Description

Jiangsu Liangyi is professional manufacturer of 1.4565,X2CrNiMnMoN25-18-6-5,X2CrNiMnMoN251865,X2CrNiMnMoN25.18.6.5 open die forging parts and seamless rolled steel forged rings from china

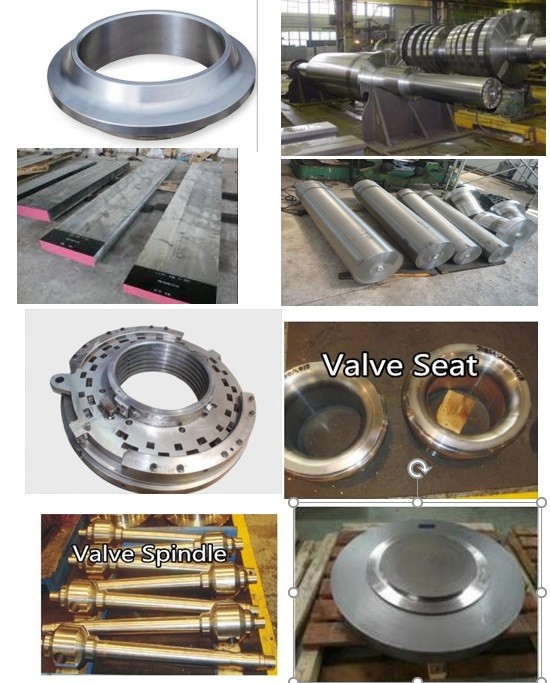

Following is the shape of 1.4565,X2CrNiMnMoN25-18-6-5,X2CrNiMnMoN251865,X2CrNiMnMoN25.18.6.5 forging steel material that we could do is:X2CrNiMnMoN25-18-6-5 Forged Steel round bars square bars Flat bars Rectangles Bars Rods,X2CrNiMnMoN25.18.6.5 Forged forging steel rings seamless rolled rings,1.4565 Forged Forging Steel Hubs housing shell Sleeves Bushes Bushing Cases Hollow Bars,1.4565 Forged Forging Steel Discs Disks Blocks plates,X2CrNiMnMoN25-18-6-5 Forged Forging Steel Pipe Tubes Tubings Piping Shells Casings Case barrels Housings.

Following is forging products of 1.4565,X2CrNiMnMoN25-18-6-5,X2CrNiMnMoN251865,X2CrNiMnMoN25.18.6.5 material that is used in following industry

X2CrNiMnMoN25-18-6-5 Forged Forging Valve Balls,valve Bonnets,valve Body Bodies ,valve Stems,valve closures, valve seat rings, valve core, valve discs,for H type two way 2‐way one way back pressure valves, ball valve,check valve,gate valve

X2CrNiMnMoN25.18.6.5 Forged Forging Steel Butterfly Valve Main Shafts Spindles

1.4565 Forged Forging ship boat Marine Propulsion Shafts Propeller Shaft

X2CrNiMnMoN25-18-6-5 Forged Forging downhole drilling tool Mud Motor Splined Drive shafts,Down hole Electric electrical submersible pumps ESP motor Splined Shaft

1.4565 Forged Forging venturi cone meter Body Bodies Blocks

1.4565 Forged Forging Steel gate valves Body Bodies bespoke flat bars

X2CrNiMnMoN25-18-6-5 forged steel Flowseal cryogenic High Performance BV Butterfly Valves HPBV shaft

X2CrNiMnMoN25.18.6.5 Forged Forgig Steel nuclear reactor coolant pump Casing Shells body bodis blocks,nuclear reactor coolant pumps containment seal chamber Rooms,nuclear reactor coolant pumps containment seal chamber Rooms

X2CrNiMnMoN25.18.6.5 Forged Forging turbomachinery turbo centrifugal compressor Impeller,Compressor Shrouded Impellers

X2CrNiMnMoN25.18.6.5 Forged Forging Steel Forged Single Double Bossed boss Blanks FLANGED BOSSES

X2CrNiMnMoN25.18.6.5 Forged Forging Steel PUMP Casing cover.PUMP BARREL,pump impeller,pump shafts, pump housing, pump shells,pump body,pump wear rings,pump case casing.

1.4565 Forged Forging forge Steel transition Cone

1.4565 Forged Forging Steel Pressure Vessel Reactor Nozzles

X2CrNiMnMoN25-18-6-5 forged forging steel pipes tubes shells piping tubing barrels housing, tube sheets,baffle plates, nozzles, channel flanges for boiler, heat exchanger,pressure vessel,reactors, heaters

1.4565 is a fully austenitic stainless steel which features both, high strength and excellent corrosion resistance in a wide range of corrosive media.

1.4565 is recommended for use especially in equipment for chemical industries. Its resistance to chloride induced pitting and crevice corrosion enables it to be used successfully in the production and transport of oil and gas on on-shore and off-shores facilities. Because of outstanding corrosion resistance, it is very suitable for applications in land-based and in on-board flue gas desulphurization (FGD) systems and other environmental technologies. The performance of Alloy 24 in seawater environments of all kinds, is superior

Following is melting method for 1.4565 forged steel sleeves

1 EAF: Electric Arc Furnace

2 EAF+LF+VD: Refined-smelting and vacuum degassing

3 EAF+ESR: Electro Slag Remelting

4 EAF+PESR: protective atmosphere Electro Slag Remelting

5 VIM+PESR: Vacuum induction meltingR.

Following is production standard of 1.4565,X2CrNiMnMoN25-18-6-5 forging materual

EN 10088-3: 2005 Stainless steels. Technical delivery conditions for semi-finished products, bars, rods, wire, sections and bright products of corrosion resisting steels for general purposes

EN 10088-1: 2005 Stainless steels. List of stainless steels

EN 10088-5: 2009 Stainless steels. Technical delivery conditions for bars, rods, wire, sections and bright products of corrosion resisting steels for construction purposes

FOllowing is chemical compostion of X2CrNiMnMoN25.18.6.5 forged steel rings

C max 0.03

Si max 1

Mn 5 - 7

Ni 16 - 19

P max 0.03

S max 0.015

Cr 24 - 26

Mo 4 - 5

N 0.3 - 0.6

Nb max 0.15

Following of X2CrNiMnMoN25-18-6-5 forging parts heat treatment mechanical property Delivery condition :

Rm - Tensile strength (MPa) (+A) 800-950

Rp0.2 0.2% proof strength (MPa) (+A) 420

KV - Impact energy (J) longitud., +20°100

A - Min. elongation at fracture (%) (+A) 30-35

The quality of Jiangsu products 1.4565,X2CrNiMnMoN25-18-6-5 forging workshop is based on its “state-of-the-art”technology of its laboratories for metallurgy and chemistry. we perform

a range of tests, including mechanical property tests, chemical and environmental analyses, metallographic, macrographic and micrographic tests using optical and electronic microscopes.

, all Ra330 forging steel turbine rotor shafts materials are tested and certified in accordance with nternational standards and Customer’s specifications, using any combination of the following methods: UT-RT-HT-PT-MT-VT-DT

MARKING of our finished forged 1.4565,X2CrNiMnMoN25-18-6-5 bars

Each part shall be stamped with:

The purchaser's part number

The purchaser's purchase number

The individual number

The heat number,if traceability to heat number is not possible by the individual number

The marking shall be surrounded by a frame or painted over with white durable paint.

Welcome your inquiry of 1.4565,X2CrNiMnMoN25-18-6-5,X2CrNiMnMoN251865,X2CrNiMnMoN25.18.6.5 forging forged steel parts