Description

Jiangsu Liangyi is professional manufacturer of HAYNES HR-160,UNS N12160,ALloy HR160 open die forging parts and seamless rolled steel forged rings from china

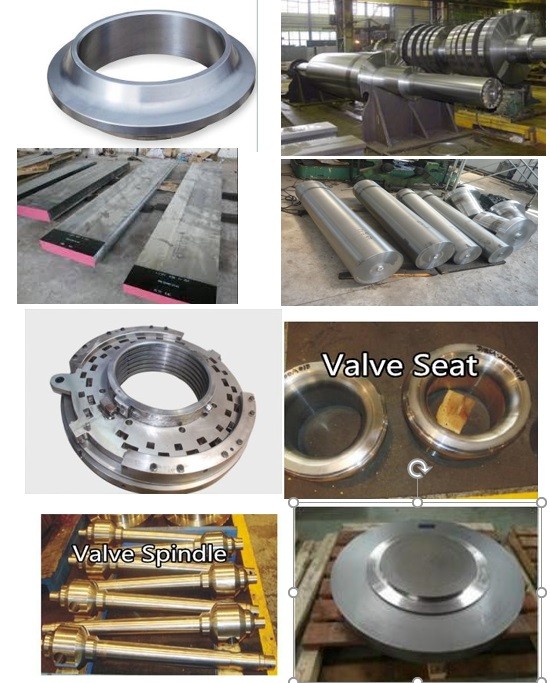

Following is the shape of HAYNES HR-160,UNS N12160,ALloy HR160 forging steel material that we could do is:HAYNES HR-160 Forged Steel round bars square bars Flat bars Rectangles Bars Rods,Cobalt Alloy 25 Forged forging steel rings seamless rolled rings,UNS N12160 Forged Forging Steel Hubs housing shell Sleeves Bushes Bushing Cases Hollow Bars,UNS N12160 Forged Forging Steel Discs Disks Blocks plates,HAYNES HR160/ Forged Forging Steel Pipe Tubes Tubings Piping Shells Casings Case barrels Housings.

Following is forging products of HAYNES HR-160,UNS N12160,ALloy HR160 material that is used in following industry

HAYNES HR-160 Forged Forging Gas Compressor Turbine Blades steel Flat Rectangles Bars

HAYNES HR160 Forged Forging Gas steam turbine disks, turbine impeller,turbine blisk,turbine discs

HAYNES HR-160 forged forging steel pipes tubes shells piping tubing barrels housing, tube sheets,baffle plates, nozzles, channel flanges for boiler, heat exchanger,pressure vessel,reactors, heaters

UNS N12160 Forging Steel Forging Forged Gas Steam Turbine Doubled-headed Double end Studs Fasteners Bolts bolting

UNS N12160 forged forging bearings and bearing races rings

ALloy HR160 Forging Steel gas steam Turbine Guide Rings,seal rings Labyrinth Rings Packing Seal Diaphragm & Seal Ring Rotor End Rings contours Casing Rings

UNS N12160 Forged Forging Steel Gas Steam turbine diaphragm diapharagm nozzles

UNS N12160 Forged Forging Gas Turbine LPT 1st & 2st 2nd Stg Stage Turbine Case Casings

HAYNES HR-160 Forged Forging Steel power plant steam turbine control reheat valve disc Disk

HAYNES HR-160 Forged forging Gas Steam Turbine Valve Spindles/Stems/Rods,

HAYNES HR-160 Forging Steel Gas Steam Turbine MSV/GV/CV/CRV Valve Seats, Valve Cores, Valve Sleeves Spools,,Main Steam Valve Covers Bonnets Sleeves

Forged HR-160 thermocouple protection tubes for waste incineration and chemical process facilities

HAYNES HR-160 forged material for nuclear power such as :Flow limiter Venturi forgings (steam generator),Forged tubes for pressurizer surge line,reactor nozzles and primary pump fly wheels, divider plates for steam generator,Latch housings, rod travel housings and funnel extension,end ring and rotor stack plate forgings,bearing housings and stator end cap and closure ring forgings,Containment plates, rings and closure heads,Waste Flasks and Mounting Skirt,RPV Upper Shell and HSG Shell,Shell Strakes and Transition Cones,Pressure Components,Lifting Pin Tools and Trunnions,Pressuriser Upper Head and Upper Shell,Steam Drumhead and Lifting Pintle

HAYNES HR-160 is a heat resistant alloy with exceptional resistance to the most common forms of high temperature corrosion. This resistance is obtained by a high content of chromium and silicon which provides the alloy with a tightly closed oxide film, giving it a very high protection against sulfur, chlorine, vanadium and other salt deposits.

