Description

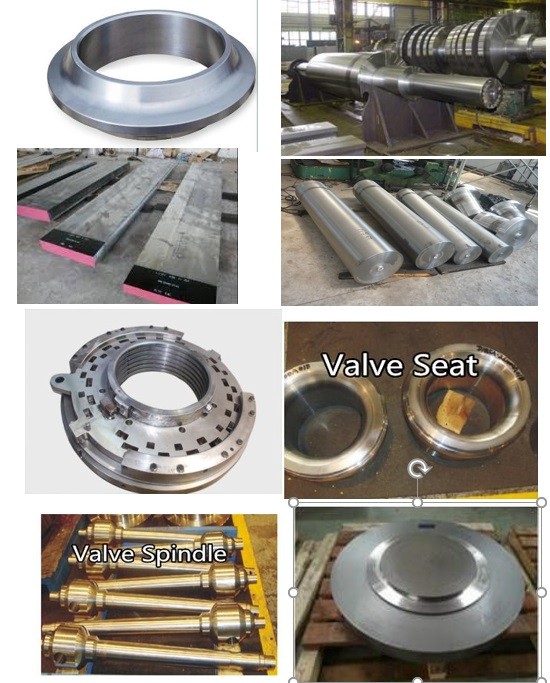

Following is the shape of Inconel 617,Inconel ALloy 617, Alloy 617,UNS N06617 forging steel material that we could do is:Inconel 617 Forged Steel round bars square bars Flat bars Rectangles Bars Rods,Inconel ALloy 617 Forged forging steel rings seamless rolled rings,Alloy 617 Forged Forging Steel Hubs housing shell Sleeves Bushes Bushing Cases Hollow Bars,UNS N06617 Forged Forging Steel Discs Disks Blocks plates,Inconel 617 Forged Forging Steel Pipe Tubes Tubings Piping Shells Casings Case barrels Housings.

Inconel 617 is solid-solution, nickel-chromium-cobalt-molydenum alloy with an exceptional combination of high-temperature strength and oxidation resistance. The alloy also has excellent resistance to a wide range of corrosive environment.

FOllowing is chemical compostion of Inconel ALloy 617 forged steel rings

| Ladle analysis in weight % shall be in accordance with table 4- 1: | ||||||||||||||||||||||||||

| Table 4-1 - Ladle analysis requirements | ||||||||||||||||||||||||||

| C | Si | Mn | P | S | Al | Cr | ||||||||||||||||||||

| 0.05÷0.10 | ≤0.20 | ≤0.20 | ≤0.010 | ≤0.010 | 0.70÷1.40 | 20.00÷23.00 | ||||||||||||||||||||

| Co | Cu | Fe | Mo | Ti | B | Ni | ||||||||||||||||||||

| 11.00÷14.00 | ≤0.50 | ≤2.00 | 8.5÷10.0 | 0.20÷0.60 | ≤0.006 | Balance | ||||||||||||||||||||

Inconel 617 forged parts shall be delivered in solution annealed condition (deliverycondition). Heat treatment shall be performed in following Solution annealing 1150-1200°C Cooling:Air or faster

The values of temperature and time as does the type of cooling medium shall be considered as preferential guidelines.

Following of Inconel 617 forging parts heat treatment nechanical property Delivery condition :

Mechanical properties of inconel 617 forged bars shall be tested on samples cut away from rolled and forged parts in the delivery condition."

"Specimens shall be sampled according to EN 10302 from products belonging to the same delivery lot and to the same melt with the same specified nominal dimensions, subjected to the same manufacturing process and finishing treatment."

| Table 6-1 Specimens mechanical requirements at room temperature | ||||||||||||||||||||||||||

|

Delivery conditions |

tR(1) [mm] |

Rp0.2 [MPa] |

Rm [MPa] |

A [%] (L0=5.65√S0 or L0=5d) |

KV [J] |

|||||||||||||||||||||

| Hot FORGED PLATES | ≤50 | ≥300 | ≥700 | ≥35 | ≥80(2) | |||||||||||||||||||||

| FORGED Bars | ≤200 | ≥300 | ≥700 | ≥30 | ≥80(2) | |||||||||||||||||||||

| 200÷320 | ≥270 | ≥650 | ≥30 | ≥80(2) | ||||||||||||||||||||||

|

1 2 |

tR coincides with: . thickness, for sheets and plates; . diameter, for round bars; . parameter b for other products as defined and shown in EN 10302, Average value of 3 specimens; minimum single value 56 J. |

|||||||||||||||||||||||||

In case, due to technical reasons, it is not possible to extract standard notch impact test specimens, the specimens width shall be reduced to 5 mm. With these specimens impact energy

shall be greater or equal to 40 J (average value of 3 specimens; minimum single value 28 J). For inconel 617 forged flat bars thicknesses <5 mm and bars diameter <16 mm, the impact energy determination can be omitted.

