Description

Jiangsu Liangyi professional manufacturer of 1.6962,25NiCrMoV12.7,25NiCrMoV12-7,25NiCrMoV127 open die forging parts and forged steel gas steam turbine turbine rotor shafts from china

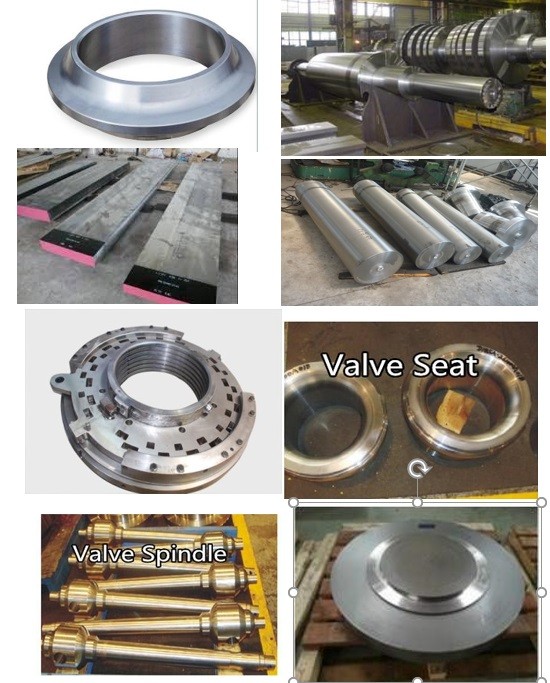

Following is the shape of 1.6962,25NiCrMoV12.7,25NiCrMoV12-7,25NiCrMoV127 Forging steel material that we could do is:25NiCrMoV12.7 Forged Steel round bars square bars Flat bars Rectangles Bars Rods, 25NiCrMoV12-7 Forged forging steel rings seamless rolled rings, 25NiCrMoV12.7 Forged Forging Steel Hubs housing shell Sleeves Bushes Bushing Cases Hollow Bars,1.6962 Forged Forging Steel Discs Disks Blocks plates, 25NiCrMoV127 Forged Forging Steel Pipe Tubes Tubings Piping Shells Casings Case barrels Housings. 25NiCrMoV127 Forged Forging Steel Gas Steam Turbine Rotors Shafts,25NiCrMoV12-7 Forged Forging Gas Compressor Turbine Blades turbine Vane steel Flat Rectangles Bars, 25NiCrMoV12.7 Forged Forging Steel gas steam Turbine Guide Rings,seal rings Labyrinth Rings Packing Seal Diaphragm & Seal Ring Rotor End Rings contours Casing Rings,,25NiCrMoV127 Forged forging Gas Steam Turbine Valve Spindles/Stems/Rods,25NiCrMoV12.7 Forging Forged Gas Steam Turbine Doubled-headed Double end Studs Fasteners Bolts

Our 1.6962,25NiCrMoV12.7,25NiCrMoV12-7,25NiCrMoV127 forged steel parts is normal melting by Basic Electric Furnace (EAF, AOD, VOD) or + Electroslag remelting. (ESR) AS PER CLIENTS NEEDS

Chemical composition for 1.6962,25NiCrMoV12.7 forged steel gas turbine rotor shafts as follows

Carbon (C%) Min: 0,22 Max: 0,28

Manganese (Mn%) ≤ 0,06 ≤ 0,06

Silicon (Si%) ≤ 0,06

Phosphorus (P%) ≤0,004

Sulfur (S%) ≤0,003

Chrome (Cr%) Min: 1,50 Max: 2,00

Nickel (Ni%) Min: 2,80 Max: 3,20

Molybdenum (Mo%) Min: 0,40 Max: 0,60

Vanadium (V%) Min: 0,05 Max: 0,15

The following properties of 25NiCrMoV12.7 forging turbine blade flat bars at room temperature must be demonstrated by the following tests

Tensile strength, Rm: 850- 1000MPa

The yield point, Rp0,2: >700 MPa Properties of samples tested

longitudinally: Elongation, A:> 15%

Reduction > 40%

Charpy test :minimum 80J

25NiCrMoV12-7 forging steel turbine parts at elevated temperatures - the yield strength is as follows

Temperature 200℃ - Rp0,2: >625 MPa

Temperature 250℃ - Rp0,2: >600 MPa

Temperature 300℃ - Rp0,2: >580 MPa

Temperature 350℃ - Rp0,2: >550 MPa

Temperature 400℃ - Rp0,2: >510 MPa

Temperature 450℃ - Rp0,2: >480 MPa

Temperature 500℃ - Rp0,2: >400 MPa

We could produce forged steel 25NiCrMoV12.7 turbine rotor shafts in High,middle,low press steam turbine rotor,generator rotor, 35MW,50WM,60WM,70WM steam turbine rotor;

We have following inspection equipment to inspection all our 25NiCrMoV12-7 forging steel gas steam turbine rotor shafts

Tensile press

Charpy pendulum (up to – 90ºC)

Hardness testers

Scale

Thermometer

Spectrometer

Scales

Temperature control thermocouples

Continuous monitoring systems and process recording (heating, ring rolling and heat treatment)

Measuring laser

Pyrometer

Hardness testers

Laser measure

Comparators

Gauges

Micrometres

Bore gauges

UT equipment

MT equipment

Laser tracker

Fluorescent particles for liquid penetrant inspection

Radius gauges

Threaded plugs

Parallelism measuring devices

Roughness testers

Thickness gauges

Gauge blocks and rods

Light meters

Mass weight

Goniometers