Description

Jiangsu Liangyi professional manufacturer of Nimonic ALloy 86, Nimonic 86, ALloy 86,Nickel Alloy 86 open die forging parts and seamless rolled steel forged rings from china

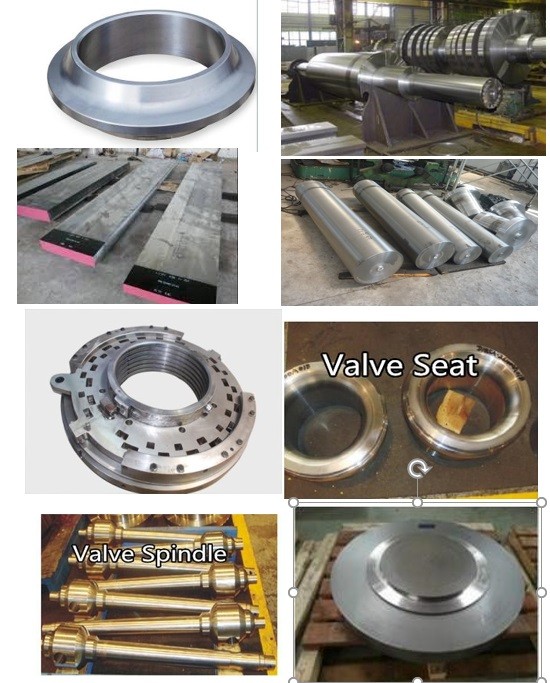

Following is the shape of Nimonic ALloy 86, Nimonic 86, ALloy 86,Nickel Alloy 86,nimonic86 forging steel material that we could do is:Nimonic 86 Forged Steel round bars square bars Flat bars Rectangles Bars Rods,Nimonic ALloy 86 Forged forging steel rings seamless rolled rings,Nimonic 86 Forged Forging Steel Hubs housing shell Sleeves Bushes Bushing Cases Hollow Bars,Nickel Alloy 86 Forged Forging Steel Discs Disks Blocks plates,ALloy 86 Forged Forging Steel Pipe Tubes Tubings Piping Shells Casings Case barrels Housings.

Following is forging products of Nimonic ALloy 86, Nimonic 86, ALloy 86,Nickel Alloy 86,nimonic86 material that is used in following industry

Nimonic ALloy 86 Forged Forging Gas Compressor Turbine Blades steel Flat Rectangles Bars

Nimonic 86 Forged Forging Gas steam turbine disks, turbine impeller,turbine blisk,turbine discs

ALloy 86 Forging Steel Forging Forged Gas Steam Turbine Doubled-headed Double end Studs Fasteners Bolts bolting

Nickel Alloy 86 Forging Steel gas steam Turbine Guide Rings,seal rings Labyrinth Rings Packing Seal Diaphragm & Seal Ring Rotor End Rings contours Casing Rings

ALloy 86 Forged Forging Steel Gas Steam turbine diaphragm diapharagm nozzles

Nimonic 86 Forged Forging Gas Turbine LPT 1st & 2st 2nd Stg Stage Turbine Case Casings

Nimonic 86 Forged Forging Steel power plant steam turbine control reheat valve disc Disk

ALloy 86 Forged forging Gas Steam Turbine Valve Spindles/Stems/Rods,

ALloy 86 Forging Steel Gas Steam Turbine MSV/GV/CV/CRV Valve Seats, Valve Cores, Valve Sleeves Spools,,Main Steam Valve Covers Bonnets Sleeves

Nimonic 86 forged material for nuclear power such as :Flow limiter Venturi forgings (steam generator),Forged tubes for pressurizer surge line,reactor nozzles and primary pump fly wheels, divider plates for steam generator,Latch housings, rod travel housings and funnel extension,end ring and rotor stack plate forgings,bearing housings and stator end cap and closure ring forgings,Containment plates, rings and closure heads,Waste Flasks and Mounting Skirt,RPV Upper Shell and HSG Shell,Shell Strakes and Transition Cones,Pressure Components,Lifting Pin Tools and Trunnions,Pressuriser Upper Head and Upper Shell,Steam Drumhead and Lifting Pintles

