Description

Jiangsu Liangyi is professional manufacturer of ASTM A182 Grade F55,A182-F55 ,F55 ,ASTM A 182 F 55 open die forging parts and seamless rolled steel forged rings from china

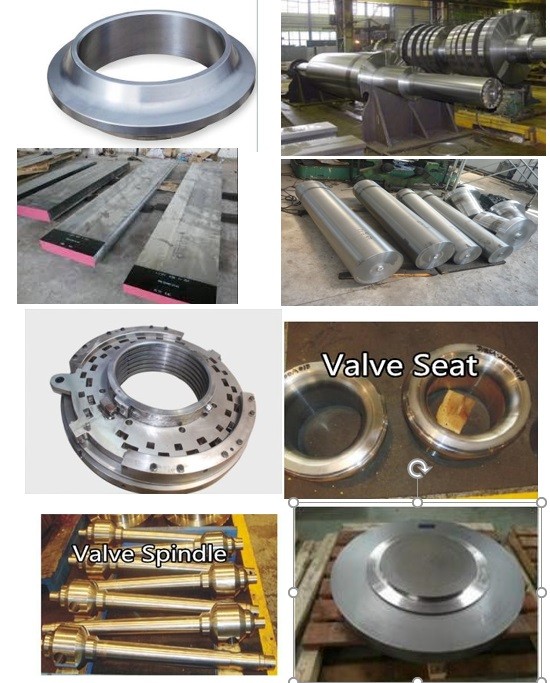

Following is the shape of ASTM A182 Grade F55,A182-F55 ,F55 ,ASTM A 182 F 55 forging steel material that we could do is:A182-F55 Forged Steel round bars square bars Flat bars Rectangles Bars Rods,ASTM A 182 F 55 Forged forging steel rings seamless rolled rings,ASTM A182 Grade F55 Forged Forging Steel Hubs housing shell Sleeves Bushes Bushing Cases Hollow Bars,ASTM A182 Grade F55 Forged Forging Steel Discs Disks Blocks plates,A182-F55 Forged Forging Steel Pipe Tubes Tubings Piping Shells Casings Case barrels Housings.

Following is forging products of ASTM A182 Grade F55,A182-F55 ,F55 ,ASTM A 182 F 55 material that is used in following industry

ASTM A 182 F 55 forging Forged Drilling Pipes Tubes Drill Rods drill Drilling collar

ASTM A182 Grade F55 Forged Forging Turbine and Compressor Labyrinth Shaft Seals

ASTM A 182 F 55 Forged/Forging Blow Out Blowout Preventer RAM Annular dual Bop Body Bodies Block

ASTM A182 Grade F55 Forged Forging drilling tools,risers,connectors,flexible joint ,seals,flanges gasket

A182-F55 Forged Forging Valve Balls,valve Bonnets,valve Body Bodies ,valve Stems,valve closures, valve seat rings, valve core, valve discs,for H type two way 2‐way one way back pressure valves, ball valve,check valve,gate valve

ASTM A182 Grade F55 Forged Forging Steel nuclear Power

ASTM A 182 F 55 Forged Forging Steel Butterfly Valve Main Shafts Spindles

ASTM A182 Grade F55 Forged Forging Swept branches outlets steel fittings swept saddles

A182-F55 Forged Forging downhole drilling tool Mud Motor Splined Drive shafts,Down hole Electric electrical submersible pumps ESP motor Splined Shaft

ASTM A 182 F 55 Forged Forging Steels Christmas Trees wellhead Spool Body Bodies cylinder

ASTM A182 Grade F55 Forged Forging venturi cone meter Body Bodies Blocks

ASTM A182 Grade F55 Forged Forging Steel gate valves Body Bodies bespoke flat bars

A182-F55 forged steel Flowseal cryogenic High Performance BV Butterfly Valves HPBV shaft

A182-F55 forging steel Oil measurement valve Spool Ultrasonic flow meter bodies Body

ASTM A 182 F 55 Forged Forging Steel double studded adapter flange

ASTM A 182 F 55 Forged Forging Steel integral Mud Flange Flanged outlet Studded crosses

ASTM A182 Grade F55 Forged Forging Steel Casing Heads,Tubing Heads,Casing Hangers,Tubing Hangers,Tubing Spools,Casing Spools,Spacer Spools

