Description

Jiangsu Liangyi is professional manufacturer of Stainless Steel AMS 5655 open die forging parts and seamless rolled steel forged rings,forging steel gas steam turbine blade steel flat bars from china

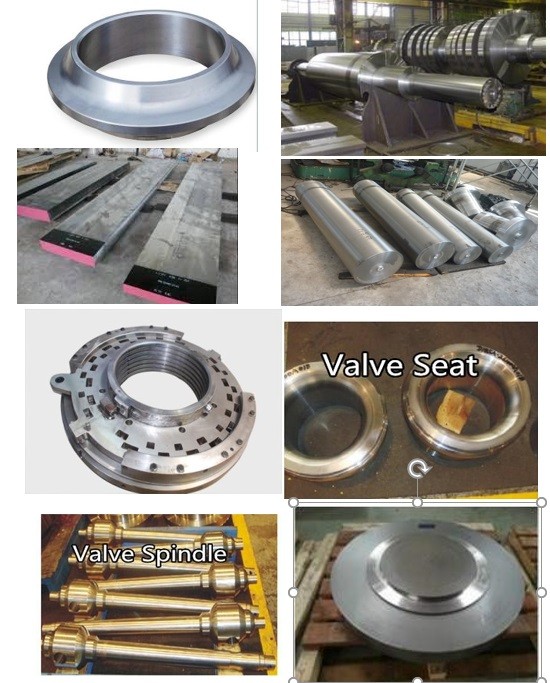

Following is the shape of AMS 5655 forging steel material that we could do is:Stainless Steel AMS 5655 Forged Steel round bars square bars Flat bars Rectangles Bars Rods,AMS 5655 Forged forging steel rings seamless rolled rings,AMS 5655 Forged Forging Steel Hubs housing shell Sleeves Bushes Bushing Cases Hollow Bars,AMS 5655 Forged Forging Steel Discs Disks Blocks plates,AMS 5655 Forged Forging Steel Pipe Tubes Tubings Piping Shells Casings Case barrels Housings.

Following is forging products of AMS 5655 that is used in gas steam turbine

AMS 5655 Forged Forging Steel Gas Steam Turbine blade steel

AMS 5655 forged forging steel gas steam turbine rotor shafts

AMS 5655 Forged Forging Gas Compressor Turbine Blades steel Flat Rectangles Bars

AMS 5655 Forged Forging Steel Gas Steam turbine diaphragm diapharagm nozzles

AMS 5655 Forged Forging Steel gas steam Turbine Guide Rings,seal rings Labyrinth Rings Packing Seal Diaphragm & Seal Ring Rotor End Rings contours Casing Rings/Blade Fitting Rings

AMS 5655 Forging Forged Steel Gas Turbine Wheels Discs turbine impeller turbine blisks

AMS 5655 Forged Forging Gas Turbine LPT 1st & 2st 2nd Stg Stage Turbine Case Casings

AMS 5655 Forged Forging Rolled Steel Gas Turbine LPT 1st & 2st 2nd Stg Stage Steam Turbine shrouds turbines journal and thrust bearing

AMS 5655 Forged Forging Steel power plant steam turbine control reheat valve disc Disk

AMS 5655 Forged forging Gas Steam Turbine Valve Spindles/Stems/Rods,

AMS 5655 Forging Forged Gas Steam Turbine Doubled-headed Double end Studs Fasteners Bolts

AMS 5655 Forging Steel Gas Steam Turbine MSV/GV/CV/CRV Valve Seats, Valve Cores, Valve Sleeves Spools,,Main Steam Valve Covers Bonnets Sleeves

AMS 5655 Forged Forging Steel Gas Steam Turbine Oil Guards nozzle Bearing Gland Seal Sealing Rings,

AMS 5655 forging Steam Gas Turbine Inlet Guide Vane IGV Control Ring Lower Upper Half,Outer Inner Transition Ducts,

AMS 5655 forged Forged Forging Rolled Gas Steam Turbine Inner Outer Heat Shields,

AMS 5655 is AOD + ESR melted grade with additional heavy metal alloying elements giving it good strength and temper resistance at higher temperatures up to 1200oF. Similar to the 410 stainless this grade has the ability to be heat treated to multiple different strength levels. Because of the temper resistance this alloy is often used in the power generation market as steam and gas turbine components or various other high heat components , AMS 5665 is also popular material within the aerospace and defence industries that boasts impressive mechanical properties, such as high strength, toughness, and corrosion resistance. This precipitation-hardening stainless steel alloy is well-suited for critical applications requiring reliable, long-lasting performance in extreme environments. In addition, AMS5655 is known for its excellent weldability, which makes it a go-to choice for precision parts and components in complex systems. Whether you’re designing aircraft engines or missile systems, AMS 5655 offers the strength and durability needed to ensure your products perform flawlessly in challenging conditions. AMS 5655 is widely used in ,the aerospace industry for manufacturing of high-temperature bolting, valves, and valve trim, and also in steam turbines for buckets and blades.,landing gear, engine components, and fasteners in the aerospace industry. In the oil and gas industry, it is used for drilling components, valves, and pumps. Steel is also used in defence applications, such as armoured vehicles, tanks, and missile components.

Chemical composition % of steel AMS 5665 forged steel round bars:

Iron (Fe)Iron, Fe ~ 82

Chromium, Cr 11.0-13.0

Manganese, Mn 1.00

Nickel, Ni 0.5-1.0

Molybdenum, Mo 0.75-1.25

Tungsten, W 0.75-1.25

Silicon, Si 0.75

Carbon, C 0.20-0.25

Vanadium, V 0.15-0.3

Phosphorous, P 0.025

Sulfur, S 0.025

Mechanical properties of steel AMS 5665 forging steel rings

0.2 % Yield Strength (ksi) MIn 140

Ultimate Tensile Strength (ksi) % Min 115

Elongation in 2" % min 13

Reduction of Area Min 25

Hardness HB 293-341

We have following inspection equipment to inspect of all our AMS 5665 forging steel gas steam turbine parts

a well equipped chemical lab which carries out test analysis on the steel heats made in the steel mill

a well equipped lab which carries out mechanical tensile & resilience tests as well as creep tests

a metallurgic lab for structural macro-micro and inclusion micro metallurgic examinations, according to ISO 17025

non destructive UT/MP/LP tests carried out by experienced and qualified SNT-TA-1A operators

fixed and portable Brinell/3000/10 hardness check equipment

dedicated and certified equipment for dimensional controls.

All our forged AMS 5665 forged gas turbine parts can be release en10204-3.1 certificate, or en10204-3.2 inspection certificate from following third party,3.2 mit TUV ,GL BV,DNV,ABS ,Lloyds Register of Shipping, RMRS ,RINA and so on