Description

Jiangsu Liangyi is professional manufacturer of 2.4668,NiCr19Fe19Nb5Mo3 open die forging parts and seamless rolled steel forged rings from china

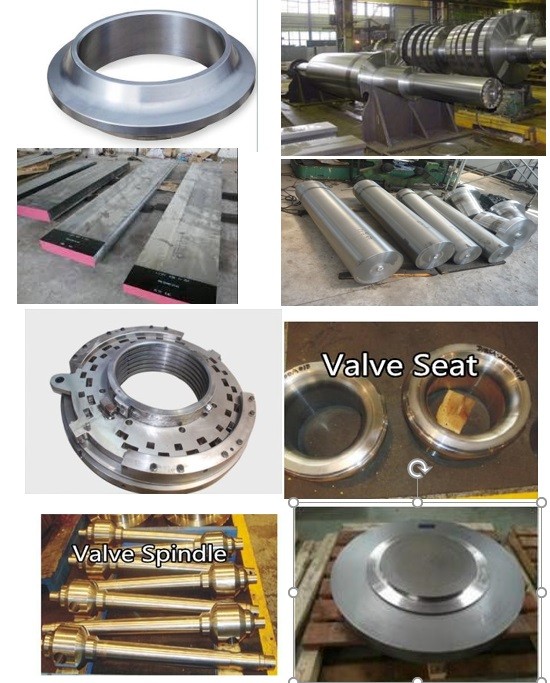

Following is the shape of 2.4668,NiCr19Fe19Nb5Mo3 forging steel material that we could do is:2.4668 Forged Steel round bars square bars Flat bars Rectangles Bars Rods,2.4668 Forged forging steel rings seamless rolled rings,2.4668 Forged Forging Steel Hubs housing shell Sleeves Bushes Bushing Cases Hollow Bars,NiCr19Fe19Nb5Mo3 Forged Forging Steel Discs Disks Blocks plates,NiCr19Fe19Nb5Mo3 Forged Forging Steel Pipe Tubes Tubings Piping Shells Casings Case barrels Housings.

2.4668 is a high-strength, corrosion-resistant nickel chromium material used at -423º to 1300ºF (-217º to 704ºC). The age-hardenable alloy can be readily fabricated, even into complex parts. Its welding characteristics, especially its resistance to postweld cracking, are oustanding. The ease and economy with which 2.4668 can be fabricated, combined with good tensile, fatigue, creep, and rupture strength, have resulted in its use in a wide range of applications.

2.4668 is most often used for aicraft components (turbine engine parts, high-speed airframe parts, such as wheels, buckets, spacers; high-temperature bolts and fasteners), in industrial gas turbines, cryogenic tankage, and nuclear engineering.Other popular uses are high strength bolting and down hole shafting.

Chemical composition of 2.4668,NiCr19Fe19Nb5Mo3 forging turbine parts is as

Element Min Max

C - 0.08

Si - 0.35

Mn - 0.35

P - 0.015

Al 0.2 0.8

B - 0.6

Co - 1

Cr 17 21

Cu - 0.3

Fe Balance

Mo 2.8 3.3

Nb 4.75 5.5

Ni 50 55

Ti 0.65 1.15

Following is heat treatment way of 2.4668,NiCr19Fe19Nb5Mo3 forged parts

The following heat treatment should be used to obtain the best combination of tensile properties and stress rupture properties:

1 hr 1750°F to 1800°F (954 to 982°C) air cool + 8hr 1325°F (718°C) cool 100°F /hr to 1150°F (56 °C/hr to 621°C), hold 8 hrs and air cool.

To obtain the best room temperature and cryogenic tensile properties, the following heat treatment should be used:

1 to 2 hr 1950°F (1066°C), air cool + 8 hr 1325°F (718°C) cool 100°F/hr to 1150°F (56°C/hr to 621°C), hold 8 hr and air cool.

mechanical property of for 2.4668,NiCr19Fe19Nb5Mo3 forged round bars is as follow

Rm - Tensile strength (MPa) (+AT) 1230

Rp0.2 0.2% proof strength (MPa) (+AT) 1030

A - Min. elongation at fracture (%) (+AT) 12

All documentation of finished 2.4668 forging material inspection document must be written in English.

