Description

Jiangsu Liangyi professional manufacturer of 17H11MFNb(18Ch11MNFB,18Х11МНФБ,2Х11МФБН) open die forging parts and forged steel gas steam turbine turbine blade vane steel ,turbo generator,Turbomachines,Turbomachinery,turbogenerator forging steel turbine rotor shafts factory from china

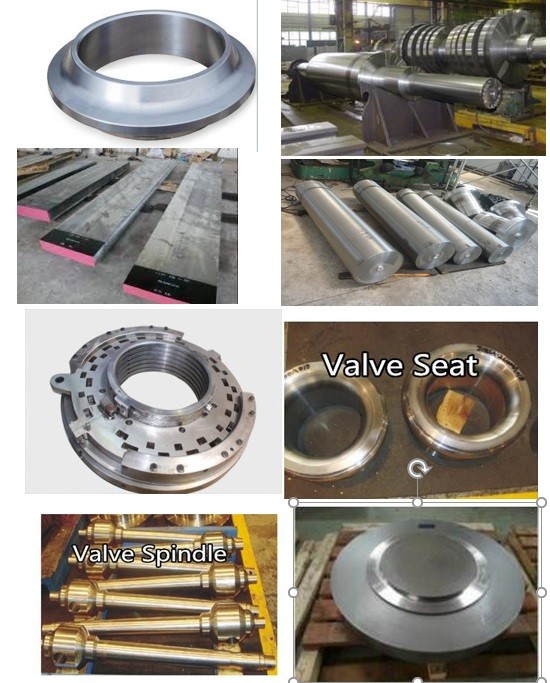

Following is the shape of 17H11MFNb(18Ch11MNFB,18Х11МНФБ,2Х11МФБН) Forging steel material that we could do is:17H11MFNb Forged Steel round bars square bars Flat bars Rectangles Bars Rods, 18Х11МНФБ Forged forging steel rings seamless rolled rings, 18Ch11MNFB Forged Forging Steel Hubs housing shell Sleeves Bushes Bushing Cases Hollow Bars,18Х11МНФБ Forged Forging Steel Discs Disks Blocks plates, 2Х11МФБН Forged Forging Steel Pipe Tubes Tubings Piping Shells Casings Case barrels Housings. 2Х11МФБН Forged Forging Steel Gas Steam Turbine Rotors Shafts,2Х11МФБН Forged Forging Gas Compressor Turbine Blades turbine Vane steel Flat Rectangles Bars, 18Х11МНФБ Forged Forging Steel gas steam Turbine Guide Rings,seal rings Labyrinth Rings Packing Seal Diaphragm & Seal Ring Rotor End Rings contours Casing Rings,,2Х11МФБН Forged forging Gas Steam Turbine Valve Spindles/Stems/Rods,17H11MFNb Forging Forged Gas Steam Turbine Doubled-headed Double end Studs Fasteners Bolts

17H11MFNb(18Ch11MNFB,18Х11МНФБ,2Х11МФБН) is Corrosion resistant high temperature martensitic steel for power engineering, turbine blades, bolts and nuts

FOllowing is production standard of 18Х11МНФБ

ГОСТ 2591-2006; ГОСТ 1133-71; ГОСТ 2879-2006; ГОСТ 2590-2006;ГОСТ 103-2006;ГОСТ 19442-74; ГОСТ 18968-73; ГОСТ 14955-77; ГОСТ 5949-75; ГОСТ 7417-75; ГОСТ 8559-75

Chemical composition for 17H11MFNb(18Ch11MNFB,18Х11МНФБ,2Х11МФБН) forged steel gas turbine blade steel as follows

(C): 0,15 - 0,21

(Si): до 0,6

(Mn): 0,6 - 1

(Ni): 0,5 -1

(S): до 0,025

(P): до 0,03

(Cr): 10 - 11,5

(Mo): 0,8 - 1,1

(V): 0,2 - 0,4

(Nb): 0,2 - 0,45

The following properties of 17H11MFNb(18Ch11MNFB,18Х11МНФБ,2Х11МФБН) forging turbine blade flat bars at room temperature must be demonstrated by the following tests

18Х11МНФБ forged Bar, GOST 5949-75 tensile strength Min 740 Yield strength 590-735 Elongation min 15 Reduction minimum 50 Heat treatment way is Quenching 1080 - 1130oC, air, then 660 - 770oC, air,

18Х11МНФБ forging flat Bar, GOST 18968-75 tensile strength min 740 Yield strength 590-735 Elongation min 15 Reduction minimum 50 heat treatment way is Normalizing and drawing

Brinell hardness for 18KH11MNFB ( 18Х11МНФБ ) forged blade steel flat bars (annealing) , Bar GOST 5949-75 HB 10 -1 = 225 MPa

Brinell hardness for 18KH11MNFB ( 18Х11МНФБ ) forging round bars (normalize, tempering) , Bar GOST 18968-73 HB 10 -1 = 229 - 269 MPa

Characteristics of heat-resistant sheet 18Х11МНФБ-Ш forged steel blade steel,environmental friendliness;resistance to mechanical, thermal and chemical influences;resistant to corrosion;long service life.

our 17H11MFNb(18Ch11MNFB,18Х11МНФБ,2Х11МФБН) forging turbine blade is normally used in following gas steam turbine for Applications in the energy sector,Fossil,Coal-fired power plants,Gas-fired power plant,Combined cycle power plants,Geothermal