Description

Jiangsu Liangyi professional manufacturer of 1.7375,12CrMo9-10,12CrMo910,12CrMo9.10 open die forging parts and seamless rolled steel forged rings from china

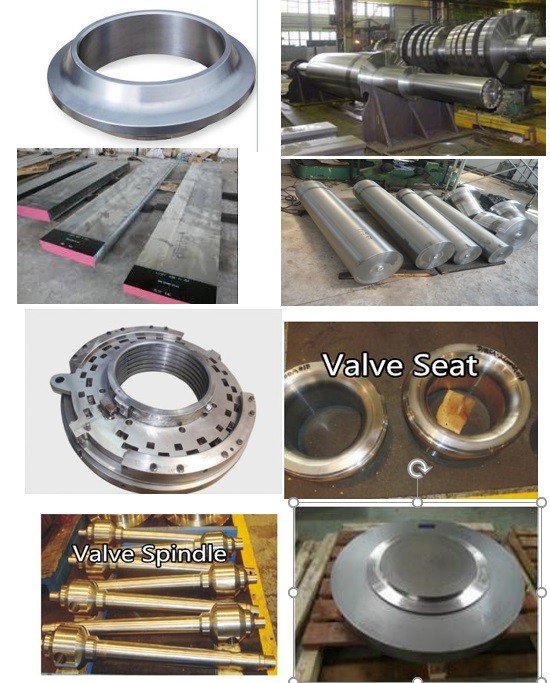

Following is the shape of 1.7375,12CrMo9-10,12CrMo910,12CrMo9.10 forging steel material that we could do is: 1.7375 Forged Steel round bars square bars Flat bars Rectangles Bars Rods,12CrMo9-10 Forged forging steel rings seamless rolled rings,12CrMo9.10 Forged Forging Steel Hubs housing shell Sleeves Bushes Bushing Cases Hollow Bars,1.7375 Forged Forging Steel Discs Disks Blocks plates,12CrMo910 Forged Forging Steel Pipe Tubes Tubings Piping Shells Casings Case barrels Housings.

Following is forging products of 1.7375,12CrMo9-10,12CrMo910,12CrMo9.10 material that is used in following industry

1.7375 Forged Forging Swivel Ring Flanges

12CrMo9-10 Forging/Forged Forge Steel Wye Piece/Piggable Wyes

12CrMo9-10 Forged Forging Swept branches outlets steel fittings swept saddles

12CrMo9-10 forged forging steel pipes tubes shells piping tubing barrels housing, tube sheets, nozzles, channel flanges for boiler, heat exchanger,pressure vessel,reactors, heaters

12CrMo910 Forged Forging Valve Balls,valve Bonnets,valve Body Bodies ,valve Stems,valve closures, valve seat rings, valve core, valve discs,for H type two way 2‐way one way back pressure valves, ball valve,check valve,gate pump

12CrMo910 Forged Forging Steel nuclear Power reactor coolant pumps Rotor Impellers

1.7375 Forged Forging Steel PUMP Casing cover.PUMP BARREL,pump impeller,pump shafts, pump housing, pump shells,pump body,pump wear rings

12CrMo9.10 Forged Forging forge Steel transition Cone

1.7375 Forged Forging Blowout Preventer RAM Annular dual Bops Body Bodies Block

FOllowing is production standard of 1.7375 forged steel material, :

EN 10028-2: 2009 Flat products made of steels for pressure purposes. Non-alloy and alloy steels with specified elevated temperature properties

FOllowing is melting methods for all 12CrMo9-10 forged material as per client choices

1 EAF: Electric Arc Furnace

2 EAF+LF+VD: Refined-smelting and vacuum degassing

3 EAF+ESR: Electro Slag Remelting

4 EAF+PESR: protective atmosphere Electro Slag Remelting

5 VIM+PESR: Vacuum induction melting

FOllowing is chemical compostion of 1.7375, 12CrMo9-10,12CrMo9-10, 12CrMo910 forged steel rings

C 0.1 - 0.15

Si max 0.3

Mn 0.3 - 0.8

Ni max 0.3

P max 0.015

S max 0.01

Cr 2 - 2.5

Mo 0.9 - 1.1

N max 0.012

Al 0.01 - 0.04

Cu max 0.25

Following of 1.7375 forging parts mechanical property :

Nominal thickness (mm): to 250

Rm - Tensile strength (MPa) (+NT) 540-690

Nominal thickness (mm): to 250

ReH - Minimum yield strength (MPa) (+NT) 355

KV - Impact energy (J) transverse, (+NT)

-20°27(J)

0°40 (J)

+20°70(J)

Nominal thickness (mm): to 250

A - Min. elongation at fracture (%) (+NT) 18

FOllowing is inspection standard of 1.7375 Forged steel material

ASTM E 8 Tension Testing of Metallic Materials

ASTM E 8M Tension Testing of Metallic Materials (Metric)

ASTM E 10 Brinell Hardness of Metallic Materials

ASTME 139 Conducting Creep, Creep-Rupture, and Stress-Rupture Tests of Metallic Materials

