Description

Jiangsu Liangyi is professional manufacturer of AMS 5701,AMS 5702,AMS 5703 open die forging parts and seamless rolled steel forged rings from china

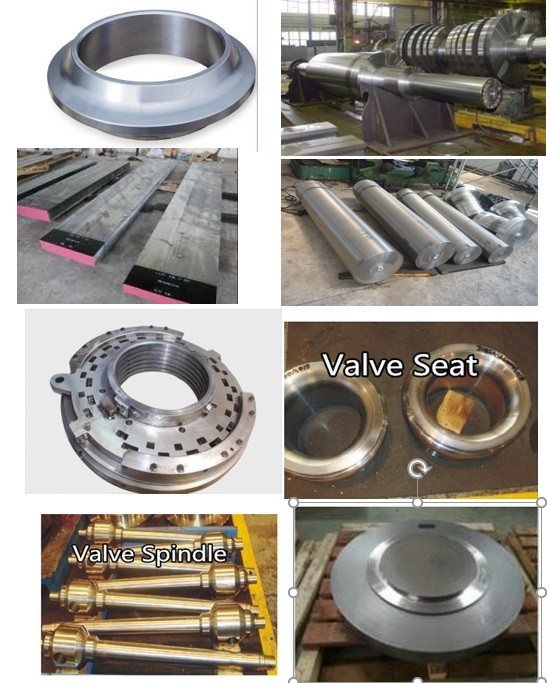

Following is the shape of AMS 5701,AMS 5702,AMS 5703 forging steel material that we could do is:AMS 5703 Forged Steel round bars square bars Flat bars Rectangles Bars Rods,AMS 5701 Forged forging steel rings seamless rolled rings,AMS 5702 Forged Forging Steel Hubs housing shell Sleeves Bushes Bushing Cases Hollow Bars,AMS 5703 Forged Forging Steel Discs Disks Blocks plates,AMS 5703 Forged Forging Steel Pipe Tubes Tubings Piping Shells Casings Case barrels Housings.

Following is forging products of AMS 5701,AMS 5702,AMS 5703 material that is used in following industry

AMS 5702 Forged Forging Turbine and Compressor Labyrinth Shaft Seals

AMS 5701 Forged Forging turbomachinery turbo centrifugal compressor Impeller,Compressor Shrouded Impellers

AMS 5702 Forged Forging Gas Compressor Turbine Blades steel Flat Rectangles Bars

AMS 5702 Forged Forging Gas Compressor Turbine shafts

AMS 5702 Forged Forging Gas steam turbine disks, turbine impeller,turbine blisk,turbine discs,turbine wheel discs,compressor discs

AMS 5701 Forging Steel Forging Forged Gas Steam Turbine Doubled-headed Double end Studs Fasteners Bolts bolting

AMS 5701 Forging Steel gas steam Turbine Guide Rings,Turbine shroud rings,seal rings Labyrinth Rings Packing Seal Diaphragm & Seal Ring Rotor End Rings contours Casing Rings

AMS 5701 Forged Forging Steel Gas Steam turbine diaphragm diapharagm nozzles

AMS 5703 Forged Forging Gas Turbine LPT 1st & 2st 2nd Stg Stage Turbine Case Casings,diffuser cases.

AMS 5703 Forged Forging Steel power plant steam turbine control reheat valve disc Disk

AMS 5703 Forged forging Gas Steam Turbine Valve Spindles/Stems/Rods,

AMS 5703 Forging Steel Gas Steam Turbine MSV/GV/CV/CRV Valve Seats, Valve Cores, Valve Sleeves Spools,,Main Steam Valve Covers Bonnets Sleeves

AMS 5703 is A precipitation-hardening alloy of nickel-chromium-iron, readily fabricated and machinable.

AMS 5703 is widely used in gas turbines for turbine discs, shafts, fasteners, and cases

FOllowing is chemical compostion of AMS 5701,AMS 5702,AMS 5703 forged steel parts

Aluminum 0.4 max

Boron 0.006 max

Carbon 0.06 max

Chromium 14.5 - 17.5

Cobalt 1 max

Copper 0.3 max

Iron Balance

Manganese 0.35 max

Nickel 39 - 44

Niobium 2.5 - 3.5

Phosphorus 0.02 max

Silicon 0.35 max

Sulphur 0.015 max

Titanium 1.5 - 2

FOllowing is mechanical property of AMS 5701,AMS 5702,AMS 5703 forged turbine discs

Properties Metric Imperial

Tensile strength 757 MPa 109800 psi

Yield strength (at strain 0.200%) 383 MPa 55500 psi

Modulus of elasticity (precipitation hardened, dynamic method) 210 GPa 30500 ksi

Elongation at break 47% 47%

All our finished AMS 5703 forged turbine discs will have creep and rupture data, including rupture-strength curve

All our finished AMS 5703 forged parts will have NDT UT & MT result within the mill cert. NDT shall follow below criteria:

NDT Ultrasonic:

· The forging shall not have any UT indication greater than 0.039” (1 mm)

· All detected indications must be separated at least 2” (51 mm) in all directions.

NDT Magnetic Particle

· No linear indications.

· No stringers in excess of 1 mm (0.039”) length in all coupling fits and bearing journals.

· No stringers in disk bores or blade root areas.

· No stringers in excess of 1 mm (0.039”) length in all other areas

The following test methods of AMS 5701,AMS 5702,AMS 5703 forged rings shall be used during delivery inspection.

