Description

Jiangsu Liangyi professional manufacturer of ASTM A182-F91,ASME SA182 F91,ASME SA336 F91 ,ASME SA336 P91,A 335 Grade P91 - SA 355 Grade P91 , ASTM A 182 F 91 open die forging parts and seamless rolled steel forged rings from china

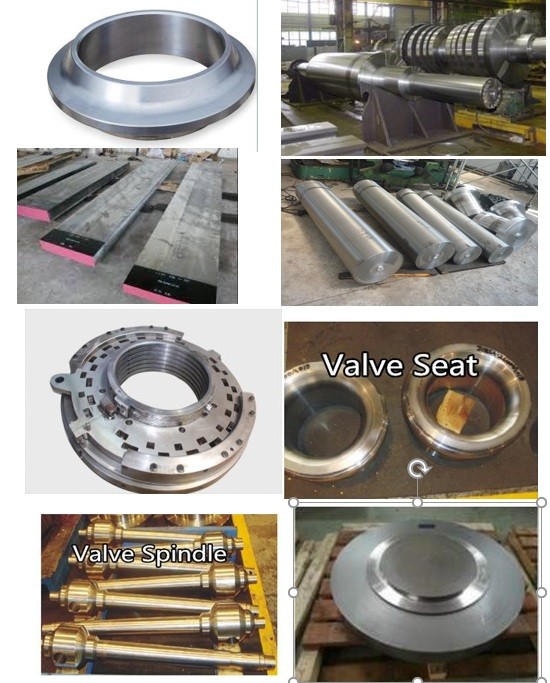

Following is the shape of ASTM A182-F91,ASME SA182 F91,ASME SA336 F91 ,ASME SA336 P91 forging steel material that we could do is:ASTM A182-F91 Forged Steel round bars square bars Flat bars Rectangles Bars Rods,ASME SA182 F91 Forged forging steel rings seamless rolled rings,ASME SA336 F91 Forged Forging Steel Hubs housing shell Sleeves Bushes Bushing Cases Hollow Bars,ASME SA336 P91 Forged Forging Steel Discs Disks Blocks plates,ASTM A 182-F91 Forged Forging Steel Pipe Tubes Tubings Piping Shells Casings Case barrels Housings.

Following is forging products of ASTM A182-F91 that is used in following industry

ASTM A182-F91, Forginbg forged steel valve body,valve bonnet.valve closure, valve seat rings, valve stems, valve discs disks for High pressure gate valves,High pressure globe valves, High Pressure Swing Check valve,High pressure valves steam turbine power valves, GAs TURBINE BYPASS VALVE,Line blind valves,Preheater bypass valve

ASME SA182 F91 forged forging steel pipes tubes shells piping tubing barrels housing, tube sheets, nozzles, channel flanges for boiler, heat exchanger,pressure vessel

F91 Forging Steel Gas Steam Turbine MSV/GV/CV/CRV Valve Seats, Valve Cores, Valve Sleeves Spools,,Main Steam Valve Covers Bonnets Sleeves

ASME SA182 F91 forging/forged Steel Lateral Tees T-piece Wyes( Lateral Y-Piece, Eccentric Lateral Tee)

P91 Forged Forged Pumps suction side sealing jacket seal chambers jacket casings

F91 Forged Forging Swivel Ring Flanges

ASME SA182 F91 Forging/Forged Forge Steel Wye Piece/Piggable Wyes

A 335 Grade P91 Forged Forging Swept branches outlets steel fittings swept saddles

F91 Forged Forging Steel double studded adapter flange

ASTM A182-F91 Forged Forging venturi cone meter Body Bodies Blocks

ASME SA336 F91 forging steel Oil measurement valve Spool Ultrasonic flow meter bodies Body

ASME SA182 F91 Forged Forging Steel double studded adapter flange

A 335 Grade P91 Forged Forging Steel integral Mud Flange Flanged outlet Studded crosses

ASTM A182-F91 Forged Forgig Steel nuclear reactor coolant pump Casing Shells body bodis blocks,nuclear reactor coolant pumps containment seal chamber Rooms,nuclear reactor coolant pumps containment seal chamber Rooms

