Description

Jiangsu Liangyi is professional manufacturer of Invar 42,ALLOY 42,UNS K94100,NILO 42 open die forging parts and seamless rolled steel forged rings from china

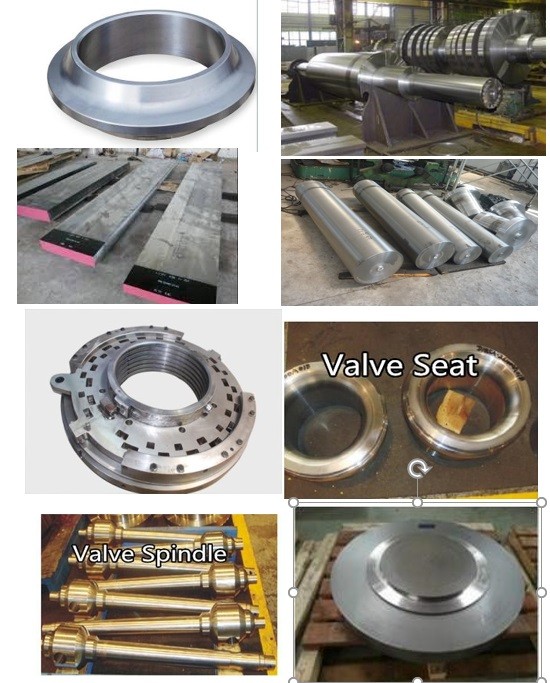

Following is the shape of Invar 42,ALLOY 42,UNS K94100,NILO 42 forging steel material that we could do is:ALLOY 42 Forged Steel round bars square bars Flat bars Rectangles Bars Rods,Invar 42 Forged forging steel rings seamless rolled rings,NILO 42 Forged Forging Steel Hubs housing shell Sleeves Bushes Bushing Cases Hollow Bars,1.3817 Forged Forging Steel Discs Disks Blocks plates,UNS K94100 Forged Forging Steel Pipe Tubes Tubings Piping Shells Casings Case barrels Housings.

Invar 42 a 41% nickel-iron controlled expansion alloy which has been used in a wide variety of glass-to-metal sealing applications.

While the expansion properties of this alloy most closely match 1075 glass, it has also been used in seals for the 0120 and 0010 glasses. It may also be used with hard glasses if a thin edged tubular seal is used. For seals that are not hydrogen annealed prior to sealing, a variation of this alloy containing small additions fo titanium, Glass Sealing 42 Gas-Free, has been used to promote gas-free sealing characteristics.

All our Invar 42,ALLOY 42,UNS K94100,NILO 42 forged material must give the material a required purity necessary for the application in following melting methods one is triple melted material,VIM+ESR+VAR., the another one is double melted material,VIM+VAR.

FOllowing is chemical compostion of Invar 42,ALLOY 42,UNS K94100,NILO 42 forged steel rings

Element

Carbon 0.05 max

Nickel 41.0

Iron Balance

Silicon 0.20

Manganese 0.40

Following of Invar 42,ALLOY 42,UNS K94100,NILO 42 forging parts heat treatment mechanical property Delivery condition :

Metallurgical Condition Annealed, Descaled

Yield Strength KSI (MPa) 36 (248)

Tensile Strength KSI (MPa) 71 (490)

Hardness HB 130

Elongation 50mm >40

The quality of Jiangsu products Invar 42,ALLOY 42 forging workshop is based on its “state-of-the-art”technology of its laboratories for metallurgy and chemistry. we perform

a range of tests, including mechanical property tests, chemical and environmental analyses, metallographic, macrographic and micrographic tests using optical and electronic microscopes.

, all HASTELLOY B3 forging steel turbine rotor shafts materials are tested and certified in accordance with nternational standards and Customer’s specifications, using any combination of the following methods: UT-RT-HT-PT-MT-VT-DT

The following details shall be furnished in the test certificate of finished Invar 42,ALLOY 42,UNS K94100,NILO 42 forged steel:

Heat No. , and melting type.

Dimensional inspection

Details of heat treatment cycle followed.

Results of chemical analysis including tramp elements.

Results of mechanical tests, including hardness test. All individual values shall be reported.Results of ultrasonic tests

Results of surface crack examination

Confirmation of the visual inspection

Confirmation of the verification inspection

Results of additional tests called for in the drawing/order.

Welcome your inquiry of Invar 42,ALLOY 42,UNS K94100,NILO 42forging forged steel parts

Following is the shape of Invar 42,ALLOY 42,UNS K94100,NILO 42 forging steel material that we could do is:ALLOY 42 Forged Steel round bars square bars Flat bars Rectangles Bars Rods,Invar 42 Forged forging steel rings seamless rolled rings,NILO 42 Forged Forging Steel Hubs housing shell Sleeves Bushes Bushing Cases Hollow Bars,1.3817 Forged Forging Steel Discs Disks Blocks plates,UNS K94100 Forged Forging Steel Pipe Tubes Tubings Piping Shells Casings Case barrels Housings.

Invar 42 a 41% nickel-iron controlled expansion alloy which has been used in a wide variety of glass-to-metal sealing applications.

While the expansion properties of this alloy most closely match 1075 glass, it has also been used in seals for the 0120 and 0010 glasses. It may also be used with hard glasses if a thin edged tubular seal is used. For seals that are not hydrogen annealed prior to sealing, a variation of this alloy containing small additions fo titanium, Glass Sealing 42 Gas-Free, has been used to promote gas-free sealing characteristics.

All our Invar 42,ALLOY 42,UNS K94100,NILO 42 forged material must give the material a required purity necessary for the application in following melting methods one is triple melted material,VIM+ESR+VAR., the another one is double melted material,VIM+VAR.

FOllowing is chemical compostion of Invar 42,ALLOY 42,UNS K94100,NILO 42 forged steel rings

Element

Carbon 0.05 max

Nickel 41.0

Iron Balance

Silicon 0.20

Manganese 0.40

Following of Invar 42,ALLOY 42,UNS K94100,NILO 42 forging parts heat treatment mechanical property Delivery condition :

Metallurgical Condition Annealed, Descaled

Yield Strength KSI (MPa) 36 (248)

Tensile Strength KSI (MPa) 71 (490)

Hardness HB 130

Elongation 50mm >40

The quality of Jiangsu products Invar 42,ALLOY 42 forging workshop is based on its “state-of-the-art”technology of its laboratories for metallurgy and chemistry. we perform

a range of tests, including mechanical property tests, chemical and environmental analyses, metallographic, macrographic and micrographic tests using optical and electronic microscopes.

, all HASTELLOY B3 forging steel turbine rotor shafts materials are tested and certified in accordance with nternational standards and Customer’s specifications, using any combination of the following methods: UT-RT-HT-PT-MT-VT-DT

The following details shall be furnished in the test certificate of finished Invar 42,ALLOY 42,UNS K94100,NILO 42 forged steel:

Heat No. , and melting type.

Dimensional inspection

Details of heat treatment cycle followed.

Results of chemical analysis including tramp elements.

Results of mechanical tests, including hardness test. All individual values shall be reported.Results of ultrasonic tests

Results of surface crack examination

Confirmation of the visual inspection

Confirmation of the verification inspection

Results of additional tests called for in the drawing/order.

Welcome your inquiry of Invar 42,ALLOY 42,UNS K94100,NILO 42forging forged steel parts