Description

Jiangsu Liangyi professional manufacturer of Stainless Steel AISI 418 Grade 418 AMS 5616 (UNS S41800,Alloy 615,AISI 615) open die forging parts and seamless rolled steel forged rings from china

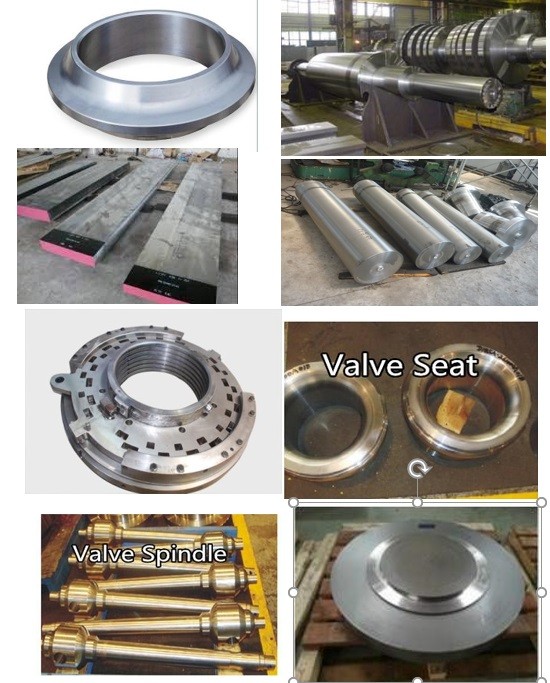

Following is the shape of Stainless Steel AISI 418 Grade 418 AMS 5616 (UNS S41800,Alloy 615,AISI 615) forging steel material that we could do is:AISI 418 Forged Steel round bars square bars Flat bars Rectangles Bars Rods,UNS S41800 Forged forging steel rings seamless rolled rings,AMS 5616 Forged Forging Steel Hubs housing shell Sleeves Bushes Bushing Cases Hollow Bars,AISI 615 Forged Forging Steel Discs Disks Blocks plates,AMS 5616 Forged Forging Steel Pipe Tubes Tubings Piping Shells Casings Case barrels Housings.

Following is forging products of Stainless Steel AISI 418 Grade 418 AMS 5616 (UNS S41800,Alloy 615,AISI 615) material that is used in following industry

AISI 418 Forged Forging Gas Compressor Turbine Blades steel Flat Rectangles Bars,Steam turbine buckets and vanes

AMS 5616 Forged Forging Gas steam turbine disks, turbine impeller,turbine blisk,turbine discs

UNS S41800 Forging Steel Forging Forged Gas Steam Turbine Doubled-headed Double end Studs Fasteners Bolts

Alloy 615 Forging Steel gas steam Turbine Guide Rings,seal rings Labyrinth Rings Packing Seal Diaphragm & Seal Ring Rotor End Rings contours Casing Rings

AISI 615 forged forging steel pump case, pump impeller, pump wear rings, pump shafts

UNS S41800 forged forging steel valve bonnet, valve body, valve closure, valve stems, valve seat rings, valve core, valve discs

The melting methods of AISI 418 forged steam turbine blade steel is as follows: The Steel shall be made using the basic electric furnace process with either the Electro-Slag Re-Melt (ESR) or Vacuum- Arc-Re-Melt(VAR) process.

AISI 418 Grade 418 AMS 5616 is chromium-nickel-tungsten martensitic alloy. AISI 418 is a deep hardening grade used for application where high resistance to tempering and stress-corrosion cracking are needed. Greek Ascoloy is engineered for use in high-stress components up to 649 C. Typical heat treatment at 980C -1010C, followed by air or oil quenching (depending on material thickness) and 2-hour tempering twice at minimum 620C gives this material a superior creep strength and resistance to stress-corrosion cracking and tempering. Strength at the higher temperature is superior to that of the standard 12Cr type steel. Grade 418 is often used for Compressor Components, Turbine Blades, Steam Turbine Buckets, and Elevated Temperature Bolts. (

FOllowing is chemical compostion of Stainless Steel AISI 418 Grade 418 AMS 5616 (UNS S41800,Alloy 615,AISI 615) forged steel flat bars

Element Min Max

Carbon, C 0.15 0.2

Manganese, Mn - 0.5

Silicon, Si - 0.5

Sulfur, S - 0.03

Phosphorus, P – 0.04

Chromium, Cr 12 14

Nickel, Ni 1.8 2.2

Copper, Cu - 0.5

Molybdenum, Mo - 0.5

Tungsten, W 2.5 3.5

Aluminum, Al - 0.15

Tin, Sn - 0.05

Nitrogen, N - 0.8

AISI 418 forging steel turbine blade flat bars heat treat way is as follows:

AISI 418 is process annealed by heating to 1300 °F, holding at temperature approximately 4 hours, and air cooling. The resultant hardness is approximately 280 BHN. To obtain maximum softness and complete relief of stresses, a cyclic anneal is required. This treatment consists of heating to 1450 °F for 2 to 4 hours followed by furnace cooling to 800 °F least 200 °F. The material is then reheated to 1250/1300 °F for a minimum of 12 hours and air cooled. The resultant hardness is approximately 255 BHN.

Hardening and Tempering of UNS S41800 forged steel parts

An austenizing temperature of 1700/1800 °F is generally used to harden Alloy 418 followed by quenching in either oil or air depending upon section size and design. Heavy sections, or parts of intricate design are usually preheated at 1200/1400 °F prior to hardening. The resultant hardness is approximately 448/472 BHN.

Tempering should be done as soon as possible following the hardening treatment. The effect of tempering temperature on hardness after oil treating from 1750 °F

Mechanical properties of Stainless Steel AISI 418 Grade 418 AMS 5616 (UNS S41800,Alloy 615,AISI 615)forged round bars shall be tested at room temperature (23 ± 5degree),

Properties Metric Imperial

Tensile strength 895 MPa 130000 psi

Yield strength (@strain 0.200 %) 725 MPa 105000 psi

Modulus of elasticity 190-210 GPa 27557- 30457 ksi

Poisson’s ratio 0.27-0.30 0.27-0.30

Elongation at break 15% 15%

Hardness, Rockwell C 25 25

For melting Stainless Steel AISI 418 Grade 418 AMS 5616 (UNS S41800,Alloy 615,AISI 615)forging steel material, we have following melting equipment

60 t Electric Arc Furnace (EAF) / Power 40 MVA

2 Ladle Furnace (LF)

2 Tank Degassing VD - VOD type

Pits for bottom pouring

ESR Plant (max weight 32 t)

In order to make forging and make heat treatment Stainless Steel AISI 418 Grade 418 AMS 5616 (UNS S41800,Alloy 615,AISI 615) forging RIngs, we have following production equipment

Forging Process:3200/4200/6000 t Open die presses

Manipulators, Lifting Capacity up to 60 t

Heating Forging Furnaces, Max Capacity 150 t

Furnaces for Hydrogen Bake-Out Up to 14 m

Heat Treatment Semi-automatic Heat Treatment System Quality Heat Treatment

Furnaces Max lenght 18 m Quenching tanks up to 16 m

Welcome your inquiry of Stainless Steel AISI 418 Grade 418 AMS 5616 (UNS S41800,Alloy 615,AISI 615) forging forged steel parts