All results must be given in accordance with the Sl system.

All documentation shall be well readable without risk of incorrect interpretation.

Inspection certificate EN 10204-3.1,with heat analysis and results of all testing in accordance with 6 Delivery inspection.

Heat treatment certificate,with information on the temperature and soaking time. 2-3 Surplus test material shall be separated from the blank and stored by the supplier for a minimum of three month after accepted delivery.If the test material is to be delivered,this will be stated in the purchase order or in a separate message.

A“Declaration of conformity”in accordance with EN ISO/IEC 17050 may be accepted as reporting,if this is stated in an agreement with the purchaser.

The declaration shall contain:

All information necessary for full tracking to delivered goods and/or process used.

- Reference to all inspection and test reports.

ALl our 2.4668 forging material shall file all subordinated documents at least 15 years after the delivery of the goods or the service.

Following is inspection standard of 2.4668 forged parts

ASTM A604 Standard test methods for macroetch testing of consumable electrode

remelted steel bars and billets

ASTM E112 Standard test methods for determining average grain size

EN ISO 6892-1:20 Metallic materials -Tensile testing -Part 1:Method of test at ambient temperature

ISO 204:2009 Metallic materials -Uniaxial creep testing in tension -Method of test

EN 10204 Metallic products -Types of inspection documents

EN ISO/IEC 17050:2004 Conformity assessment -Supplier's declaration of conformity -General requirements

All our 2.4668 forged material must give the material a required purity necessary for the application in following melting methods

one is triple melted material,VIM+ESR+VAR., the another one is double melted material,VIM+VAR.

All our 2.4668 forging material shall be thoroughly worked,homogenous and free from blisters, cracks and injurious slag inclusions.

Following is forging products of 2.4668, NiCr19Fe19Nb5Mo3 material that is used in following industry

2.4668 forged forging gas separator protector intake HPS splined shaft

2.4668 forging Forged Drilling Pipes Tubes Drill Rods drill Drilling collar

2.4668 Forged Forging Turbine and Compressor Labyrinth Shaft Seals

2.4668 Forging Copper brass Extrusion Dies, dies case,extrusion stems,

NiCr19Fe19Nb5Mo3 Forging forged Copper Aluminum Magnesium Extrusion Presses Container Liners Inner Intermediate Liners

2.4668 Forged/Forging Blow Out Blowout Preventer RAM Annular dual Bop Body Bodies Block

2.4668 Forged Forging drilling tools,risers,connectors,flexible joint ,seals,flanges gasket

2.4668 Forged Forging Valve Balls,valve Bonnets,valve Body Bodies ,valve Stems,valve closures, valve seat rings, valve core, valve discs,for H type two way 2‐way one way back pressure valves, ball valve,check valve,gate valve

2.4668 Forged Forging Steel nuclear Power reactor coolant pumps Rotor Impellers

2.4668 forged steel Mechanical Seal Discs

2.4668 Forged Forging Steel Butterfly Valve Main Shafts Spindles

2.4668 Forged Forging Swept branches outlets steel fittings swept saddles

2.4668 Forged Forging downhole drilling tool Mud Motor Splined Drive shafts,Down hole Electric electrical submersible pumps ESP motor Splined Shaft

2.4668 Forged Forging Gas Air Compressor Rotor

Forged Forging Gas Steam Turbine Engine Tie Rods

2.4668 Forged Forging Steels Christmas Trees wellhead Spool Body Bodies cylinder

2.4668 Forged Forging venturi cone meter Body Bodies Blocks

NiCr19Fe19Nb5Mo3 Forged Forging Steel gate valves Body Bodies bespoke flat bars

2.4668 forged steel Flowseal cryogenic High Performance BV Butterfly Valves HPBV shaft

2.4668 forging steel Oil measurement valve Spool Ultrasonic flow meter bodies Body