ASTM A 182 F 55 Forged Forgig Steel nuclear reactor coolant pump Casing Shells body bodis blocks,nuclear reactor coolant pumps containment seal chamber Rooms,nuclear reactor coolant pumps containment seal chamber Rooms

ASTM A 182 F 55 Forged Forging turbomachinery turbo centrifugal compressor Impeller,Compressor Shrouded Impellers

ASTM A 182 F 55 Forged Forging Steel Forged Single Double Bossed boss Blanks FLANGED BOSSES

ASTM A 182 F 55 Forged Forging Steel PUMP Casing cover.PUMP BARREL,pump impeller,pump shafts, pump housing, pump shells,pump body,pump wear rings,pump case casing.

ASTM A182 Grade F55 Forged Forging forge Steel transition Cone

ASTM A182 Grade F55 Forged Forging Steel Pressure Vessel Reactor Nozzles

A182-F55 forged forging steel pipes tubes shells piping tubing barrels housing, tube sheets,baffle plates, nozzles, channel flanges for boiler, heat exchanger,pressure vessel,reactors, heaters

A182-F55 is described as a super duplex stainless steel with a microstructure of 50:50 austenite and ferrite. The steel combines high mechanical strength (typically up to 600 MPa yield strength) and good ductility with outstanding corrosion resistance to marine environments and a wide, diverse range of oil & gas production environments. A182-F55 is supplied with a PREN (Pitting Resistance Equivalent) at >= 40.0 which guarantees high resistance to pitting corrosion.

We have following production equipment to produce all our F55 forged material

Vacuum Induction Melting (VIM)

Argon Oxygen Decarburization (AOD)

Vacuum Arc Remelting (VAR)

Electro Slag Remelting (ESR)

Hydraulic Press

Radial Forging Machine

Machining

Weld Overlay

FOllowing is chemical compostion of ASTM A 182 F 55 forged steel rings

Carbon 0.03% Max

Silicon 1.00% Max

Manganese 1.00% Max

Phosphorous 0.035% Max

Sulphur 0.015% Max

Chromium 24.0 – 26.0%

Nickel 6.0 – 8.0%

Molybdenum 3.0 – 4.0%

Copper 0.50 – 1.0%

Nitrogen 0.20 – 0.30%

Tungsten 0.50 – 1.0%

PREn >40

FOllowing is heat treatment way of A182-F55 forgd parts

Anneal – Heat to 1100 – 1140oC ensuring sufficient time is allowed for the centre to achieve furnace temperature and hold for a time commensurate with the ruling section, followed by water quenching.

Following of A182-F55 forging parts heat treatment nechanical property Delivery condition :

Tensile strength 730-930 MPa 105877 - 134885 psi

Proof strength 530 MPa 76870 psi

Modulus of elasticity 200 GPa 29007 ksi

Elongation at break (in 50 mm) 25% 25%

The forging ratio of all our A182-F55 forged bars is minimum 3:1

Microstructure test of A182-F55 forged round bars

The microstructure must be uniform and free from extensive segregation and other inhomogeneity. Determination of grain size has to be performed according to EN ISO 643. Grain size checking of sheets shall be performed to the top and the bottom of a forged bars table for each melt, thickness and heat treatment lot. Sheets shall achieve a mean grain size of 2-6. Grain size checking of bars shall be performed for each melt heat treatment lot. Bars shall achieve a grain size of 5 or coarse

FOllowing is reference production standard and inspection standard of ASTM A182 Grade F55,A182-F55 ,F55 ,ASTM A 182 F 55 forged bars

API6A Specification for Wellhead &Christmas Tree Equipment (ISO 10423)

NACE MR 0175 "Petroleum and natural gas industries-Materials for use in H2S-containing Environments in oil and gas production-All Parts (ISO 15156)"

ASTM A370 Standard Test Methods and Definitions for Mechanical Testing of Steel Products

ASTM E10 Standard Test Method for Brinell Hardness of Metallic Materials

ASTM E140 "Standard Hardness Conversion Tables for Metals Relationship Among Brinell Hardness,

Vickers Hardness,Rockwell Hardness,Superficial Hardness,Knoop Hardness,and Scleroscope Hardness"

ASTM E-18 Rockwell Hardness and Rockwell Superficial Hardness of Metallic Material