Tensile testing:EN ISO 6892-1.

Creep rupture testing:ISO 204.

UItrasonic testing shall be carried out in accordance with agreed testing procedure specification.

Macroetching:ASTM A604.

Grain size estimation:ASTM E112

MARKING of our finished forged AMS 5701,AMS 5702,AMS 5703 bars

Each part shall be stamped with:

The purchaser's part number

The purchaser's purchase number

The individual number

The heat number,if traceability to heat number is not possible by the individual number

The marking shall be surrounded by a frame or painted over with white durable paint.

Welcome your inquiry of AMS 5701,AMS 5702,AMS 5703) forging forged steel parts

Following is the shape of AMS 5701,AMS 5702,AMS 5703 forging steel material that we could do is:AMS 5703 Forged Steel round bars square bars Flat bars Rectangles Bars Rods,AMS 5701 Forged forging steel rings seamless rolled rings,AMS 5702 Forged Forging Steel Hubs housing shell Sleeves Bushes Bushing Cases Hollow Bars,AMS 5703 Forged Forging Steel Discs Disks Blocks plates,AMS 5703 Forged Forging Steel Pipe Tubes Tubings Piping Shells Casings Case barrels Housings.

Following is forging products of AMS 5701,AMS 5702,AMS 5703 material that is used in following industry

AMS 5702 Forged Forging Turbine and Compressor Labyrinth Shaft Seals

AMS 5701 Forged Forging turbomachinery turbo centrifugal compressor Impeller,Compressor Shrouded Impellers

AMS 5702 Forged Forging Gas Compressor Turbine Blades steel Flat Rectangles Bars

AMS 5702 Forged Forging Gas Compressor Turbine shafts

AMS 5702 Forged Forging Gas steam turbine disks, turbine impeller,turbine blisk,turbine discs,turbine wheel discs,compressor discs

AMS 5701 Forging Steel Forging Forged Gas Steam Turbine Doubled-headed Double end Studs Fasteners Bolts bolting

AMS 5701 Forging Steel gas steam Turbine Guide Rings,Turbine shroud rings,seal rings Labyrinth Rings Packing Seal Diaphragm & Seal Ring Rotor End Rings contours Casing Rings

AMS 5701 Forged Forging Steel Gas Steam turbine diaphragm diapharagm nozzles

AMS 5703 Forged Forging Gas Turbine LPT 1st & 2st 2nd Stg Stage Turbine Case Casings,diffuser cases.

AMS 5703 Forged Forging Steel power plant steam turbine control reheat valve disc Disk

AMS 5703 Forged forging Gas Steam Turbine Valve Spindles/Stems/Rods,

AMS 5703 Forging Steel Gas Steam Turbine MSV/GV/CV/CRV Valve Seats, Valve Cores, Valve Sleeves Spools,,Main Steam Valve Covers Bonnets Sleeves

AMS 5703 is A precipitation-hardening alloy of nickel-chromium-iron, readily fabricated and machinable.

AMS 5703 is widely used in gas turbines for turbine discs, shafts, fasteners, and cases

FOllowing is chemical compostion of AMS 5701,AMS 5702,AMS 5703 forged steel parts

Aluminum 0.4 max

Boron 0.006 max

Carbon 0.06 max

Chromium 14.5 - 17.5

Cobalt 1 max

Copper 0.3 max

Iron Balance

Manganese 0.35 max

Nickel 39 - 44

Niobium 2.5 - 3.5

Phosphorus 0.02 max

Silicon 0.35 max

Sulphur 0.015 max

Titanium 1.5 - 2

FOllowing is mechanical property of AMS 5701,AMS 5702,AMS 5703 forged turbine discs

Properties Metric Imperial

Tensile strength 757 MPa 109800 psi

Yield strength (at strain 0.200%) 383 MPa 55500 psi

Modulus of elasticity (precipitation hardened, dynamic method) 210 GPa 30500 ksi

Elongation at break 47% 47%

All our finished AMS 5703 forged turbine discs will have creep and rupture data, including rupture-strength curve

All our finished AMS 5703 forged parts will have NDT UT & MT result within the mill cert. NDT shall follow below criteria:

NDT Ultrasonic:

· The forging shall not have any UT indication greater than 0.039” (1 mm)

· All detected indications must be separated at least 2” (51 mm) in all directions.

NDT Magnetic Particle

· No linear indications.

· No stringers in excess of 1 mm (0.039”) length in all coupling fits and bearing journals.

· No stringers in disk bores or blade root areas.

· No stringers in excess of 1 mm (0.039”) length in all other areas

The following test methods of AMS 5701,AMS 5702,AMS 5703 forged rings shall be used during delivery inspection.

Tensile testing:EN ISO 6892-1.

Creep rupture testing:ISO 204.

UItrasonic testing shall be carried out in accordance with agreed testing procedure specification.

Macroetching:ASTM A604.

Grain size estimation:ASTM E112

MARKING of our finished forged AMS 5701,AMS 5702,AMS 5703 bars

Each part shall be stamped with:

The purchaser's part number

The purchaser's purchase number

The individual number

The heat number,if traceability to heat number is not possible by the individual number

The marking shall be surrounded by a frame or painted over with white durable paint.

Welcome your inquiry of AMS 5701,AMS 5702,AMS 5703) forging forged steel parts