2.4668 Forged Forging Steel double studded adapter flange

2.4668 Forged Forging Steel integral Mud Flange Flanged outlet Studded crosses

NiCr19Fe19Nb5Mo3 Forged Forging Steel Casing Heads,Tubing Heads,Casing Hangers,Tubing Hangers,Tubing Spools,Casing Spools,Spacer Spools

2.4668 Forged Forgig Steel nuclear reactor coolant pump Casing Shells body bodis blocks,nuclear reactor coolant pumps containment seal chamber Rooms,nuclear reactor coolant pumps containment seal chamber Rooms

2.4668 Forged Forging turbomachinery turbo centrifugal compressor Impeller,Compressor Shrouded Impellers

2.4668 Forged Forging Steel Forged Single Double Bossed boss Blanks FLANGED BOSSES

2.4668 Forged Forging Steel PUMP Casing cover.PUMP BARREL,pump impeller,pump shafts, pump housing, pump shells,pump body,pump wear rings,pump case casing.

2.4668 Forged Forging forge Steel transition Cone

NiCr19Fe19Nb5Mo3 Forged Forging Steel Pressure Vessel Reactor Nozzles

2.4668 Forged Forging Gas Compressor Turbine Blades steel Flat Rectangles Bars

2.4668 Forged Forging Gas steam turbine disks, turbine impeller,turbine blisk,turbine discs,turbine wheel discs

2.4668 Forging Steel Forging Forged Gas Steam Turbine Doubled-headed Double end Studs Fasteners Bolts bolting

2.4668 Forging Steel gas steam Turbine Guide Rings,seal rings Labyrinth Rings Packing Seal Diaphragm & Seal Ring Rotor End Rings contours Casing Rings

2.4668 Forged Forging Steel Gas Steam turbine diaphragm diapharagm nozzles

2.4668 Forged Forging Gas Turbine LPT 1st & 2st 2nd Stg Stage Turbine Case Casings

2.4668 Forged Forging Steel power plant steam turbine control reheat valve disc Disk

NiCr19Fe19Nb5Mo3 Forged forging Gas Steam Turbine Valve Spindles/Stems/Rods,

2.4668 Forging Steel Gas Steam Turbine MSV/GV/CV/CRV Valve Seats, Valve Cores, Valve Sleeves Spools,,Main Steam Valve Covers Bonnets Sleeves

2.4668 forged forging steel pipes tubes shells piping tubing barrels housing, tube sheets,baffle plates, nozzles, channel flanges for boiler, heat exchanger,pressure vessel,reactors, heaters

NiCr19Fe19Nb5Mo3 Forged Forging Nickel Alloy Bore Protector

Welcome your inquiry of 2.4668,NiCr19Fe19Nb5Mo3 forging parts

Following is the shape of 2.4668,NiCr19Fe19Nb5Mo3 forging steel material that we could do is:2.4668 Forged Steel round bars square bars Flat bars Rectangles Bars Rods,2.4668 Forged forging steel rings seamless rolled rings,2.4668 Forged Forging Steel Hubs housing shell Sleeves Bushes Bushing Cases Hollow Bars,NiCr19Fe19Nb5Mo3 Forged Forging Steel Discs Disks Blocks plates,NiCr19Fe19Nb5Mo3 Forged Forging Steel Pipe Tubes Tubings Piping Shells Casings Case barrels Housings.

2.4668 is a high-strength, corrosion-resistant nickel chromium material used at -423º to 1300ºF (-217º to 704ºC). The age-hardenable alloy can be readily fabricated, even into complex parts. Its welding characteristics, especially its resistance to postweld cracking, are oustanding. The ease and economy with which 2.4668 can be fabricated, combined with good tensile, fatigue, creep, and rupture strength, have resulted in its use in a wide range of applications.

2.4668 is most often used for aicraft components (turbine engine parts, high-speed airframe parts, such as wheels, buckets, spacers; high-temperature bolts and fasteners), in industrial gas turbines, cryogenic tankage, and nuclear engineering.Other popular uses are high strength bolting and down hole shafting.

