Description

Jiangsu Liangyi is professional manufacturer of A-286,Alloy A286,UNS S66286 open die forging parts and seamless rolled steel forged rings from china

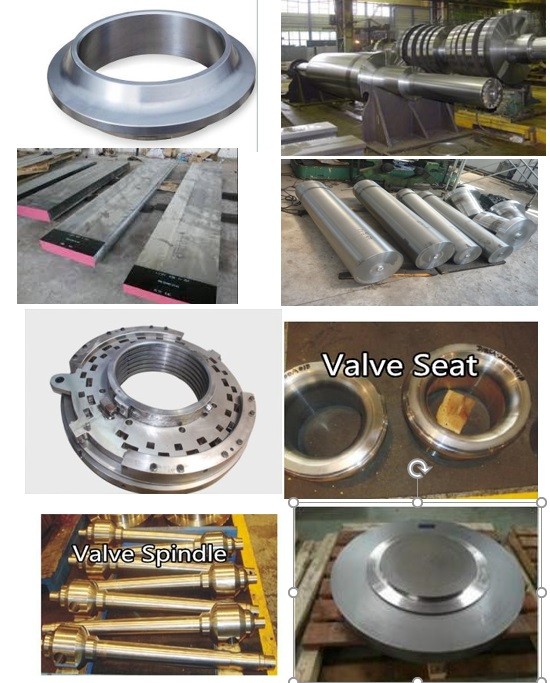

Following is the shape of A-286,Alloy A286,UNS S66286 forging steel material that we could do is:A286 Forged Steel round bars square bars Flat bars Rectangles Bars Rods,Alloy A286 Forged forging steel rings seamless rolled rings,Alloy A286 Forged Forging Steel Hubs housing shell Sleeves Bushes Bushing Cases Hollow Bars,UNS S66286 Forged Forging Steel Discs Disks Blocks plates,A286 Forged Forging Steel Pipe Tubes Tubings Piping Shells Casings Case barrels Housings.

Following is forging products of A-286,Alloy A286,UNS S66286 material that is used in following industry

Alloy A286 forged forging gas separator protector intake HPS splined shaft

forged forging Railway locomotive Traction Motors Non-magnetic Forging Forged Retaining Rings factory

A-286 forged forging Electromagnetic Stirring Rolls Rollers for continuous casting machine

Alloy A286 forging Forged Drilling Pipes Tubes Drill Rods drill Drilling collar

Alloy A286 Forged Forging Turbine and Compressor Labyrinth Shaft Seals

A286 Forging Copper brass Extrusion Dies, extrusion die case

UNS S66286 Forging forged Copper Aluminum Magnesium Extrusion Presses Container Liners Inner Intermediate Liners

Alloy A286 Forged/Forging Blow Out Blowout Preventer RAM Annular dual Bop Body Bodies Block

Alloy A286 Forged Forging drilling tools,risers,connectors,flexible joint ,seals,flanges gasket

A286 Forged Forging Valve Balls,valve Bonnets,valve Body Bodies ,valve Stems,valve closures, valve seat rings, valve core, valve discs,for H type two way 2‐way one way back pressure valves, ball valve,check valve,gate valve

Alloy A286 Forged Forging Steel nuclear Power reactor coolant pumps Rotor Impellers

Alloy A286 Forged Forging Steel Butterfly Valve Main Shafts Spindles

Alloy A286 Forged Forging Swept branches outlets steel fittings swept saddles

A286 Forged Forging downhole drilling tool Mud Motor Splined Drive shafts,Down hole Electric electrical submersible pumps ESP motor Splined Shaft

A286 Forged Forging Gas Air Compressor Rotor

Alloy A286 Forged Forging venturi cone meter Body Bodies Blocks

UNS S66286 Forged Forging Steel gate valves Body Bodies bespoke flat bars

A286 forged steel Flowseal cryogenic High Performance BV Butterfly Valves HPBV shaft

