg Stage Turbine Case Casings,diffuser cases.

Inconel 706 Forged Forging Steel power plant steam turbine control reheat valve disc Disk

UNS N09706 Forged forging Gas Steam Turbine Valve Spindles/Stems/Rods,

Inconel 706 Forging Steel Gas Steam Turbine MSV/GV/CV/CRV Valve Seats, Valve Cores, Valve Sleeves Spools,,Main Steam Valve Covers Bonnets Sleeves

Inconel 706 is is a nickel-iron-chromium. As alloy 706 is a precipitation-hardenable alloy that provides high mechanical strength in combination with good fabricability

FOllowing is chemical compostion and mechanical property of Inconel ALloy 706 forged steel rings

· No stringers in excess of 1 mm (0.039”) length in all other areas

|

Material |

Chemical Composition (%) |

Heat Treatment |

Mechanical Properties |

|||||||||||||||||||

|

Ni |

Cr |

Nb |

Ti |

Al |

C |

Cu |

Mn |

S |

P |

B |

Co |

Fe |

Tensile Strength min |

Yield Strength A min (0.2% offset method) |

Elongation, min % |

Reduction of area, min % |

Charpy V-notch impact, room temperature, min |

|||||

|

Mpa |

Ksi |

Mpa |

Ksi |

(%) |

(%) |

ft-lb |

J |

|||||||||||||||

|

INCONEL 706 |

39 - 44 |

14.5 - 17.5 |

2.5 - 3.3 |

1.5 - 2.0 |

4.0 max. |

0.06 max. |

0.30 max. |

0.35 max. |

0.005 max. |

0.010 max. |

0.006 max. |

1.00 max. |

Bal. |

A |

1245 |

180.5 |

979 |

142 |

17 |

19 |

23 |

31 |

Following of Inconel 706 forging parts heat treatment way of inconel 706 forged turbine discs

One Heat Treatment way is as following

Solution Treatment - 1700-1850°F (925-1010°C) for a time commensurate with section size, air cool.

Stabilizing Treatment - 1550°F (845°C)/3 hr, air cool.Precipitation Treatment - 1325°F (720°C)/8 hr, furnace cool at 100°F (55°C)/hr to 1150°F (620°C)/8 hr, air cool.

Another Heat Treatment way is as following

Solution Treatment - 1700-1850°F (925-1010°C) for a time commensurate with section size, air cool. Precipitation Treatment - 1350°F (730°C)/8 hr, furnace

cool at 100°F (55°C)/hr to 1150°F (620°C)/8 hr, air cool.

All our finished inconel 706 forged turbine discs will have creep and rupture data, including rupture-strength curve

All our finished inconel 706 forged parts will have NDT UT & MT result within the mill cert. NDT shall follow below criteria:

NDT Ultrasonic:

· The forging shall not have any UT indication greater than 0.039” (1 mm)

· All detected indications must be separated at least 2” (51 mm) in all directions.

NDT Magnetic Particle

· No linear indications.

· No stringers in excess of 1 mm (0.039”) length in all coupling fits and bearing journals.

· No stringers in disk bores or blade root areas.

· No stringers in excess of 1 mm (0.039”) length in all other areas

An inspection certificate 3.1 according EN 10204 of our inconel 706 forged bars should have following

purchase order, item, serial n°, drawing number and number of the technical purchasing

specification

material designation

heat n° and heat analysis

method of melting

manufacturing procedure

heat treatment: cooling method (rates and mean of cooling) and measured temperatures.

All heat treatment conditions have to be quoted in a graphic temperature against time

sequence (including all re-heat-treatments). Reports including only average holding

temperatures and times are acceptable.

results of metallographic analysis

mechanical tests certificates, including single values

results and recording of NDT. A dedicated certificate for each performed NDT is required

dimensional report (tabular or graphically) complete of a certificate of compliance

Welcome your inquiry of Inconel 706,Inconel ALloy 706, Alloy 706,UNS N09706) forging forged steel parts