ASTM A388/A388M Standard Practice for Ultrasonic Examination of Steel Forgings

ASTM A479/A479 "Standard Specification for Stainless Steel Bars and Shapes for Use in Boilers and Other Pressure Vessels"

ASEM A262 " Standard Practices for Detecting Susceptibility to Intergranular Attack in Austenitic Stainless Steels"

ASTM E428 "Standard Practice for Fabrication and Control of Metal,Other than Aluminum,Reference Blocks Used in Ultrasonic Testing"

ISO 148 Metallic materials -Charpy pendulum impact test (All Parts)

ASTM A 484/A 484M Standard Specification for General Requirements for Stainless Steel Bars,Billets,and Forgings

Welcome your inquiry of ASTM A182 Grade F55,A182-F55 ,F55 ,ASTM A 182 F 55 forging forged steel parts

Following is the shape of ASTM A182 Grade F55,A182-F55 ,F55 ,ASTM A 182 F 55 forging steel material that we could do is:A182-F55 Forged Steel round bars square bars Flat bars Rectangles Bars Rods,ASTM A 182 F 55 Forged forging steel rings seamless rolled rings,ASTM A182 Grade F55 Forged Forging Steel Hubs housing shell Sleeves Bushes Bushing Cases Hollow Bars,ASTM A182 Grade F55 Forged Forging Steel Discs Disks Blocks plates,A182-F55 Forged Forging Steel Pipe Tubes Tubings Piping Shells Casings Case barrels Housings.

Following is forging products of ASTM A182 Grade F55,A182-F55 ,F55 ,ASTM A 182 F 55 material that is used in following industry

ASTM A 182 F 55 forging Forged Drilling Pipes Tubes Drill Rods drill Drilling collar

ASTM A182 Grade F55 Forged Forging Turbine and Compressor Labyrinth Shaft Seals

ASTM A 182 F 55 Forged/Forging Blow Out Blowout Preventer RAM Annular dual Bop Body Bodies Block

ASTM A182 Grade F55 Forged Forging drilling tools,risers,connectors,flexible joint ,seals,flanges gasket

A182-F55 Forged Forging Valve Balls,valve Bonnets,valve Body Bodies ,valve Stems,valve closures, valve seat rings, valve core, valve discs,for H type two way 2‐way one way back pressure valves, ball valve,check valve,gate valve

ASTM A182 Grade F55 Forged Forging Steel nuclear Power

ASTM A 182 F 55 Forged Forging Steel Butterfly Valve Main Shafts Spindles

ASTM A182 Grade F55 Forged Forging Swept branches outlets steel fittings swept saddles

A182-F55 Forged Forging downhole drilling tool Mud Motor Splined Drive shafts,Down hole Electric electrical submersible pumps ESP motor Splined Shaft

ASTM A 182 F 55 Forged Forging Steels Christmas Trees wellhead Spool Body Bodies cylinder

ASTM A182 Grade F55 Forged Forging venturi cone meter Body Bodies Blocks

ASTM A182 Grade F55 Forged Forging Steel gate valves Body Bodies bespoke flat bars

A182-F55 forged steel Flowseal cryogenic High Performance BV Butterfly Valves HPBV shaft

A182-F55 forging steel Oil measurement valve Spool Ultrasonic flow meter bodies Body

ASTM A 182 F 55 Forged Forging Steel double studded adapter flange

ASTM A 182 F 55 Forged Forging Steel integral Mud Flange Flanged outlet Studded crosses

ASTM A182 Grade F55 Forged Forging Steel Casing Heads,Tubing Heads,Casing Hangers,Tubing Hangers,Tubing Spools,Casing Spools,Spacer Spools

ASTM A 182 F 55 Forged Forgig Steel nuclear reactor coolant pump Casing Shells body bodis blocks,nuclear reactor coolant pumps containment seal chamber Rooms,nuclear reactor coolant pumps containment seal chamber Rooms

ASTM A 182 F 55 Forged Forging turbomachinery turbo centrifugal compressor Impeller,Compressor Shrouded Impellers

ASTM A 182 F 55 Forged Forging Steel Forged Single Double Bossed boss Blanks FLANGED BOSSES

ASTM A 182 F 55 Forged Forging Steel PUMP Casing cover.PUMP BARREL,pump impeller,pump shafts, pump housing, pump shells,pump body,pump wear rings,pump case casing.