ASTM E 292 Conducting Time-for-Rupture Notch Tension Tests of Materials

We have following inspection equipment to inspect 1.7375 forging steel parts

Brinell hardness testing for 1.7375 forging parts

Testing of mechanical properties by low and high temperatures for 12CrMo9-10 forging parts

metallography for 1.7375 forging parts

defectoscopy for 1.7375 forged parts

visual testing, dimensional testing for 12CrMo9-10 forging products

UT testing per EN 10228-3 (up to level 4) for 1.7375 forging material

MT testing per EN 10228-1 (up to level 4) for 1.7375 forging parts

Welcome your inquiry of 1.7375, 12CrMo9-10,12CrMo9-10, 12CrMo910 forging forged steel parts

Following is the shape of 1.7375,12CrMo9-10,12CrMo910,12CrMo9.10 forging steel material that we could do is: 1.7375 Forged Steel round bars square bars Flat bars Rectangles Bars Rods,12CrMo9-10 Forged forging steel rings seamless rolled rings,12CrMo9.10 Forged Forging Steel Hubs housing shell Sleeves Bushes Bushing Cases Hollow Bars,1.7375 Forged Forging Steel Discs Disks Blocks plates,12CrMo910 Forged Forging Steel Pipe Tubes Tubings Piping Shells Casings Case barrels Housings.

Following is forging products of 1.7375,12CrMo9-10,12CrMo910,12CrMo9.10 material that is used in following industry

1.7375 Forged Forging Swivel Ring Flanges

12CrMo9-10 Forging/Forged Forge Steel Wye Piece/Piggable Wyes

12CrMo9-10 Forged Forging Swept branches outlets steel fittings swept saddles

12CrMo9-10 forged forging steel pipes tubes shells piping tubing barrels housing, tube sheets, nozzles, channel flanges for boiler, heat exchanger,pressure vessel,reactors, heaters

12CrMo910 Forged Forging Valve Balls,valve Bonnets,valve Body Bodies ,valve Stems,valve closures, valve seat rings, valve core, valve discs,for H type two way 2‐way one way back pressure valves, ball valve,check valve,gate pump

12CrMo910 Forged Forging Steel nuclear Power reactor coolant pumps Rotor Impellers

1.7375 Forged Forging Steel PUMP Casing cover.PUMP BARREL,pump impeller,pump shafts, pump housing, pump shells,pump body,pump wear rings

12CrMo9.10 Forged Forging forge Steel transition Cone

1.7375 Forged Forging Blowout Preventer RAM Annular dual Bops Body Bodies Block

FOllowing is production standard of 1.7375 forged steel material, :

EN 10028-2: 2009 Flat products made of steels for pressure purposes. Non-alloy and alloy steels with specified elevated temperature properties

FOllowing is melting methods for all 12CrMo9-10 forged material as per client choices

1 EAF: Electric Arc Furnace

2 EAF+LF+VD: Refined-smelting and vacuum degassing

3 EAF+ESR: Electro Slag Remelting

4 EAF+PESR: protective atmosphere Electro Slag Remelting

5 VIM+PESR: Vacuum induction melting

FOllowing is chemical compostion of 1.7375, 12CrMo9-10,12CrMo9-10, 12CrMo910 forged steel rings

C 0.1 - 0.15

Si max 0.3

Mn 0.3 - 0.8

Ni max 0.3

P max 0.015

S max 0.01

Cr 2 - 2.5

Mo 0.9 - 1.1

N max 0.012

Al 0.01 - 0.04

Cu max 0.25

Following of 1.7375 forging parts mechanical property :

Nominal thickness (mm): to 250

Rm - Tensile strength (MPa) (+NT) 540-690

Nominal thickness (mm): to 250

ReH - Minimum yield strength (MPa) (+NT) 355

KV - Impact energy (J) transverse, (+NT)

-20°27(J)

0°40 (J)

+20°70(J)

Nominal thickness (mm): to 250

A - Min. elongation at fracture (%) (+NT) 18

FOllowing is inspection standard of 1.7375 Forged steel material

ASTM E 8 Tension Testing of Metallic Materials

ASTM E 8M Tension Testing of Metallic Materials (Metric)

ASTM E 10 Brinell Hardness of Metallic Materials

ASTME 139 Conducting Creep, Creep-Rupture, and Stress-Rupture Tests of Metallic Materials

ASTM E 292 Conducting Time-for-Rupture Notch Tension Tests of Materials

We have following inspection equipment to inspect 1.7375 forging steel parts

Brinell hardness testing for 1.7375 forging parts

Testing of mechanical properties by low and high temperatures for 12CrMo9-10 forging parts

metallography for 1.7375 forging parts

defectoscopy for 1.7375 forged parts

visual testing, dimensional testing for 12CrMo9-10 forging products

UT testing per EN 10228-3 (up to level 4) for 1.7375 forging material

MT testing per EN 10228-1 (up to level 4) for 1.7375 forging parts

Welcome your inquiry of 1.7375, 12CrMo9-10,12CrMo9-10, 12CrMo910 forging forged steel parts