Chemical composition of 2.4668,NiCr19Fe19Nb5Mo3 forging turbine parts is as

Element Min Max

C - 0.08

Si - 0.35

Mn - 0.35

P - 0.015

Al 0.2 0.8

B - 0.6

Co - 1

Cr 17 21

Cu - 0.3

Fe Balance

Mo 2.8 3.3

Nb 4.75 5.5

Ni 50 55

Ti 0.65 1.15

Following is heat treatment way of 2.4668,NiCr19Fe19Nb5Mo3 forged parts

The following heat treatment should be used to obtain the best combination of tensile properties and stress rupture properties:

1 hr 1750°F to 1800°F (954 to 982°C) air cool + 8hr 1325°F (718°C) cool 100°F /hr to 1150°F (56 °C/hr to 621°C), hold 8 hrs and air cool.

To obtain the best room temperature and cryogenic tensile properties, the following heat treatment should be used:

1 to 2 hr 1950°F (1066°C), air cool + 8 hr 1325°F (718°C) cool 100°F/hr to 1150°F (56°C/hr to 621°C), hold 8 hr and air cool.

mechanical property of for 2.4668,NiCr19Fe19Nb5Mo3 forged round bars is as follow

Rm - Tensile strength (MPa) (+AT) 1230

Rp0.2 0.2% proof strength (MPa) (+AT) 1030

A - Min. elongation at fracture (%) (+AT) 12

All documentation of finished 2.4668 forging material inspection document must be written in English.

All results must be given in accordance with the Sl system.

All documentation shall be well readable without risk of incorrect interpretation.

Inspection certificate EN 10204-3.1,with heat analysis and results of all testing in accordance with 6 Delivery inspection.

Heat treatment certificate,with information on the temperature and soaking time. 2-3 Surplus test material shall be separated from the blank and stored by the supplier for a minimum of three month after accepted delivery.If the test material is to be delivered,this will be stated in the purchase order or in a separate message.

A“Declaration of conformity”in accordance with EN ISO/IEC 17050 may be accepted as reporting,if this is stated in an agreement with the purchaser.

The declaration shall contain:

All information necessary for full tracking to delivered goods and/or process used.

- Reference to all inspection and test reports.

ALl our 2.4668 forging material shall file all subordinated documents at least 15 years after the delivery of the goods or the service.

Following is inspection standard of 2.4668 forged parts

ASTM A604 Standard test methods for macroetch testing of consumable electrode

remelted steel bars and billets

ASTM E112 Standard test methods for determining average grain size

EN ISO 6892-1:20 Metallic materials -Tensile testing -Part 1:Method of test at ambient temperature

ISO 204:2009 Metallic materials -Uniaxial creep testing in tension -Method of test

EN 10204 Metallic products -Types of inspection documents

EN ISO/IEC 17050:2004 Conformity assessment -Supplier's declaration of conformity -General requirements

All our 2.4668 forged material must give the material a required purity necessary for the application in following melting methods

one is triple melted material,VIM+ESR+VAR., the another one is double melted material,VIM+VAR.

All our 2.4668 forging material shall be thoroughly worked,homogenous and free from blisters, cracks and injurious slag inclusions.

Following is forging products of 2.4668, NiCr19Fe19Nb5Mo3 material that is used in following industry

2.4668 forged forging gas separator protector intake HPS splined shaft

2.4668 forging Forged Drilling Pipes Tubes Drill Rods drill Drilling collar

2.4668 Forged Forging Turbine and Compressor Labyrinth Shaft Seals

2.4668 Forging Copper brass Extrusion Dies, dies case,extrusion stems,

NiCr19Fe19Nb5Mo3 Forging forged Copper Aluminum Magnesium Extrusion Presses Container Liners Inner Intermediate Liners

2.4668 Forged/Forging Blow Out Blowout Preventer RAM Annular dual Bop Body Bodies Block

2.4668 Forged Forging drilling tools,risers,connectors,flexible joint ,seals,flanges gasket

2.4668 Forged Forging Valve Balls,valve Bonnets,valve Body Bodies ,valve Stems,valve closures, valve seat rings, valve core, valve discs,for H type two way 2‐way one way back pressure valves, ball valve,check valve,gate valve

