Description

Jiangsu Liangyi is professional manufacturer of 2.4733,Ni62Cr22W14Mo2 open die forging parts and seamless rolled steel forged rings from china

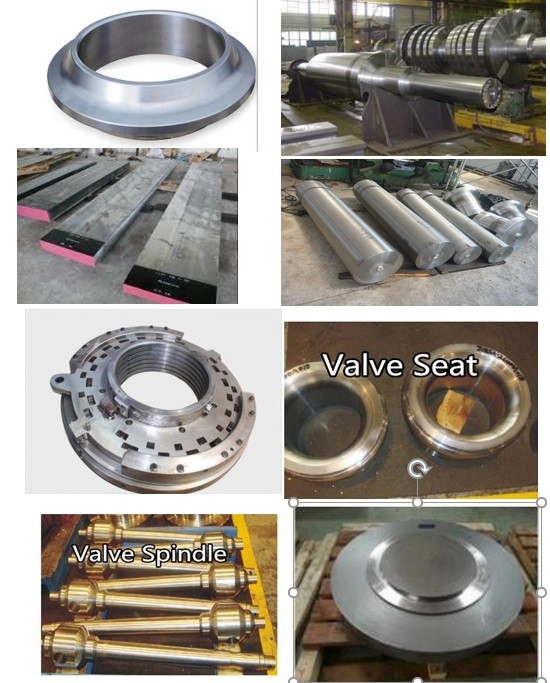

Following is the shape of 2.4733,Ni62Cr22W14Mo2 forging steel material that we could do is:2.4733 Forged Steel round bars square bars Flat bars Rectangles Bars Rods,Haynes Ni62Cr22W14Mo2 Forged forging steel rings seamless rolled rings,2.4733 Forged Forging Steel Hubs housing shell Sleeves Bushes Bushing Cases Hollow Bars,Ni62Cr22W14Mo2 Forged Forging Steel Discs Disks Blocks plates,Ni62Cr22W14Mo2 Forged Forging Steel Pipe Tubes Tubings Piping Shells Casings Case barrels Housings.

Following is forging products of 2.4733,Ni62Cr22W14Mo2 material that is used in following industry

Ni62Cr22W14Mo2 Forged Forging Gas Compressor Turbine Blades steel Flat Rectangles Bars

2.4733 Forged Forging Gas steam turbine disks, turbine impeller,turbine blisk,turbine discs

Ni62Cr22W14Mo2 Forging Steel Forging Forged Gas Steam Turbine Doubled-headed Double end Studs Fasteners Bolts bolting

Ni62Cr22W14Mo2 Forging Steel gas steam Turbine Guide Rings,seal rings Labyrinth Rings Packing Seal Diaphragm & Seal Ring Rotor End Rings contours Casing Rings

2.4733 Forged Forging Rolled Gas Steam Turbine Inner Outer Heat Shields

Ni62Cr22W14Mo2 Forged Forging Rolled Steel Gas Steam Turbine shrouds

2.4733 forging forged steel tube sheets, baffle plates, nozzles,flanges for heat exchanger

2.4733 material for furnace retorts, chains and fixtures, burner flame shrouds, recuperator internals, dampers, nitriding furnace internals, heat-treating baskets, grates, trays, sparger tubes, thermocouple protection tubes, cyclone internals

Ni62Cr22W14Mo2 Forged Forging Steel Gas Steam turbine diaphragm diapharagm nozzles

2.4733 forged forging hot working dies,tooling, die blocks,mould, mold.

2.4733 Forged Forging Gas Turbine LPT 1st & 2st 2nd Stg Stage Turbine Case Casings

2.4733 Forged Forging Steel power plant steam turbine control reheat valve disc Disk

Ni62Cr22W14Mo2 Forged forging Gas Steam Turbine Valve Spindles/Stems/Rods,

Ni62Cr22W14Mo2 Forging Steel Gas Steam Turbine MSV/GV/CV/CRV Valve Seats, Valve Cores, Valve Sleeves Spools,,Main Steam Valve Covers Bonnets Sleeves

Ni62Cr22W14Mo2 is a carbide-reinforced nickel-Chromium-tungsten-molybdenum alloy with an outstanding combination of strength, stability and corrosion resistance at very high temperatures. 2.4733 provides particularly good resistance to oxidation at temperatures above 980 ° C (1800 ° F). 2.4733 also provides good resistance to carburization and nitration.

2.4733 is a nickel base. Chromium gives resistance to high temperature corrosion. The oxidation is further enhanced by the micro-addition of the rare earth element lanthanum. 2.4733is largely responsible for the strength of the tungsten and molybdenum alloy, together with the high carbon content of the alloy. The creep resistance of the material has been optimized by controlling the boron content.