HAYNES HR-160 have following Applications include a variety offabricated components inmunicipal, industrial, hazardous, and nuclear waste incinerators. It is widely used inrecuperators, heat exchangers and waste heat recovery

systems. HR-160 alloy is also suitable for utility boilers, sulfur plants, high-temperature furnaces, kilns, calciners,

resource recovery units, cement kilns, pulp and paper recovery boilers, coal gasification systems, and fluidized-bed combustion systems.

Forgings HAYNES HR-160 maeterial shall be manufactured from steel produced by vacuum induction melting 1 electro-slag re-melting {VIM/ESR) or by vacuum induction melting 1 vacuum are re-melting (VIM/VAR) process.

The hot working shall be done in such a way that a uniform fine grained microstructure is achieved.

The HAYNES HR-160 forged material shall undergo the following heat treatment:

HAYNES HR-160 is solution annealed at 2050°F (1121°C) and rapidly cooled for optimum properties. Intermediate annealing, if required during fabrication and forming operations, can be

performed at temperatures as low as 1950°F (1066°C). HR-160® alloy is furnished in the

solution annealed condition, unless otherwise specified.

The forgings HAYNES HR-160 forged parts shall be free from defects such as cracks, flakes, seams, segregation, non-metallic inclusionsand other defects which may affect the utility of the forgings.

Chemical composition of HAYNES HR-160,UNS N12160,ALloy HR160 forging turbine parts is as

Nickel (Ni) 25 to 44.4

Cobalt (Co) 27 to 33

Chromium (Cr) 26 to 30

Silicon (Si) 2.4 to 3.0

Iron (Fe) 0 to 3.5

Manganese (Mn) 0 to 1.5

Molybdenum (Mo) 0 to 1.0

Tungsten (W) 0 to 1.0

Niobium (Nb) 0 to 1.0

Titanium (Ti) 0.2 to 0.8

Carbon (C) 0 to 0.15

Phosphorus (P) 0 to 0.030

Sulfur (S) 0 to 0.015

mechanical property of for HAYNES HR-160,UNS N12160,ALloy HR160 forged round bars is as follow

Tensile strength, σb/≥ MPa: 724

Yield strength, σ0.2/≥ MPa: 321

Elonghation, δ ≥(%): 66

.

We have following forging production equipment for all our HAYNES HR-160,UNS N12160,ALloy HR160 forging steel parts

6 mobile hearth heating furnaces with a loading capacity of 10t up to 80t, equipped with a centralized automatic controlled system of the heating cycles;

a 6.300 tons semiautomatic hydraulic press;

a 3.500 tons semiautomatic hydraulic press;

a 70 tons capacity manipulator;

a 36 tons capacity manipulator;

a 24 tons capacity manipulator;

a 12 tons manipulator on rails.

The capacity of our a wide range of 1.4548 forging parts is in different shapes and sizes, weighing up to 35 tons.

We have following heat treatment equipment for all our HAYNES HR-160,UNS N12160,ALloy HR160 forging material

21 gas furnaces with a loading capacity of 20t up to 80t and a max length of 16m;

1 electric furnaces with a max capacity of 20 tons;

2 130 and 200 m3 quenching tanks filled with water;

2 110 and 200 m3 quenching tanks filled with water and a polymer solution.

All furnaces are equipped with an automatic programming system controlled by a centralized computer with a heat treatment cycle recording system.

Quenching tanks are equipped with an automatic cooling system which keeps the liquid within the temperature requested.

Welcome your inquiry of HAYNES HR-160,UNS N12160,ALloy HR160 forging parts