A182-F91 Forged Forging Steel Pressure Vessel STUDDING OUTLET

F91 Forged Forging Steel PUMP Casing cover.PUMP BARREL,pump impeller,pump shafts, pump housing, pump shells,pump body,pump wear rings

ASTM A182-F91 Forged Forging forge Steel transition Cone

A182-F91 is AN ALLOY STEEL WITH CHROME AND AN ADDITION OF NB, WHICH HAS ELEVATED MECHANICAL CHARACTERISTICS AND IT IS VERY OFTEN USED IN THE CHEMICAL AND PETROCHEMICAL INDUSTRIES FOR THE FABRICATION OF FLANGES, VALVES, TUBES AND FOR EQUIPMENTS THAT REQUIRE AN EXCELLENT CREEP RESISTANCE AND TO EMBRITTLEMENT BECAUSE OF HYDROGEN UNDER PRESSURE AND AT AN ELEVATED TEMPERATURE (UP TO 600°C)., It is most Steel used for production of boiler components with supercritical and ultra-critical parameters - jackets, connectors for F91 forged steel steam superheater outlet chambers, superheated steam superheaters, F91 forging steel turbine shaft parts, P91 forging chambers and pipelines for fresh and superheated steam, superheater coils, steam collectors, outlet collectors, fittings and sleeves for the installation of boilers, connectors, pipelines of modern power units operating at temperatures of approximately 550-640C and steam pressures of approx. 18-30 MPa.

FOllowing is normal name for F91 forging steel parts:

A 336 GRADE F91, SA 336 GRADE F91, A 336 GRADE F911, SA 336 GRADE F911, A 336 GRADE FP91, A 387 GRADE 91, SA 387 GRADE 91, A182 F91, A200 T91, A182 F911, SA182 F911, SA335 GRADE P911, A335 GRADE P91, A691 GRADE 91, SA335 GRADE P91.

The A182-F91 forged material shall be melted by an electric furnace process (E) and post treated by argon oxygen decarburization (AOD) / Vacuum Oxygen Decarburization (VOD). The steel shall be fully killed.

FOllowing is chemical compostion of ASME SA182 F91 forging shells

C: 0,08 - 0,12 %

Cr: 8,0 - 9,5 %

Mn: 0,3 - 0,6 %

Mo: 0,85 - 1,05 %

Ni: max. 0,4 %

P: max. 0,025 %

S: max. 0,015 %

Si: max. 0,5 %

V: 0,18 - 0,25 %

N: 0,03 - 0,07 %

Al: max. 0,04 %

Folllowing is mechanical property of ASME SA182 F91 forging steel pipes

0,2% Yield strength Rp0,2 (N/mm2) >=450

Yield strength Mpa MIn 415

Tensile strength Rm(N/mm2) 620-850

Elongation-A5 (%)min. >=20

impact strength (J) (transverse) MIn 40

Tensile strength Rm N/mm2 MIn 585

Mechanical testing of F91 forged bars

Scope of testing

For each test unit and each test location, the following tests shall be carried out:

Microsection, longitudinal with photo picture (500:1)

Tensile test at 20°C (±5°) according EN ISO 6892- 1 [9] (test method A)

Hot tensile test according EN ISO 6892-2 [10] at design temperature (±5°) – if no information is indicated, the hot tensile test shall be performed at 350°C (±5°).

Impact test according EN ISO 148- 1 [11] on 3 Charpy V-notch test samples at 20°C (±5°).

Test units, locations and direction of test samples of F91 forged bars

Product form

Test unit1) for microsection, tensile test

and impact test at 20°C

Test unit for hot

tensile test

Sampling location and

direction

Forgings

Each melting charge, dimension and heat

treatment lot

Each melting

charge

According EN10222- 1

[1]

Rolled bars

According EN 10273 [3]

The following table shows preliminary reference values for the 1 % creep limit properties and stress rupture properties of F91 forged parts. The values in the following table are average values of all available (scattering range) records. Based on the available records of all long-term tests up to now, it may be expected, that the lower limit of the scattering range, at the assigned temperature , will be 20% under the stated (average-)value.