The combination of high temperature strength and resistance to creep, stress rupture and corrosion makes the 2.4733alloy attractive for service at temperatures above 980 ° C. Potential applications include land-based gas turbines, thermal and petrochemical processing, heat treatment, and equipment and components for ore and metal refining

2.4733 combines properties which make it ideally suited for a wide variety of component applications in the aerospace and power industries. It is used for combustion cans, transition ducts, flameholders, thermocouple sheaths, and other important gas turbine components. In the chemical process industry, 2.4733 is used for catalyst grid supports in ammonia burners, high-strength thermocouple protection tubes, high-temperature heat exchangers, ducts, high-temperature bellows, and various other key process internals.

Forgings 2.4733 maeterial shall be manufactured from steel produced by vacuum induction melting 1 electro-slag re-melting {VIM/ESR) or by vacuum induction melting 1 vacuum are re-melting (VIM/VAR) process.

The hot working shall be done in such a way that a uniform fine grained microstructure is achieved.

The 2.4733 forged material shall undergo the following heat treatment:

Solution Treatment - 1080 °C (1975 °F) for 8 hours + air cool or oil/ water quench

Precipitation Heat Treatment (As per BS HR2) - 700 °C (12230 °F) for 16 hours + air cool

Chemical composition of 2.4733,Ni62Cr22W14Mo2 forging turbine parts is as

Carbon (C%) Min: 0,05 Max: 0,15

Manganese (Mn%) Min: 0,30 Max: 1,00

Silicon (Si%) Min: 0,25 Max: 0,75

Phosphorus (P%) 0,02 max

Sulfur (S%) 0,015 max

Chrome (Cr%) Min: 20,0 Max: 24,0

Copper (Cu%) ≤ 0,50

Molybdenum (Mo%) Min: 1,00 Max: 3,00

Aluminum (Al%) Min: 0,2 Max: 0,5

Titanium (Ti%) ≤ 0,10

Tungsten (W%) Min: 13,0 Max: 15,0

Boron (B%) max 0,015

Cobalt (Co%) ≤ 5,00

Iron (Ferrum) (Fe%) ≤3

Lanthanum (La%) Min: 0,005 Max: 0,050

mechanical property of for 2.4733,Ni62Cr22W14Mo2 forged round bars is as follow

Ultimate Tensile Strength Min 758 Mpa

0.2 % Yield Strength MIN 310 Mpa

Elongation in % min 40%

Hardness HB 241 max

For NDT test for all our 2.4733,Ni62Cr22W14Mo2 forging parts, All Our NDT personnel are PCN and SNT-TC-1A qualified and certified in Non-Destructive Testing to level 2 or 3.All Our Level III and Level II industry certified NDT engineering team is trained inconventional and advanced techniques including radiography, ultrasonic, dye penetrant &magnetic particle to evaluate the material properties of a 2.4733,Ni62Cr22W14Mo2 forging material without damage.

All our 2.4733,Ni62Cr22W14Mo2 forging material will have following testing procedure

Visual inspections – Direct and Indirect

Magnetic particle

Dye penetrant – Visible and Fluorescent

Ultra-sonic testing

Radiograph

Metallurgical Testing

Macro & micro

Grain size determination

Charpy Impact testing

V notch Charpy

Hardness testing including micro and

macro Vickers tests

Tensile testing

Microscope imaging

Welcome your inquiry of 2.4733,Ni62Cr22W14Mo2 forging parts

Following is the shape of 2.4733,Ni62Cr22W14Mo2 forging steel material that we could do is:2.4733 Forged Steel round bars square bars Flat bars Rectangles Bars Rods,Haynes Ni62Cr22W14Mo2 Forged forging steel rings seamless rolled rings,2.4733 Forged Forging Steel Hubs housing shell Sleeves Bushes Bushing Cases Hollow Bars,Ni62Cr22W14Mo2 Forged Forging Steel Discs Disks Blocks plates,Ni62Cr22W14Mo2 Forged Forging Steel Pipe Tubes Tubings Piping Shells Casings Case barrels Housings.

Following is forging products of 2.4733,Ni62Cr22W14Mo2 material that is used in following industry

Ni62Cr22W14Mo2 Forged Forging Gas Compressor Turbine Blades steel Flat Rectangles Bars

2.4733 Forged Forging Gas steam turbine disks, turbine impeller,turbine blisk,turbine discs

Ni62Cr22W14Mo2 Forging Steel Forging Forged Gas Steam Turbine Doubled-headed Double end Studs Fasteners Bolts bolting

Ni62Cr22W14Mo2 Forging Steel gas steam Turbine Guide Rings,seal rings Labyrinth Rings Packing Seal Diaphragm & Seal Ring Rotor End Rings contours Casing Rings

2.4733 Forged Forging Rolled Gas Steam Turbine Inner Outer Heat Shields

Ni62Cr22W14Mo2 Forged Forging Rolled Steel Gas Steam Turbine shrouds

2.4733 forging forged steel tube sheets, baffle plates, nozzles,flanges for heat exchanger

2.4733 material for furnace retorts, chains and fixtures, burner flame shrouds, recuperator internals, dampers, nitriding furnace internals, heat-treating baskets, grates, trays, sparger tubes, thermocouple protection tubes, cyclone internals

Ni62Cr22W14Mo2 Forged Forging Steel Gas Steam turbine diaphragm diapharagm nozzles

2.4733 forged forging hot working dies,tooling, die blocks,mould, mold.