A286 forging steel Oil measurement valve Spool Ultrasonic flow meter bodies Body

Alloy A286 Forged Forging Steel double studded adapter flange

Alloy A286 Forged Forging Steel integral Mud Flange Flanged outlet Studded crosses

UNS S66286 Forged Forging Steel Casing Heads,Tubing Heads,Casing Hangers,Tubing Hangers,Tubing Spools,Casing Spools,Spacer Spools

Alloy A286 Forged Forgig Steel nuclear reactor coolant pump Casing Shells body bodis blocks,nuclear reactor coolant pumps containment seal chamber Rooms,nuclear reactor coolant pumps containment seal chamber Rooms

Alloy A286 Forged Forging turbomachinery turbo centrifugal compressor Impeller,Compressor Shrouded Impellers

Alloy A286 Forged Forging Steel Forged Single Double Bossed boss Blanks FLANGED BOSSES

Alloy A286 Forged Forging Steel PUMP Casing cover.PUMP BARREL,pump impeller,pump shafts, pump housing, pump shells,pump body,pump wear rings,pump case casing.

Alloy A286 Forged Forging forge Steel transition Cone

UNS S66286 Forged Forging Steel Pressure Vessel Reactor Nozzles

Alloy A286 Forged Forging Gas Compressor Turbine Blades steel Flat Rectangles Bars

Alloy A286 Forged Forging Gas steam turbine disks, turbine impeller,turbine blisk,turbine discs,turbine wheel discs

Alloy A286 Forging Steel Forging Forged Gas Steam Turbine Doubled-headed Double end Studs Fasteners Bolts bolting

Alloy A286 Forging Steel gas steam Turbine Guide Rings,seal rings Labyrinth Rings Packing Seal Diaphragm & Seal Ring Rotor End Rings contours Casing Rings

Alloy A286 Forged Forging Steel Gas Steam turbine diaphragm diapharagm nozzles

A286 Forged Forging Gas Turbine LPT 1st & 2st 2nd Stg Stage Turbine Case Casings

A286 Forged Forging Steel power plant steam turbine control reheat valve disc Disk

UNS S66286 Forged forging Gas Steam Turbine Valve Spindles/Stems/Rods,

A286 Forging Steel Gas Steam Turbine MSV/GV/CV/CRV Valve Seats, Valve Cores, Valve Sleeves Spools,,Main Steam Valve Covers Bonnets Sleeves

A286 forged forging steel pipes tubes shells piping tubing barrels housing, tube sheets,baffle plates, nozzles, channel flanges for boiler, heat exchanger,pressure vessel,reactors, heaters

UNS S66286 Forged Forging Nickel Alloy Bore Protector

A-286 is iron-base superalloy useful for applications requiring high strength and corrosion resistance up to 1300°F (704°C) and for lower stress applications at higher temperatures., it is widely used in jet engine components, fasteners and springs that are subjected to temperatures up to 1800ºF, and non-magnetic cryogenic equipment. Exhaust parts, turbines and nozzles utilized in the oil industry require the high tensile strength and good corrosion resistance.

The A-286 forged materials supplied in accordance to this specification shall be produced with the following

processes:

- For A-286 forging parts triple melt material, VIM + ESR + VAR.

- For A286 forged material double melt material, VIM + VAR is acceptable.

For each ingot a sufficient allowance shall be left to ensure absence of sh rinkage cavity or excessive chemical and non -metallic segregation.

The materials supplied according to this specification shall be free from internal and external defects such as to impair the manufacturing and correct operation of the components produced.

The chemical composition of A286 forged material shall be made on samples which correspond to the top & bottom of the re -molten ingot used to the make the part according to ASTM E354, ASTM E1473, ASTM E2465 and ARP1313 for trace elements (lead, bismuth and selenium). Others than abovementioned standards may be used provided THAT they are approved by the purchaser.

Chemical analysis performed on final product shall conform to the variations specified in ASTM B880.

Micrographic characteristics of A286 forged parts

The sampling of metallographic specimens shall be approved by clients.