|

Temperature [°C] |

1 % creep limit | Stress rupture properties | ||||||||||||||||||||||||||

|

104 h [Mpa] |

for 105 h [Mpa] |

|||||||||||||||||||||||||||

|

104 h [Mpa] |

105 h [Mpa] |

205 h [Mpa] |

||||||||||||||||||||||||||

| 470 | 323 | 277 | 356 | 317 | --- | |||||||||||||||||||||||

| 480 | 298 | 256 | 332 | 295 | --- | |||||||||||||||||||||||

| 490 | 274 | 232 | 309 | 274 | --- | |||||||||||||||||||||||

| 500 | 253 | 213 | 289 | 255 | 245* | |||||||||||||||||||||||

| 510 | 231 | 193 | 270 | 236 | 225* | |||||||||||||||||||||||

| 520 | 212 | 177 | 251 | 217 | 206* | |||||||||||||||||||||||

| 530 | 193 | 161 | 233 | 199 | 188 | |||||||||||||||||||||||

| 540 | 177 | 145 | 216 | 182 | 170 | |||||||||||||||||||||||

| 550 | 161 | 132 | 200 | 164 | 153 | |||||||||||||||||||||||

| 560 | 147 | 119 | 183 | 148 | 136 | |||||||||||||||||||||||

| 570 | 133 | 107 | 167 | 132 | 121 | |||||||||||||||||||||||

| 580 | 121 | 97 | 152 | 117 | 106 | |||||||||||||||||||||||

| 590 | 109 | 86 | 137 | 103 | 93 | |||||||||||||||||||||||

| 600 | 98 | 77 | 122 | 90 | 81 | |||||||||||||||||||||||

| 610 | 88 | 68 | 109 | 79 | 71 | |||||||||||||||||||||||

| 620 | 79 | 61 | 97 | 70 | 63 | |||||||||||||||||||||||

| 630 | 70 | --- | 86 | 62 | 56* | |||||||||||||||||||||||

| 640 | 62 | --- | 76 | 55 | 49* | |||||||||||||||||||||||

| 650 | 56 | --- | 68 | 48 | 43* | |||||||||||||||||||||||

| 660 | --- | --- | 61** | 42** | 36** | |||||||||||||||||||||||

| 670 | --- | --- | 54** | 36* and ** | --- | |||||||||||||||||||||||

|

* Extrapolation ** Only for information |

||||||||||||||||||||||||||||

| Middle linear thermal expansion coefficient at 20°C of F91 forged parts | ||||||||||||||||||||||||||||

| The values as following are only guidelines. | ||||||||||||||||||||||||||||

| Between 20 °C und temperature …..°C | 50 | 100 | 200 | 300 | 400 | 500 | 550 | 600 | 650 | |||||||||||||||||||

| Thermal expansion coefficient [10-6 K-1] | 10.5 | 10.7 | 11.1 | 11.5 | 11.9 | 12.3 | 12.5 | 12.6 | 12.7 | |||||||||||||||||||

| Tensile modules of P91 forged bars | ||||||||||||||||||||||||||||

| The values as following are only guidelines. | ||||||||||||||||||||||||||||

| Temperature in °C | 20 | 50 | 100 | 200 | 300 | 400 | 500 | 550 | 600 | 650 | ||||||||||||||||||

| E-modul [GPa] | 217 | 215 | 212 | 207 | 200 | 191 | 181 | 174 | 167 | 158 | ||||||||||||||||||

Heat treatment way of ASTM A182-F91,ASME SA182 F91 forged parts

| Quenching and tempering | Heat treatment after welding | |||||||||||||||||||||||||||

| Hardening | Tempering | |||||||||||||||||||||||||||

|

1040 °C to 1080 °C 1) Cooling in oil |

>760 °C to ≤ 780 °C Holding time (EN 10052 [12]): 2 min per 1mm thickness, minimum 60 min. Cooling on air |

740 °C to 770 °C Holding time (EN 10052 [12]): 2 min. per 1mm thickness, minimum 60 min. Cooling on air |

||||||||||||||||||||||||||

| 1) For (quenching-) thickness < 80mm, cooling on air with controlled atmosphere may be possible. | ||||||||||||||||||||||||||||