ASTM A182 Grade F55 Forged Forging forge Steel transition Cone

ASTM A182 Grade F55 Forged Forging Steel Pressure Vessel Reactor Nozzles

A182-F55 forged forging steel pipes tubes shells piping tubing barrels housing, tube sheets,baffle plates, nozzles, channel flanges for boiler, heat exchanger,pressure vessel,reactors, heaters

A182-F55 is described as a super duplex stainless steel with a microstructure of 50:50 austenite and ferrite. The steel combines high mechanical strength (typically up to 600 MPa yield strength) and good ductility with outstanding corrosion resistance to marine environments and a wide, diverse range of oil & gas production environments. A182-F55 is supplied with a PREN (Pitting Resistance Equivalent) at >= 40.0 which guarantees high resistance to pitting corrosion.

We have following production equipment to produce all our F55 forged material

Vacuum Induction Melting (VIM)

Argon Oxygen Decarburization (AOD)

Vacuum Arc Remelting (VAR)

Electro Slag Remelting (ESR)

Hydraulic Press

Radial Forging Machine

Machining

Weld Overlay

FOllowing is chemical compostion of ASTM A 182 F 55 forged steel rings

Carbon 0.03% Max

Silicon 1.00% Max

Manganese 1.00% Max

Phosphorous 0.035% Max

Sulphur 0.015% Max

Chromium 24.0 – 26.0%

Nickel 6.0 – 8.0%

Molybdenum 3.0 – 4.0%

Copper 0.50 – 1.0%

Nitrogen 0.20 – 0.30%

Tungsten 0.50 – 1.0%

PREn >40

FOllowing is heat treatment way of A182-F55 forgd parts

Anneal – Heat to 1100 – 1140oC ensuring sufficient time is allowed for the centre to achieve furnace temperature and hold for a time commensurate with the ruling section, followed by water quenching.

Following of A182-F55 forging parts heat treatment nechanical property Delivery condition :

Tensile strength 730-930 MPa 105877 - 134885 psi

Proof strength 530 MPa 76870 psi

Modulus of elasticity 200 GPa 29007 ksi

Elongation at break (in 50 mm) 25% 25%

The forging ratio of all our A182-F55 forged bars is minimum 3:1

Microstructure test of A182-F55 forged round bars

The microstructure must be uniform and free from extensive segregation and other inhomogeneity. Determination of grain size has to be performed according to EN ISO 643. Grain size checking of sheets shall be performed to the top and the bottom of a forged bars table for each melt, thickness and heat treatment lot. Sheets shall achieve a mean grain size of 2-6. Grain size checking of bars shall be performed for each melt heat treatment lot. Bars shall achieve a grain size of 5 or coarse

FOllowing is reference production standard and inspection standard of ASTM A182 Grade F55,A182-F55 ,F55 ,ASTM A 182 F 55 forged bars

API6A Specification for Wellhead &Christmas Tree Equipment (ISO 10423)

NACE MR 0175 "Petroleum and natural gas industries-Materials for use in H2S-containing Environments in oil and gas production-All Parts (ISO 15156)"

ASTM A370 Standard Test Methods and Definitions for Mechanical Testing of Steel Products

ASTM E10 Standard Test Method for Brinell Hardness of Metallic Materials

ASTM E140 "Standard Hardness Conversion Tables for Metals Relationship Among Brinell Hardness,

Vickers Hardness,Rockwell Hardness,Superficial Hardness,Knoop Hardness,and Scleroscope Hardness"

ASTM E-18 Rockwell Hardness and Rockwell Superficial Hardness of Metallic Material

ASTM A388/A388M Standard Practice for Ultrasonic Examination of Steel Forgings

ASTM A479/A479 "Standard Specification for Stainless Steel Bars and Shapes for Use in Boilers and Other Pressure Vessels"

ASEM A262 " Standard Practices for Detecting Susceptibility to Intergranular Attack in Austenitic Stainless Steels"

ASTM E428 "Standard Practice for Fabrication and Control of Metal,Other than Aluminum,Reference Blocks Used in Ultrasonic Testing"

ISO 148 Metallic materials -Charpy pendulum impact test (All Parts)

ASTM A 484/A 484M Standard Specification for General Requirements for Stainless Steel Bars,Billets,and Forgings

Welcome your inquiry of ASTM A182 Grade F55,A182-F55 ,F55 ,ASTM A 182 F 55 forging forged steel parts