The optical micrographs shall be taken on polished specimens after etching by Kalling’s reagent at x200 and x500 magnifications.

• Regular microstructure: after the supply heat-treatment, delta phase shall be uniformly distributed with globular and/or rectangular shape;

• Irregular microstructure: the presence of acicular delta phase, stringers/networks of precipitates and sharp edge grains is admitted only if

results of all mechanical properties required by part spec are acceptable

Grain size of A286 forged rings, determined according ASTM E112, shall be as follows:

for turbine use a286 forging parts grain dimension shall be 7 or finer. The maximum size of limited areas, distributed randomly, could be 5.

for other use of a-286 forging parts grain dimension shall be 4 or finer. The maximum size of limited areas, distributed randomly, could be 2.

Transition between zones of different grain size shall be gradual.

In case of inhomogeneous grain size distribution the following information shall be reported:

• average dimension of the two sizes of grain

• % of coarse grain

Individual grains having dimension 2 or finer (ASTM E112) are acceptable if they are surrounded by grain with dimension 7 or finer (necklace structure).

FOllowing is chemical compostion of Alloy A286 forged steel rings

Carbon – 0.08%

Mn Manganese – 2.00%

P Phosphorous – 0.025%

S Sulfur – 0.025%

Si Silicon – 1.00%

Cr Chromium – 13.50 – 16.00%

Ni Nickel – 24.00 – 27.00%

Mo Molybdenum – 1.00 – 1.50%

Ti Titanium – 1.90 – 2.35%

V Vanadium – 0.10 – 0.50%

Al Aluminum – 0.35%

B Boron – 0.003 – 0.010%

Fe Iron - Balance

Following is heat treatment way of A-286 forged material

Solution Heat Treatment:

980ºC ± 10 for > 1 hour, followed by air cool (BS)

1800ºF ± 25 (982 ± 14ºC) 1 hour, water/oil quench (AMS)

Precipitation Heat Treatment:

720ºC ± 10 > 16 hours, followed by air cool (BS)

1300-1400 ºF (704-760ºC) hold not less 16 hours, air cool (AMS)

Following of A286 forging parts heat treatment nechanical property Delivery condition :

Alloy 0.2 Proof Stress (min) Tensile Strength (min) Elongation (min)

Alloy A286 Solution Treated and Aged 590 N/mm² 900 N/mm² 13%

Alloy A286 Solution Treated and Aged 85 ksi (586 mpa) 130 ksi (896 mpa) 15%

Mechanical properties Tests of A286 forged bars are to be performed according to ASTM E8, ASTM E21, ASTM E10, ASTM E606, ASTM E647, ASTM E399 and ASTM E292.

Any test bar not meeting minimum property requirements shall require re -testing. If the original test bar fails due to a clear special cause (e.g. test machine failure) one re-test is required.

The re -tested bar shall meet minimum property requirements and the result must be reported.

If the original test bar does not meet minimum property requirements and a well-defined cause is not found, then two re -tests are required. All retested bars shall meet the requirements; all test results, including the original one, shall be reported.

Bars for re -test shall be taken from the same part as the initial test bar, provided the re -tested section is immediately adjacent to the initial test location and it has approximately equal thickness. If this is not possible, retest bars shall be taken from the same location of another part belonging to the same master heat and heat treatment lot

Qualification of manufacturing procedure of A286 forging parts

The Manufacturing Process Plan (MPP) shall be submitted to the approval of clients Material

& Process Engineering dept. clients before qualification procedure begins. It shall detail at least

the following:

• type of ingot (supplier, manufacturing process, dimensions, and tests to beperformed);

• forging process;

• heat treatment process;

• tests on component.

In general, dissection of the first piece within the terms detailed in the part specification is required.

This activity may be omitted, upon decision of clients, if the supplier has already proven to be able to successfully produce components of similar shape, dimensions and manufacturing

process.

Welcome your inquiry of A286,Alloy A286, Alloy A286,UNS S66286) forging forged steel parts