2.4668 Forged Forging Steel nuclear Power reactor coolant pumps Rotor Impellers

2.4668 forged steel Mechanical Seal Discs

2.4668 Forged Forging Steel Butterfly Valve Main Shafts Spindles

2.4668 Forged Forging Swept branches outlets steel fittings swept saddles

2.4668 Forged Forging downhole drilling tool Mud Motor Splined Drive shafts,Down hole Electric electrical submersible pumps ESP motor Splined Shaft

2.4668 Forged Forging Gas Air Compressor Rotor

Forged Forging Gas Steam Turbine Engine Tie Rods

2.4668 Forged Forging Steels Christmas Trees wellhead Spool Body Bodies cylinder

2.4668 Forged Forging venturi cone meter Body Bodies Blocks

NiCr19Fe19Nb5Mo3 Forged Forging Steel gate valves Body Bodies bespoke flat bars

2.4668 forged steel Flowseal cryogenic High Performance BV Butterfly Valves HPBV shaft

2.4668 forging steel Oil measurement valve Spool Ultrasonic flow meter bodies Body

2.4668 Forged Forging Steel double studded adapter flange

2.4668 Forged Forging Steel integral Mud Flange Flanged outlet Studded crosses

NiCr19Fe19Nb5Mo3 Forged Forging Steel Casing Heads,Tubing Heads,Casing Hangers,Tubing Hangers,Tubing Spools,Casing Spools,Spacer Spools

2.4668 Forged Forgig Steel nuclear reactor coolant pump Casing Shells body bodis blocks,nuclear reactor coolant pumps containment seal chamber Rooms,nuclear reactor coolant pumps containment seal chamber Rooms

2.4668 Forged Forging turbomachinery turbo centrifugal compressor Impeller,Compressor Shrouded Impellers

2.4668 Forged Forging Steel Forged Single Double Bossed boss Blanks FLANGED BOSSES

2.4668 Forged Forging Steel PUMP Casing cover.PUMP BARREL,pump impeller,pump shafts, pump housing, pump shells,pump body,pump wear rings,pump case casing.

2.4668 Forged Forging forge Steel transition Cone

NiCr19Fe19Nb5Mo3 Forged Forging Steel Pressure Vessel Reactor Nozzles

2.4668 Forged Forging Gas Compressor Turbine Blades steel Flat Rectangles Bars

2.4668 Forged Forging Gas steam turbine disks, turbine impeller,turbine blisk,turbine discs,turbine wheel discs

2.4668 Forging Steel Forging Forged Gas Steam Turbine Doubled-headed Double end Studs Fasteners Bolts bolting

2.4668 Forging Steel gas steam Turbine Guide Rings,seal rings Labyrinth Rings Packing Seal Diaphragm & Seal Ring Rotor End Rings contours Casing Rings

2.4668 Forged Forging Steel Gas Steam turbine diaphragm diapharagm nozzles

2.4668 Forged Forging Gas Turbine LPT 1st & 2st 2nd Stg Stage Turbine Case Casings

2.4668 Forged Forging Steel power plant steam turbine control reheat valve disc Disk

NiCr19Fe19Nb5Mo3 Forged forging Gas Steam Turbine Valve Spindles/Stems/Rods,

2.4668 Forging Steel Gas Steam Turbine MSV/GV/CV/CRV Valve Seats, Valve Cores, Valve Sleeves Spools,,Main Steam Valve Covers Bonnets Sleeves

2.4668 forged forging steel pipes tubes shells piping tubing barrels housing, tube sheets,baffle plates, nozzles, channel flanges for boiler, heat exchanger,pressure vessel,reactors, heaters

NiCr19Fe19Nb5Mo3 Forged Forging Nickel Alloy Bore Protector

Welcome your inquiry of 2.4668,NiCr19Fe19Nb5Mo3 forging parts