NIMONIC Alloy 86 is nickel-chromium-molybdenum alloy. Alloy 86 has good formability and weldability with exceptional resistance to oxidation and scaling to 1050°C (1920°F). Alloy 86 is quite rare due to its "Cerium" addition although it is widely used in afterburners and heat treating furnaces,Nimonic 86 has been developed to provide amaterial with good workability, duc tility andweldability, high creep strength and exceptionally good

cyclic oxidation resistance at 1050°C. The alloy is of the solid solution type and it is intended principally for use

in high temperature applications such as gas turbinecombustion chambers, afterburner parts and heattreatment furnace equipmen

The forgings nimonic 86 forged parts shall be free from defects such as cracks, flakes, seams, segregation, non-metallic inclusionsand other defects which may affect the utility of the forgings.

Chemical composition of Nimonic ALloy 86, Nimonic 86, ALloy 86,Nickel Alloy 86,nimonic86 forging turbine parts is as

Carbon.................................................................................0.05

Chromium ............................................................................25.0

Molybdenum........................................................................10.0

Magnesium........................................................................0.015

Cerium.................................................................................0.03

Nickel............................................................................Balance*

mechanical property of for Nimonic ALloy 86, Nimonic 86, ALloy 86,Nickel Alloy 86,nimonic86 forged round bars is as follow

roperties Metric Imperial

Tensile strength(annealed) 825 MPa 120 ksi

Yield strength(annealed) 410 MPa 59 ksi

Elongation at Break 42% 42%

Modulus of Elasticity 210 GPa 30500 ksi

FOllowing is testing standard of our Nimonic ALloy 86, Nimonic 86, ALloy 86,Nickel Alloy 86,nimonic86 forged steel turbine parts

ASTM E10-12: Standard Test Method for Brinell hardness of Metallic Materials;

ASTM A370-12: Standard Test Methods and Definitions for Mechanical Testing of Steel Products;

ASTM E23-07a: Standard Test Methods for Notched Bar Impact Testing of Metallic Materials;

AMS 2315G: Determination of Delta Ferrite Content,

ASTM E45-05: Standard Test Methods for Determining the Inclusion Content of Steel,

ASTM E112-10: Standard Test Methods for Determining Average Grain Size,

ASTM E837: Standard Test Method for Determining Residual Stresses by the Hole-Drilling Strain-Gage Method,

Welcome your inquiry of Nimonic ALloy 86, Nimonic 86, ALloy 86,Nickel Alloy 86,nimonic86 forging parts

Following is the shape of Nimonic ALloy 86, Nimonic 86, ALloy 86,Nickel Alloy 86,nimonic86 forging steel material that we could do is:Nimonic 86 Forged Steel round bars square bars Flat bars Rectangles Bars Rods,Nimonic ALloy 86 Forged forging steel rings seamless rolled rings,Nimonic 86 Forged Forging Steel Hubs housing shell Sleeves Bushes Bushing Cases Hollow Bars,Nickel Alloy 86 Forged Forging Steel Discs Disks Blocks plates,ALloy 86 Forged Forging Steel Pipe Tubes Tubings Piping Shells Casings Case barrels Housings.