2.4733 Forged Forging Gas Turbine LPT 1st & 2st 2nd Stg Stage Turbine Case Casings

2.4733 Forged Forging Steel power plant steam turbine control reheat valve disc Disk

Ni62Cr22W14Mo2 Forged forging Gas Steam Turbine Valve Spindles/Stems/Rods,

Ni62Cr22W14Mo2 Forging Steel Gas Steam Turbine MSV/GV/CV/CRV Valve Seats, Valve Cores, Valve Sleeves Spools,,Main Steam Valve Covers Bonnets Sleeves

Ni62Cr22W14Mo2 is a carbide-reinforced nickel-Chromium-tungsten-molybdenum alloy with an outstanding combination of strength, stability and corrosion resistance at very high temperatures. 2.4733 provides particularly good resistance to oxidation at temperatures above 980 ° C (1800 ° F). 2.4733 also provides good resistance to carburization and nitration.

2.4733 is a nickel base. Chromium gives resistance to high temperature corrosion. The oxidation is further enhanced by the micro-addition of the rare earth element lanthanum. 2.4733is largely responsible for the strength of the tungsten and molybdenum alloy, together with the high carbon content of the alloy. The creep resistance of the material has been optimized by controlling the boron content.

The combination of high temperature strength and resistance to creep, stress rupture and corrosion makes the 2.4733alloy attractive for service at temperatures above 980 ° C. Potential applications include land-based gas turbines, thermal and petrochemical processing, heat treatment, and equipment and components for ore and metal refining

2.4733 combines properties which make it ideally suited for a wide variety of component applications in the aerospace and power industries. It is used for combustion cans, transition ducts, flameholders, thermocouple sheaths, and other important gas turbine components. In the chemical process industry, 2.4733 is used for catalyst grid supports in ammonia burners, high-strength thermocouple protection tubes, high-temperature heat exchangers, ducts, high-temperature bellows, and various other key process internals.

Forgings 2.4733 maeterial shall be manufactured from steel produced by vacuum induction melting 1 electro-slag re-melting {VIM/ESR) or by vacuum induction melting 1 vacuum are re-melting (VIM/VAR) process.

The hot working shall be done in such a way that a uniform fine grained microstructure is achieved.

The 2.4733 forged material shall undergo the following heat treatment:

Solution Treatment - 1080 °C (1975 °F) for 8 hours + air cool or oil/ water quench

Precipitation Heat Treatment (As per BS HR2) - 700 °C (12230 °F) for 16 hours + air cool

Chemical composition of 2.4733,Ni62Cr22W14Mo2 forging turbine parts is as

Carbon (C%) Min: 0,05 Max: 0,15

Manganese (Mn%) Min: 0,30 Max: 1,00

Silicon (Si%) Min: 0,25 Max: 0,75

Phosphorus (P%) 0,02 max

Sulfur (S%) 0,015 max

Chrome (Cr%) Min: 20,0 Max: 24,0

Copper (Cu%) ≤ 0,50

Molybdenum (Mo%) Min: 1,00 Max: 3,00

Aluminum (Al%) Min: 0,2 Max: 0,5

Titanium (Ti%) ≤ 0,10

Tungsten (W%) Min: 13,0 Max: 15,0

Boron (B%) max 0,015

Cobalt (Co%) ≤ 5,00

Iron (Ferrum) (Fe%) ≤3

Lanthanum (La%) Min: 0,005 Max: 0,050

mechanical property of for 2.4733,Ni62Cr22W14Mo2 forged round bars is as follow

Ultimate Tensile Strength Min 758 Mpa

0.2 % Yield Strength MIN 310 Mpa

Elongation in % min 40%

Hardness HB 241 max

For NDT test for all our 2.4733,Ni62Cr22W14Mo2 forging parts, All Our NDT personnel are PCN and SNT-TC-1A qualified and certified in Non-Destructive Testing to level 2 or 3.All Our Level III and Level II industry certified NDT engineering team is trained inconventional and advanced techniques including radiography, ultrasonic, dye penetrant &magnetic particle to evaluate the material properties of a 2.4733,Ni62Cr22W14Mo2 forging material without damage.

All our 2.4733,Ni62Cr22W14Mo2 forging material will have following testing procedure

Visual inspections – Direct and Indirect

Magnetic particle

Dye penetrant – Visible and Fluorescent

Ultra-sonic testing

Radiograph

Metallurgical Testing

Macro & micro

Grain size determination

Charpy Impact testing

V notch Charpy

Hardness testing including micro and

macro Vickers tests

Tensile testing

Microscope imaging

Welcome your inquiry of 2.4733,Ni62Cr22W14Mo2 forging parts