Microstructure test of inconel 617 forged round bars

The microstructure must be uniform and free from extensive segregation and other inhomogeneity. Determination of grain size has to be performed according to EN ISO 643. Grain size checking of sheets shall be performed to the top and the bottom of a forged bars table

for each melt, thickness and heat treatment lot. Sheets shall achieve a mean grain size of 2-6. Grain size checking of bars shall be performed for each melt heat treatment lot. Bars shall achieve a grain size of 5 or coarser.

On each part, non-destructive examinations shall be carried out and certified after the final heat treatment (delivery conditions). Surface condition shall be such to ensure a satisfactory detection of flaws. Following NDT shall be performed in delivery conditions:

Visual inspection;

UT inspection;

Repair welding is not allowed.

Visual test shall be performed according to EN 13018.

Ultrasonic test according to SAE AMS 2154, class B, shall be performed on raw stock or on:

forged flat bars with thickness greater than or equal to 10 mm

, forged round bars bars with diameter greater than or equal to 15 mm

ALl our inconel 617 forged bars shall issue a certificate of test according to SAE AMS 2154 and EN 10204, cert. 3.1

An inspection certificate 3.1 according EN 10204 of our inconel 617 forged bars should have following

purchase order, item, serial n°, drawing number and number of the technical purchasing

specification

material designation

heat n° and heat analysis

method of melting

manufacturing procedure

heat treatment: cooling method (rates and mean of cooling) and measured temperatures.

All heat treatment conditions have to be quoted in a graphic temperature against time

sequence (including all re-heat-treatments). Reports including only average holding

temperatures and times are acceptable.

results of metallographic analysis

mechanical tests certificates, including single values

results and recording of NDT. A dedicated certificate for each performed NDT is required

dimensional report (tabular or graphically) complete of a certificate of compliance

Alloy 617 Forged Forging Turbine and Compressor Labyrinth Shaft Seals

Inconel 617 Forged Forging Valve Balls,valve Bonnets,valve Body Bodies ,valve Stems,valve closures, valve seat rings, valve core, valve discs,for H type two way 2‐way one way back pressure valves, ball valve,check valve,gate valve

ALloy 617 Forged Forging Steel nuclear Power reactor coolant pumps Rotor Impellers

Alloy 617 Forged Forging venturi cone meter Body Bodies Blocks

UNS N06617 Forged Forging Steel gate valves Body Bodies bespoke flat bars

Inconel 617 forging steel Oil measurement valve Spool Ultrasonic flow meter bodies Body

Inconel Alloy 617 Forged Forging Steel double studded adapter flange

Inconel Alloy 617 Forged Forgig Steel nuclear reactor coolant pump Casing Shells body bodis blocks,nuclear reactor coolant pumps containment seal chamber Rooms,nuclear reactor coolant pumps containment seal chamber Rooms

Inconel Alloy 617 Forged Forging turbomachinery turbo centrifugal compressor Impeller,Compressor Shrouded Impellers

Inconel Alloy 617 Forged Forging Steel PUMP Casing cover.PUMP BARREL,pump impeller,pump shafts, pump housing, pump shells,pump body,pump wear rings,pump case casing.

Alloy 617 Forged Forging forge Steel transition Cone

UNS N06617 Forged Forging Steel Pressure Vessel Reactor Nozzles

Alloy 617 Forged Forging Gas Compressor Turbine Blades steel Flat Rectangles Bars

Alloy 617 Forged Forging Gas steam turbine disks, turbine impeller,turbine blisk,turbine discs,turbine wheel discs

Inconel Alloy 617 Forging Steel Forging Forged Gas Steam Turbine Doubled-headed Double end Studs Fasteners Bolts bolting

Inconel Alloy 617 Forging Steel gas steam Turbine Guide Rings,Turbine shroud rings,seal rings Labyrinth Rings Packing Seal Diaphragm & Seal Ring Rotor End Rings contours Casing Rings

Inconel Alloy 617 Forged Forging Steel Gas Steam turbine diaphragm diapharagm nozzles

Inconel 617 Forged Forging Gas Turbine LPT 1st & 2st 2nd Stg Stage Turbine Case Casings

Inconel 617 Forged Forging Steel power plant steam turbine control reheat valve disc Disk

UNS N06617 Forged forging Gas Steam Turbine Valve Spindles/Stems/Rods,

Inconel 617 Forging Steel Gas Steam Turbine MSV/GV/CV/CRV Valve Seats, Valve Cores, Valve Sleeves Spools,,Main Steam Valve Covers Bonnets Sleeves

Inconel 617 forged forging steel pipes tubes shells piping tubing barrels housing, tube sheets,baffle plates, nozzles, channel flanges for boiler, heat exchanger,pressure vessel,reactors, heaters

UNS N06617 Forged Forging Nickel Alloy Bore Protector

Welcome your inquiry of Inconel 617,Inconel ALloy 617, Alloy 617,UNS N06617) forging forged steel parts