Following is forging products of Nimonic ALloy 86, Nimonic 86, ALloy 86,Nickel Alloy 86,nimonic86 material that is used in following industry

Nimonic ALloy 86 Forged Forging Gas Compressor Turbine Blades steel Flat Rectangles Bars

Nimonic 86 Forged Forging Gas steam turbine disks, turbine impeller,turbine blisk,turbine discs

ALloy 86 Forging Steel Forging Forged Gas Steam Turbine Doubled-headed Double end Studs Fasteners Bolts bolting

Nickel Alloy 86 Forging Steel gas steam Turbine Guide Rings,seal rings Labyrinth Rings Packing Seal Diaphragm & Seal Ring Rotor End Rings contours Casing Rings

ALloy 86 Forged Forging Steel Gas Steam turbine diaphragm diapharagm nozzles

Nimonic 86 Forged Forging Gas Turbine LPT 1st & 2st 2nd Stg Stage Turbine Case Casings

Nimonic 86 Forged Forging Steel power plant steam turbine control reheat valve disc Disk

ALloy 86 Forged forging Gas Steam Turbine Valve Spindles/Stems/Rods,

ALloy 86 Forging Steel Gas Steam Turbine MSV/GV/CV/CRV Valve Seats, Valve Cores, Valve Sleeves Spools,,Main Steam Valve Covers Bonnets Sleeves

Nimonic 86 forged material for nuclear power such as :Flow limiter Venturi forgings (steam generator),Forged tubes for pressurizer surge line,reactor nozzles and primary pump fly wheels, divider plates for steam generator,Latch housings, rod travel housings and funnel extension,end ring and rotor stack plate forgings,bearing housings and stator end cap and closure ring forgings,Containment plates, rings and closure heads,Waste Flasks and Mounting Skirt,RPV Upper Shell and HSG Shell,Shell Strakes and Transition Cones,Pressure Components,Lifting Pin Tools and Trunnions,Pressuriser Upper Head and Upper Shell,Steam Drumhead and Lifting Pintles

NIMONIC Alloy 86 is nickel-chromium-molybdenum alloy. Alloy 86 has good formability and weldability with exceptional resistance to oxidation and scaling to 1050°C (1920°F). Alloy 86 is quite rare due to its "Cerium" addition although it is widely used in afterburners and heat treating furnaces,Nimonic 86 has been developed to provide amaterial with good workability, duc tility andweldability, high creep strength and exceptionally good

cyclic oxidation resistance at 1050°C. The alloy is of the solid solution type and it is intended principally for use

in high temperature applications such as gas turbinecombustion chambers, afterburner parts and heattreatment furnace equipmen

The forgings nimonic 86 forged parts shall be free from defects such as cracks, flakes, seams, segregation, non-metallic inclusionsand other defects which may affect the utility of the forgings.

Chemical composition of Nimonic ALloy 86, Nimonic 86, ALloy 86,Nickel Alloy 86,nimonic86 forging turbine parts is as

Carbon.................................................................................0.05

Chromium ............................................................................25.0

Molybdenum........................................................................10.0

Magnesium........................................................................0.015

Cerium.................................................................................0.03

Nickel............................................................................Balance*

mechanical property of for Nimonic ALloy 86, Nimonic 86, ALloy 86,Nickel Alloy 86,nimonic86 forged round bars is as follow

roperties Metric Imperial

Tensile strength(annealed) 825 MPa 120 ksi

Yield strength(annealed) 410 MPa 59 ksi

Elongation at Break 42% 42%

Modulus of Elasticity 210 GPa 30500 ksi

FOllowing is testing standard of our Nimonic ALloy 86, Nimonic 86, ALloy 86,Nickel Alloy 86,nimonic86 forged steel turbine parts

ASTM E10-12: Standard Test Method for Brinell hardness of Metallic Materials;

ASTM A370-12: Standard Test Methods and Definitions for Mechanical Testing of Steel Products;

ASTM E23-07a: Standard Test Methods for Notched Bar Impact Testing of Metallic Materials;

AMS 2315G: Determination of Delta Ferrite Content,

ASTM E45-05: Standard Test Methods for Determining the Inclusion Content of Steel,

ASTM E112-10: Standard Test Methods for Determining Average Grain Size,

ASTM E837: Standard Test Method for Determining Residual Stresses by the Hole-Drilling Strain-Gage Method,

Welcome your inquiry of Nimonic ALloy 86, Nimonic 86, ALloy 86,Nickel Alloy 86,nimonic86 forging parts